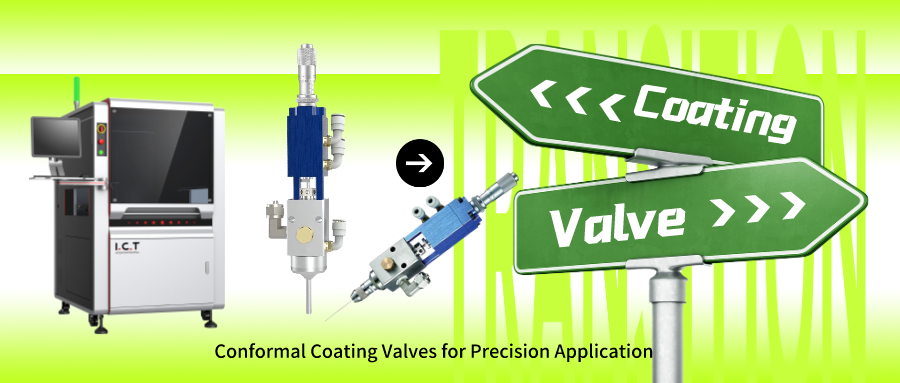

Exploring I.C.T’s Versatile Conformal Coating Valves

Conformal coating is a critical process in various industries, including electronics, lighting, energy, and life sciences, where precision and efficiency are paramount. Choosing the right coating valve can significantly impact the quality of the application. In this article, we’ll explore various conformal coating valves, specifically focusing on the C-0101, C-L101, PJ-01, PJ-01 (with plastic bucket), C-0100, D-0100, D-0300, and the W Series.

C-0101 Water Curtain Spray conformal Coating Valves

The C-0101 is a non-atomizing water curtain spray valve designed for low-viscosity solvent materials. It provides a clean and precise edge in coating applications, making it ideal for materials such as conformal coatings, UV adhesives, backfilling materials, and volatile substances.

C-0101 Specification:

- Dimension: L28 W28 H200mm

- Rotation angle: 0° or 90°

- Drive air pressure: 0.5~1.0Mpa

- Spraying width: 6~15mm

- Spraying thickness: 100um~350um

- Optimal viscosity range: 10~90Cps

- Weight: 500g

C-L101 Rotary Water Curtain Spray Valve

Like the C-0101, the C-L101 is a non-atomizing water curtain spray valve designed for low-viscosity solvent materials. It produces a precise edge without splashing or flashpoints, making it suitable for coatings like conformal coatings, UV adhesives, backfilling materials, and volatile substances.

C-L101 Specification:

- Dimension: L28 W28 H200mm

- Rotation angle: 0° or 90°

- Drive air pressure: 0.5~1.0Mpa

- Spraying width: 6~15mm

- Spraying thickness: 100um~350um

- Optimal viscosity range: 10~90Cps

- Weight: 500g

PJ-01 Injection Valve (Without Plastic Bucket)

The PJ-01 is designed for high-precision applications, including electronic packaging, lighting, energy, and life sciences. It’s suitable for accurate dispensing and coating, particularly on complex circuit boards. This valve can handle various materials, including red glue, liquids, and pastes.

PJ-01 Specification:

- Weight: 0.3Kg

- Driving pressure: 0.5~1.0Mpa

- Maximum operating frequency: 200 beats per second

- Minimum point diameter: 0.4mm

- Optimum viscosity range: 1-20000Cps

- Minimum driving pressure: 70Psi

- Valve body heating: 24V room temperature~150℃

- Open valve inlet pipe specifications: 6mm tube

- Matching: Optional glue nozzle

PJ-01 Injection Valve (With Plastic Bucket 30CC)

The PJ-01, with a 30cc plastic bucket, serves the same applications as the PJ-01 without the bucket. It’s highly precise and suitable for complex circuit board applications. It can dispense red glue, liquids, and pastes with precision.

PJ-01 Specification:

- Overall dimension: L60W26H120mm

- Weight: 0.3Kg

- Adjustable needle barrel specification: 30cc

- Driving pressure: 0.5~1.0Mpa

- Maximum operating frequency: 200 beats per second

- Minimum point diameter: 0.4mm

- Optimum viscosity range: 1-20000Cps

- Minimum driving pressure: 70Psi

- Valve body heating: 24V room temperature~150℃

- Open valve inlet pipe specifications: 6mm tube

- Matching: Optional glue nozzle

C-0100 Non-Rotating Film Valve

The C-0100 Conformal Coating Valves, unlike pneumatic atomizing valves, offers precise edge definition without air pressure involvement. By controlling the pressure tank’s inlet pressure, you can choose the film’s width. It effectively addresses issues with atomizing drift and fast-drying adhesives.

C-0100 Specification:

- Dimensions: L25W25H219.5mm

- Driving pressure: 0.3Mpa

- Optimum viscosity range: 100~200Cps

- Weight: 0.3Kg

- Spraying width: 6~12mm

- Spraying thickness: 250~450um

- Atomizing width: 10~15mm

D-0100 Precision Valve

The D-0100 features a unique fluid-sealing structure, driven by compressed air. This design minimizes seal replacement frequency, making it a low-maintenance option. It’s suitable for various fluid dispensing, including UV adhesives, encapsulating materials, silicones, epoxies, and surface coatings.

D-0101 Specification:

- Glue needle nozzle specification: 0.2~2mm

- Driving pressure: 0.3Mpa

- Optimum viscosity range: 30~6500Cps

- Weight: 0.26Kg

- Minimum line width: 1mm

- Minimum dispensing diameter: 1.5um

- Minimum dispensing space is up to 1.2mm

D-0300 Dispensing Valve

The D-0300 Conformal Coating Valves is designed for precision fluid dispensing. It operates at a low driving pressure and can handle a range of materials, including acrylics, silicones, epoxies, and UV adhesives. It’s ideal for applications where accuracy and consistency are crucial.

D-0300 Specification:

- Driving pressure: 0.3Mpa

- Fluid pressure: 0~0.5Mpa

- Optimum viscosity range: 0~3500Cps

- Weight: 0.28Kg

- Applicable fluid: Acrylic acid, silicon, epoxy, UV glue

- Spraying thickness: 50~200um

- Atomizing width: 3~6mm

W Series: Needle Design Atomization Valves

The W Series offers needle design valves that leave zero residue. They are easy to clean without disassembly and provide adjustable fluid and air pressure for various coating materials, achieving excellent atomization effects.

W-0300 Small Atomization Valve Specification:

- Driving pressure: 0.3Mpa

- Fluid pressure: 0~0.5Mpa

- Optimum viscosity range: 0~3500Cps

- Weight: 0.28Kg

- Applicable fluid: Acrylic acid, silicon, epoxy, UV glue

- Spraying thickness: 50~200um

- Atomizing width: 3~5mm

W-1500 Small Atomization Valve Specification:

- Driving pressure: 0.3Mpa

- Fluid pressure: 0~0.5Mpa

- Optimum viscosity range: 0~3500Cps

- Weight: 0.28Kg

- Applicable fluid: Acrylic acid, silicon, epoxy, UV glue

- Spraying thickness: 50~200um

- Atomizing width: 5~15mm

W-3000 Large Atomization Glue Specification:

- Driving pressure: 0.3Mpa

- Fluid pressure: 0~0.5Mpa

- Optimum viscosity range: 0~3500Cps

- Weight: 0.28Kg

- Applicable fluid: Acrylic acid, silicon, epoxy, UV glue

- Spraying thickness: 100~200um

- Atomizing width: 10~30mm

Analyzing the Options:

When choosing a conformal coating valve, it’s essential to consider the specific application requirements. The C-0101 and C-L101 are well-suited for low-viscosity solvent materials, providing precise and clean coating edges. PJ-01, with or without a plastic bucket, offers high-precision dispensing for complex applications. C-0100 and D-0100 Conformal Coating Valves are options to consider for various materials, while D-0300 is an excellent choice for precision dispensing. The W Series offers needle design atomization valves for residue-free applications, with different sizes for various needs. Make your choice based on your material, precision, and coating requirements.

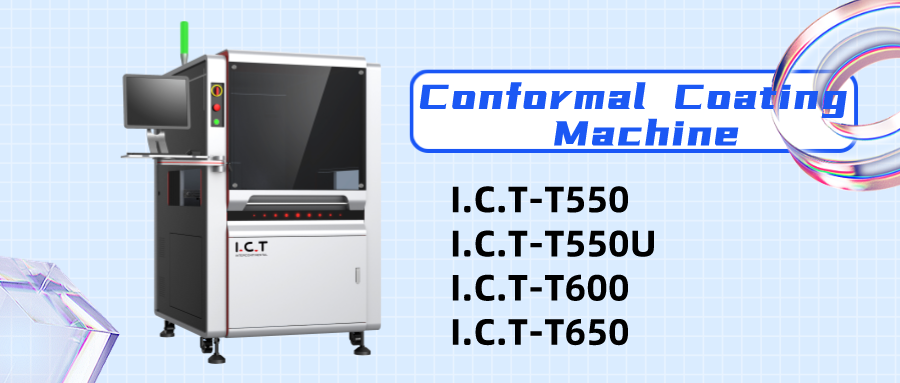

Conformal Coating Valves are integral components in I.C.T’s Conformal Coating machines, allowing for the precise application of coatings tailored to your specific adhesive and product requirements. Our coating machines, including the I.C.T-T550, I.C.T-T550U, I.C.T-T600, and I.C.T-T650, are equipped with a range of valve options to cater to the diverse needs of your production line. Whether you’re working with different adhesives or a variety of products, we have the right valve solutions to ensure consistent, high-quality results. Choose the perfect valve to match your unique application needs and maximize the efficiency and accuracy of your conformal coating processes.

More Details

If you are intrigued by the world of coating and dispensing machines and wish to explore their differences, feel free to click on the coating and dispensing machine link to learn more. Our comprehensive insights will help you make informed decisions for your electronic assembly needs.

If you require our professional engineers to design a tailored Coating production line, we are more than willing to assist you. I.C.T team is dedicated to creating a production setup that perfectly matches your requirements and ensures optimal performance.