Choosing Between IR and UV Curing Oven: A Comprehensive Guide

For those who are preparing to set up a production line, it is important to choose the machine that suits them. For example, a dispensing line or a coating line, how to choose a dispensing machine and a coating machine, and what model is needed requires a professional engineer to introduce it. And they will all need a curing oven. We have many types of curing ovens. From the principle of differentiation, there are IR curing ovens and UV curing ovens. How to choose? In this article, we will introduce them.

Principles of IR and UV Curing Oven

IR Curing Oven

The IR curing oven relies on a finned radiator and a stainless steel heating tube for heat, using a fan to create convection ventilation within the heating assembly. This process continuously heats the air, which interacts with the material, while maintaining a cycle of fresh air intake and moisture release. Simultaneously, the furnace gradually increases in temperature, preheating the mold.

UV Curing Oven

Ultraviolet (UV) curing involves UV energy emitted by a mercury discharge lamp being absorbed by a sensitizer, initiating a reaction in the monomer that solidifies it. The rate of this curing process is influenced by several factors:

- Chemical Composition: Each monomer’s curing rate varies based on the sensitizer, pigment, and chemical additives’ quantities and compositions.

- Coating Thickness: The curing process isn’t directly proportional to coating thickness. UV energy within a layer diminishes exponentially with depth. For instance, if 70% of the UV energy is absorbed in the top .001″ of coating, the subsequent .001″ absorbs only 7% of the initial amount. Thus, doubling the thickness necessitates a tenfold increase in UV intensity.

- UV Energy Density: Generally, curing speed escalates with UV energy per unit surface at a non-linear rate. A 200-watt per inch mercury lamp, when increased to 400 watts, could amplify the curing speed tenfold.

The sensitizer’s absorption of UV should align with wavelengths not absorbed by the monomer or pigment. Medium-pressure mercury or metal halide lamps should emit wavelengths compatible with the sensitizer’s absorption range.

Selecting the Appropriate Oven for Different Adhesives

Choosing the right oven for various adhesives is a critical decision impacting the curing process.

Which glues are suitable for IR oven?

Heat-cured glues: IR ovens are generally suitable for heat-cured glues because they require heat energy to activate and cure. This type of glue responds well to the thermal energy of IR radiation, making it suitable for use with an IR oven.

High-viscosity glues: Some high-viscosity glues require relatively high temperatures to cure. An IR oven can provide enough heat energy to allow these glues to cure quickly.

Thick-coat glues: Glues that require a deep cure may benefit from IR curing ovens, as they provide continuous heat that helps cure the entire coating.

Which glues are suitable for UV curing oven?

Light-curing glues: UV ovens are best for light-curing glues that require UV energy to cure quickly. These glues chemically react and solidify quickly upon exposure to specific wavelengths of UV light.

Surface-curing glues: Some glues need to cure quickly on the surface, so a UV oven can provide an efficient and fast curing process.

Fine curing requirements: For glues that require fine control and precise curing, a UV oven is usually more suitable because it can be precisely cured in a short time.

Role of Curing Oven in Coating and Dispensing Lines

In the field of SMT production, the curing oven is indispensable, because now most PCBAs require coating and dispensing, especially the production of mobile phones and motherboards, and coating production lines and dispensing production lines both There is a link of solidification. Currently, I.C.T has a variety of ovens for you to choose from, and has recently launched a vertical oven.

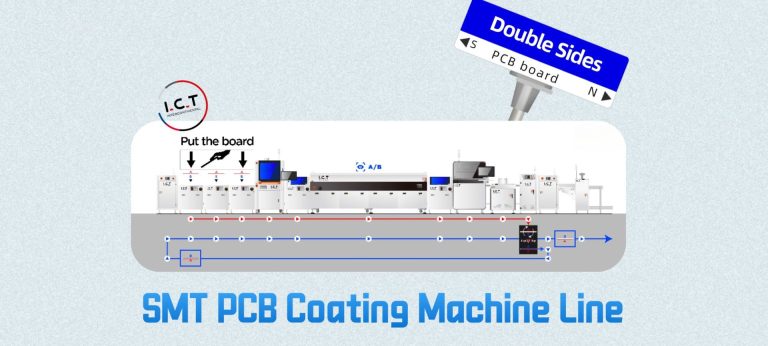

Overview of Coating and Dispensing Lines

Regarding coating lines, if you also have related needs and don’t know how to choose a coating machine, you can click on the link to learn. You can also contact us directly, we have a team of engineers to communicate with you. Coating machines include: I.C.T-T550, I.C.T-T550U, I.C.T-T600, I.C.T-T650. The dispensing machines include I.C.T-D600 and I.C.T-D1200. You can click on the link to view it if you are concerned about the selection of dispensing valves or the selection of coating valves.

Our equipment is designed and produced in accordance with European safety standards, and there are higher requirements for the safety of equipment use. And there is a CE certificate that complies with European standards.

When choosing a curing oven for different glues, always rely on professional advice and technical support. Whether your needs are IR curing or UV curing, I.C.T’s professional engineering team will provide you with comprehensive solutions to ensure the best curing effect and production efficiency. Contact us and let us help you choose the right oven for your application to improve product quality and productivity. Achieve better curing results and improve your manufacturing process.