PCBA Coating Line Solution

Conformal PCBA Coating Line Solution

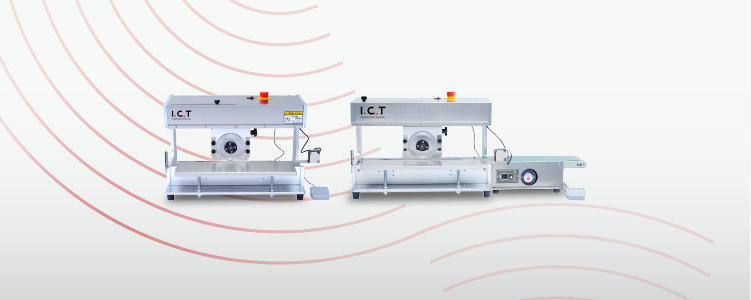

The main equipments are conveyor, coating machine and IR/UV oven machine etc.

What is Conformal PCBA Coating Line:

A conformal PCBA coating line is a system that applies a protective coating to printed circuit boards (PCBs). The coating helps to protect the PCB from environmental factors such as moisture, dust, and corrosion. It can also improve the electrical performance of the PCB by providing insulation and shielding.

Conformal coating lines can be either manual or automated. Manual lines are typically used for small-batch production, while automated lines are used for high-volume production. Automated lines can be more efficient and consistent than manual lines, but they can also be more expensive.

A Basic configuration of PCBA coating line:

- PCBA loader and unloader: This machine loads and unloads the PCBs from the coating line.

- PCBA coating conveyor: This conveyor moves the PCBs through the coating line.

- Conformal coating machine: This machine applies the conformal coating to the PCBs.

- UV curing oven: This oven cures the conformal coating.

- Inspection Conveyor: This station inspects the PCBs for defects.

The basic configuration of PCBA coating with the Return function:

- PCBA Coating Lift: It`s used to lift and move PCBAs (printed circuit board assemblies) during the coating process. It is typically a robotic arm that is equipped with a vacuum cup or other gripping mechanism.

- PCBA Conveyor: It`s used to transport PCBAs through the coating process.

- PCBA Coating Machine:It`s used to apply the conformal coating to the PCBA.

- Solder Paste Inspection:It`s used to inspect the PCBA for solder paste defects. This is done before the coating process so that any defects can be corrected before the coating is applied.

- IR Curing Oven: It`s used to cure the conformal coating. It uses infrared radiation to heat the coating, which causes it to harden.

- Inspection Conveyor: It`s used to inspect the PCBA after the coating process. This is done to ensure that the coating has been applied evenly and correctly.

- PCBA Fipper: It`s used to flip the PCBA over during the coating process. This is necessary to ensure that the coating is applied to both sides of the board.

the steps involved in the conformal PCBA coating Line process:

- The PCBs are first cleaned to remove any dirt, grease, or other contaminants.

- The PCBs are then dipped or sprayed with the conformal coating material.

- The excess coating is then removed.

- The PCBs are then cured, usually in an oven or under ultraviolet (UV) light.

What`s the Benefits of Conformal PCBA Coating Line?

There are many benefits to using conformal coating on PCBAs. Some of the most notable benefits include:

- Protection from environmental factors: Conformal coatings can help to protect PCBAs from a variety of environmental factors, including moisture, dust, corrosion, and extreme temperatures.

- Improved electrical performance: Conformal coatings can help to improve the electrical performance of PCBAs by providing insulation and shielding. This can help to prevent electrical shorts and other problems.

- Increased reliability: Conformal coatings can help to increase the reliability of PCBAs by protecting them from damage. This can help to extend the lifespan of PCBAs and reduce the need for repairs.

- Reduced maintenance costs: Conformal coatings can help to reduce the maintenance costs of PCBAs by making them less susceptible to damage. This can save businesses money in the long run.

Main application field of Conformal PCBA Coating Line:

- LED industry: outdoor display and kitchen lighting, stage lighting etc.

- Instrument industry: water meter, electricity meter, gas meter etc.

- Automotive Electronics: Automotive bus (CAN, LIN) products, anti-lock braking system (ABS) etc.

- Household appliances: air conditioning, washing machine, water heater, induction cooker, microwave oven, rice cooker etc.

- Instrument industry: electronic scale, alcohol detector etc.

- Security access control: smoke fire detector, alarm, access control intercom, security check machine etc.

- Medical industry: B ultrasonic color ultrasound X-ray magnetic resonance examination and treatment equipment etc.

- Communication industry: router, switch communication, base station etc.

- Rail transit: Control system such as signal instrument of subway and high-speed railway etc.

- State Grid: power generation, transmission and substation monitoring and measurement etc.

- Shipping industry:

- Military industry:

- Aerospace:

About Conformal Coating Valves

A Conformal Coating Machine is an essential tool that requires precise Conformal Coating Valves. The choice of valves should be tailored to your specific adhesive and product requirements to ensure optimal performance. In a comprehensive article that we have prepared, we delve into the various Conformal Coating Valves available, offering a detailed analysis of their features and applications. You can explore these options and make an informed decision for your coating needs. For an in-depth understanding of these valves, check out our article Conformal Coating Valves and discover how the right valve selection can make a significant difference in your conformal coating processes.

If you seek to enhance the dependability, efficiency, and longevity of your PCBAs, consider investing in a conformal coating line with comprehensive service and maintenance options. If there is a need to optimize your SMT line services. Find out how I.C.T’s exclusive line assessment service can improve your operations.

Video For Your Information: