SMT Line Solution

sMT Production Line Solution

Delivering Full Line Solutions to the entire SMT Market

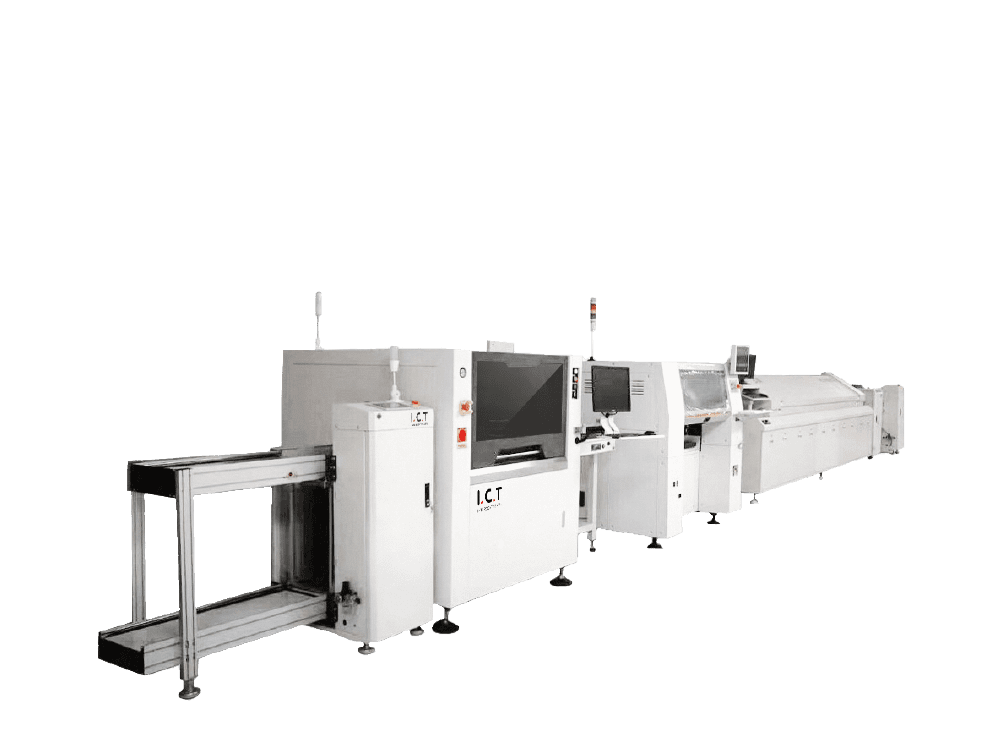

The main equipment are Stencil Printer, SMT Pick and Place Machine, Reflow Oven and SMT Handling Machine.

SMT Production Line Solutions: A Guide for Manufacturers

Surface mount technology (SMT) is a method of electronic assembly in which components are mounted directly onto the surface of a printed circuit board (PCB). This method has many advantages over traditional through-hole technology, including reduced assembly costs, faster production times, and smaller overall size.

SMT components are typically smaller and lighter than through-hole components, which means they require less material and labor to assemble. SMT components are also easier to handle and place, which speeds up the assembly process. Additionally, SMT boards are typically smaller than through-hole boards, which saves space on the board.

Application of SMT production line

SMT is widely used in the electronics industry, and it is the preferred method of assembly for many electronic devices. Some of the most common applications of SMT include:

- Consumer electronics, such as televisions, computers, and cell phones

- Industrial equipment, such as robots and medical devices

- Automotive electronics, such as car radios and navigation systems

- Military and aerospace applications

- LED Industry, such and led bulb, led strip, led moudle etc.

- Semiconductor

SMT is a versatile and efficient method of electronic assembly, and it is used in a wide variety of industries. If you are looking for a way to improve your manufacturing process, SMT is a great option.By following the tips in this guide, you can choose the right SMT production line for your needs and implement it successfully. Click here for More details

Benefits to Using SMT Production Line

- Reduced assembly costs: SMT production is generally less expensive than traditional through-hole technology. This is because SMT components are smaller and lighter, which means they require less material and labor to assemble.

- Faster production times: SMT production lines can typically produce more boards per hour than traditional through-hole lines. This is because SMT components are easier to handle and place, which speeds up the assembly process.

- Smaller overall size: SMT boards are typically smaller than through-hole boards. This is because SMT components do not require through-holes, which saves space on the board.

- Improved reliability: SMT boards are generally more reliable than through-hole boards. This is because SMT components are less likely to come loose or fall off the board.

Types of SMT production lines

There are many different types of SMT production lines available, each with its own advantages and disadvantages. The type of line you choose will depend on the volume of production you need, as well as the types of components you use.

Small-scale SMT production lines are typically used for low-volume production. These lines are typically less expensive than larger lines, but they also have lower production capacity.

- Medium-scale SMT production lines

Medium-scale SMT production lines are typically used for medium-volume production. These lines offer a good balance of cost and production capacity.

Large-scale SMT production lines are typically used for high-volume production. These lines are the most expensive, but they also have the highest production capacity.

How to choose the right SMT Production Line?

When choosing an SMT production line, there are a few factors you need to consider.

- The volume of production you need

- The types of components you use

- The max PCB size

- Your budget

Accordering to these factors, you can start to narrow down your choices. It is important to get quotes from several different suppliers before making a decision.

What equipment does the SMT production line include?

The main euipments in the SMT production line are:

- Pick and place machine: This machine places the components on the PCBs.

- Solder paste printer: This machine prints the solder paste on the PCBs.

- Reflow oven: This oven melts the solder paste and solders the components to the PCBs.

- PCB/ PCBA Cleaner: Clean the PCBs after soldering.

- PCB Handling Machine (PCB Conveyor and PCB Loader/unloader): Used to transport and position PCBs in an SMT production line.

If your universal production line needs more sophisticated testing equipment, there are AOI, SPI, AXI to option.

Installing and Training for SMT Production Line

Installing and training for smt production line, it`s an important step, as even a small mistake can lead to costly errors.

The installation process will vary depending on the type of line you have purchased. However, most lines will require some basic electrical and mechanical skills to install.

The training process will also vary depending on the type of line you have. However, most lines will require some basic training on how to use the equipment.

Monitoring and Adjusting SMT Production Line

Once your SMT production line is up and running, you need to monitor its performance and make adjustments as needed. It will help you ensure that your line is running efficiently and producing high-quality products.

There are a few things you need to monitor, including:

- The production rate

- The quality of the products

- The cost of production

Any problems be found, you need to be adjusted according to the actual situation. The Settings on the device may need to be adjusted or more training may be required for employees.

According to above tips, you can choose the right SMT production line according to your needing. implement it successfully, and monitor its performance to ensure that it is producing high-quality products.

I.C.T-Your Reliable Dearest Partner

Professional things need to be handed over to professional people.

I.C.T has strong R&D and integration capabilities in PCB, SMT, DIP, Coating, Dispensing, Intelligent Assembly, Industrial Software Applications and so on field. It helps more than 600 manufacturer built their SMT factory all over the world.

Here some success cases for your information:

Comments from global partners

If there is a need to optimize your SMT line services. Find out how I.C.T’s exclusive line assessment service can improve your operations.