Selective Wave Soldering Machine: The Choice Of More Manufacturers

1. The application fields of selective wave soldering

Selective wave soldering machine is a high-quality and high-precision assembly technology that is suitable for soldering through-hole components in high-end electronic products. In recent years, it has gradually become a popular trend in the field of PCB through-hole soldering, with applications ranging from high-precision electronic products, automotive electronics, switch power supplies, digital cameras, printers, and more.

In addition, selective wave solder machine is more efficient and cost-effective than traditional wave soldering machine because it uses less solder and reduces the time required for the soldering process. Here, we will introduce the process and advantages of selective wave solder equipment.

2. The Process Flow of Selective Wave Soldering

2.1 What is selective wave soldering machine?

Selective wave soldering machine is a soldering process used in electronics manufacturing to selectively solder components on a printed circuit board (PCB). Unlike traditional wave soldering equipment that immerse entire PCBs in molten solder, selective wave soldering machine use a targeted solder wave to selectively apply solder to specific areas of the PCB. This allows for more precise control over the soldering process, particularly when working with complex, high-density PCBs.

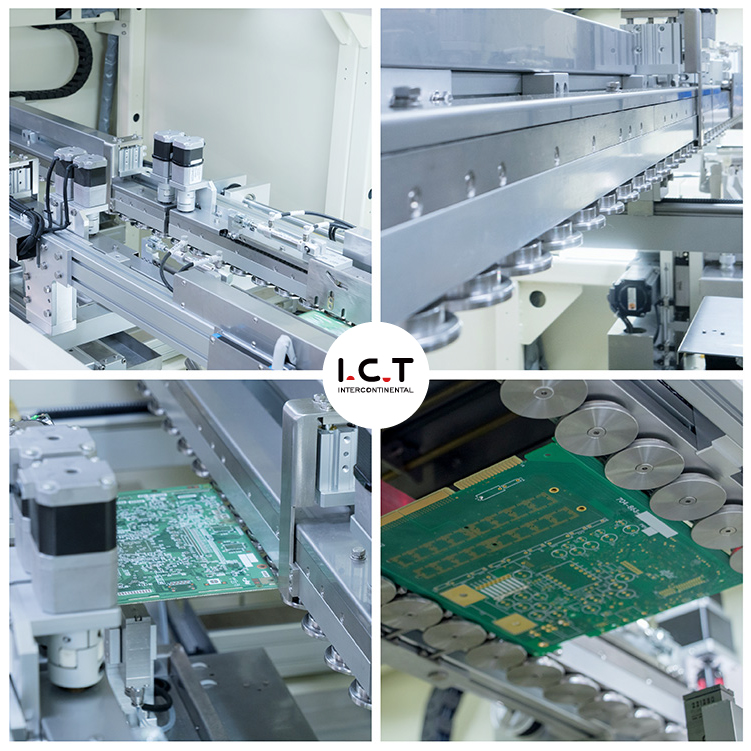

The I.C.T online selective wave soldering machine is a high-performance equipment assembled in China through independent research and development. Based on an absolutely stable process flow and replicable parameters, the I.C.T selective wave soldering machine configuration includes modules for flux spraying, preheating, and soldering, as well as a segmented conveyor system that can meet current and future manufacturing process requirements. The selective wave soldering machine does not require downtime and can change products in multi-wave processes, with the ability to operate up to two nozzles, up to five lower preheating modules, and optional upper convection heating. It is highly suitable for connection to assembly lines and peripheral equipment, connection to traceability systems for process control, and can significantly increase throughput without increasing floor space requirements by adding optional dual-pot and/or dual-track functions according to customer requirements.

2.2 How does a selective soldering machine work?

A selective soldering machine is used to solder specific parts of a printed circuit board while avoiding other parts that do not require soldering. The machine works by first placing the printed circuit board on a conveyor belt that moves it through the wave soldering process. A nozzle then applies a preheating flux to the areas that will be soldered. Next, a solder wave is introduced to the specific areas that require soldering. The wave is created by a molten solder pot below the conveyor belt. The temperature and height of the wave can be adjusted to suit the specific requirements of the PCB.Once the PCB has passed through the wave, it moves on to a cooling station where it is cooled to prevent any damage. Finally, it exits the machine and is ready for further processing.

3. Key Techniques of Selective Wave Soldering Machine

The process flow of selective wave solder machine generally consists of three parts: flux spraying system, preheating system, and soldering system. By setting the program of the equipment, the soldering points to be soldered can be sequentially sprayed with flux, then preheated by the preheating module, and finally soldered point by point by the soldering module.

3.1 Flux system

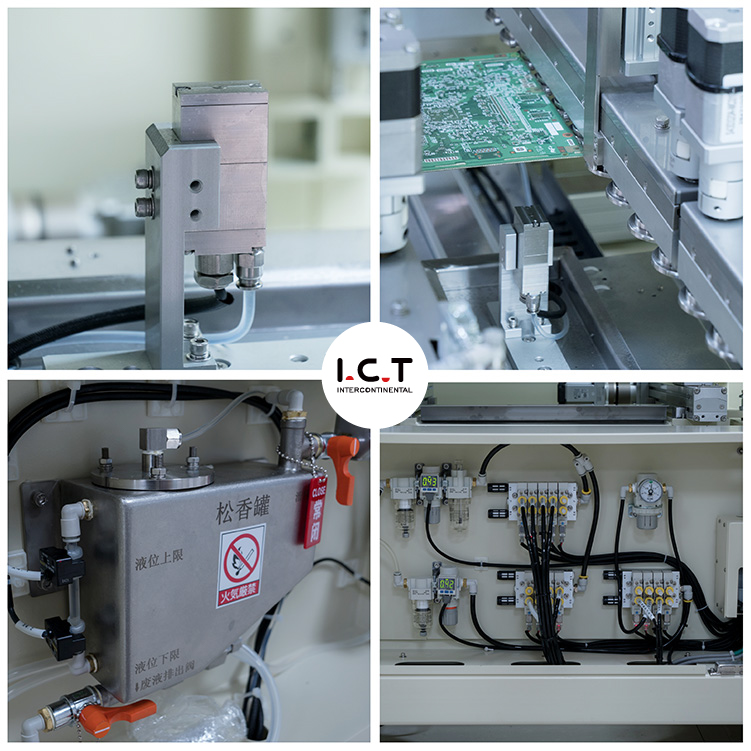

- The soldering assistant system of the selective soldering machine adopts German high-frequency pulse injection valve, and the X and Y axes are driven and controlled by servo motors for precise positioning.

- The soldering assistant nozzle has a diameter of 130 μm and is made of stainless steel. The soldering assistant storage tank can hold 1-2 L

- There is a tray under the nozzle to collect soldering assistant waste, which is convenient for cleaning and maintenance.

- All pneumatic components use the Japanese SMC brand to ensure the accuracy, speed, and high-quality soldering assistant process of the spray.

3.2 Preheat system

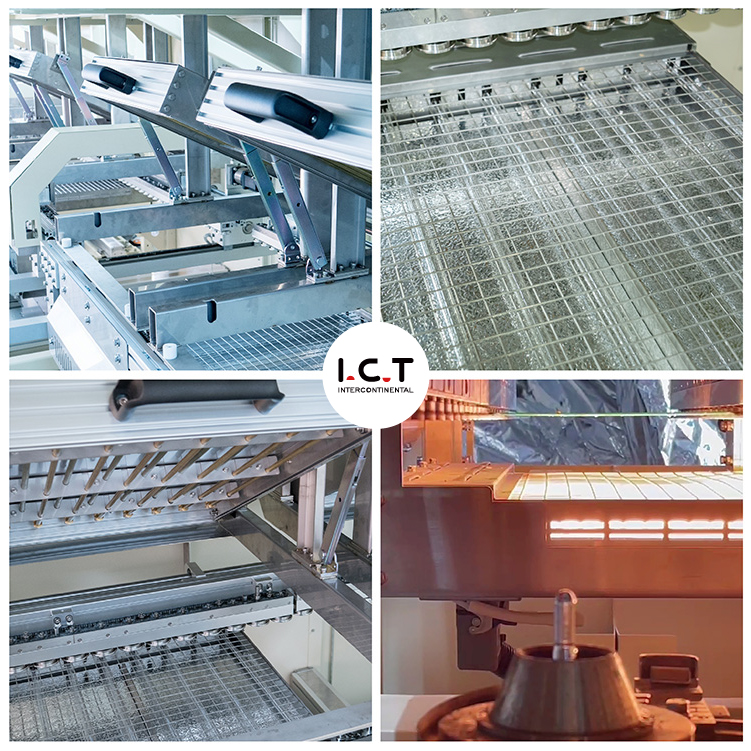

- The I.C.T selective wave soldering machine adopts the standard bottom infrared and top hot air heating method, and the preheating position is adjustable.

- All-round high-temperature cotton design ensures more stable temperature.

3.3 Soldering system

- I.C.T selective wave soldering machine is equipped with the Swedish “PRECIMETER” brand electromagnetic pump to ensure stable and reliable peak values.

- Both top and bottom heating systems.

- The soldering module includes dual solder cylinders, and the Z and Y axes are adjustable. The dual cylinder module can provide double the production capacity when soldering PCB, creating substantial added value for the production process.

- Adopts the Hikvision camera, visualizing the soldering process and allowing soldering details to be traced. The amount of solder and the height of the solder wave can be monitored in real-time.

- Laser detection system for soldering wave height. German “SICK” non-contact laser sensor is used to ensure

- Automatic cleaning function of the spray nozzle is standard, and the cleaning frequency can be flexibly adjusted.

3.4 Nitrogen system

1. N2 online heating system allows the temperature to be set on the computer desk, achieving perfect wetting of solder and reducing solder dross.

3.5 Transmission system

- Compared with traditional chain, our selective wave soldering machine uses roller transportation.

- Customized guide rails are thickened to bear 20KG.

- The track width is programmatically adjustable to accommodate PCB production with a maximum width of 500 x 500mm.

- Equipped with PCBA side clamping and top clamping system to ensure the stability of the board.

3.6 Control system

- Design of the control electrical cabinet complies with CE standards.

- The Keyence KV 7500 PLC and Keyence module high-end bus control system ensure the stability and scalability of the system.

3.7 Operating system

- Equipped with an industrial computer and a 22-inch display monitor,

- Operating system features an intuitive visual interface that guides programming mode, allowing for quick CCD programming.

- The nozzle type is automatically recognized.

- Multiple languages such as Chinese, English, Japanese, and Russian can be easily switched between.

3.8 Intelligence system

Intelligent MES system, designed in compliance with Industry 4.0, with WIFI connectivity, online software upgrades, and traceable soldering data, allowing for confirmation of the process for each solder joint.

4. Optional Features

4.1 Dual Cylinder Device

The optional dual cylinder module can provide double the productivity when soldering PCBs, creating substantial added value for the production process.

4.2 Automatic Solder Supply Device

During production, the solder surface height is constantly monitored and solder is automatically added when it reaches a certain liquid level to ensure compliance with the liquid level height requirements, eliminating the need for manual solder addition and line stoppages.

4.3 Top Hot Air Convection Device

Top hot air convection heating ensures that the PCB remains constant and stable throughout the entire soldering process.

4.4 Offline Programming

- Save time on programming when switching machine types.

- Optimize the spraying soldering cycle time in advance.

- Simulate the spraying soldering path to estimate production capacity in advance.

4. Advantages of selective wave soldering machine

Selective wave soldering machine have several advantages over traditional wave soldering machine, including:

- High qualityl: Selective wave soldering machine offer better process control, as they can be programmed to apply solder only to specific areas of the PCB, reducing the risk of solder bridging or other defects.

- High reliability: Selective wave soldering machine have the ability to preheat the PCBs before soldering, reducing the thermal stress on the components and improving the overall reliability of the solder joints.

- High precision: Selective wave soldering machine use a spray nozzle to accurately apply the solder to the desired areas, allowing for precise and consistent soldering.

- High flexibility: Selective wave soldering machine can solder components on both sides of a PCB, allowing for increased flexibility in the design and layout of PCBs.

- Decline soldering slag: Selective wave soldering machine use less solder than traditional wave soldering machines, resulting in less dross, which is the waste material produced during the soldering process.

- Environmentally Friendly: Selective wave soldering machine use less solder, which reduce waste and help to protect the environment. Additionally, some models of selective wave soldering machine are designed to be lead-free, making them even more environmentally friendly.

Conclusion

I.C.T online selective wave soldering equipment is a high performance equipment developed and assembled in China. The combinations of the arrangement of different modules show only some of the possibilities of the extremely flexible I.C.T modular system concept, for higher flexibility or multiwave soldering machinefor high-volume processes.product changes without downtime even in multi-wave processes, parallel process due to the separation offluxing, preheating and soldering, operation of up to two spray heads, up to five lower preheating with optional upper convection heating, perfect for the connection to assembly stands and periphery, connection to traceability systems for process control.

Overall, selective wave soldering machine offer improved precision, flexibility, process control, and environmental friendliness compared to traditional wave soldering machine, making them a popular choice in modern electronics manufacturing.

Learn more about wave soldering machine, contact us now.

Ask a quesiton

I.C.T – Your Reliable Dearest Partner

For you we can provide Full SMT Solution, DIP Solution and PCBA Coating Solution with best quality and service.