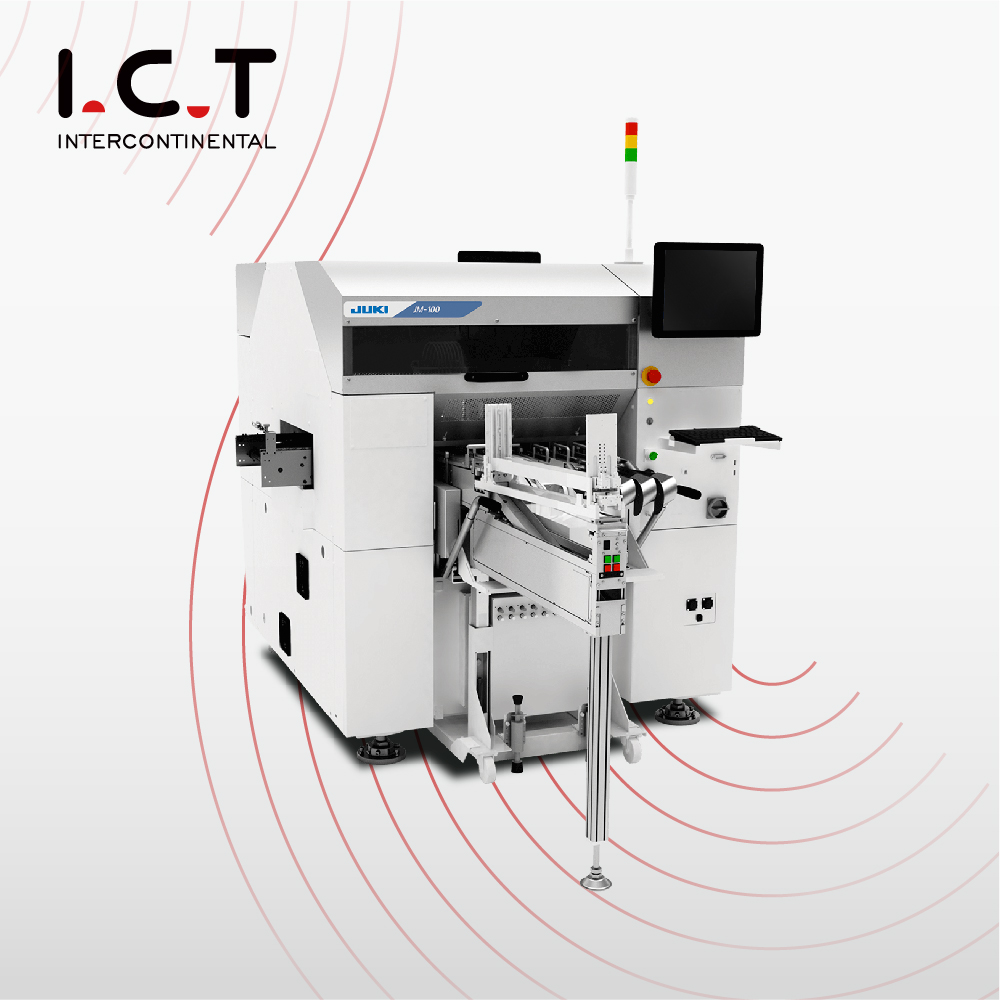

JUKI-JM100 | Automatic Odd-form Inserter

JUKI JM100 Odd-form Inserter: Precision powerhouse with shaped insertion, 6-nozzle efficiency, hybrid SMT/Through Hole capability, laser-align centering, and versatile feeders for optimal component integration.

For personalized assistance or to discuss how the JUKI JM100 can meet your unique needs, feel free to Contact Us directly.

Axial I.C.T-Z4020 | Radial I.C.T-Z3020

JUKI Series JM100 | JM50 | JM20

Odd Form OFM-2 | OFM-4 | OFM-4D | OFM-6 | OFM-6D

Eyelet Pin I.C.T-S7000

Description

JUKI-JM100 | Automatic Odd-form Inserter

Presenting the JUKI JM100 Odd-form Inserter: Redefining Precision in Component Integration

- Shaped Insertion Mastery: As an advanced Odd-form Inserter, the JUKI JM100 excels as a shaped insertion machine, seamlessly performing both insertion and placement concurrently, ensuring a streamlined production process.

- Hybrid SMT and Through Hole Placement: Elevate your manufacturing capabilities with the JUKI JM100, a hybrid SMT and Through Hole Placement Machine designed as an advanced model catering to larger and heavier components, as well as larger boards.

- Multi-Nozzle Precision: Featuring 6 nozzles per gantry (plus IC head on 3020V), this Odd-form Inserter has the remarkable capacity to place 6 components simultaneously, with dynamic centering on the fly, showcasing unparalleled efficiency.

- Precision Ball Screw Drive: Drive accuracy to new heights with the JUKI JM100’s high-precision, low-noise ball screw drive, incorporating Linear Encoders for optimal performance in component placement.

- Laser Precision Component Centering: Experience precision at every step with the JUKI JM100’s high-accuracy laser-align component centering, offering flexibility to select the centering method based on component type, shape, size, and material.

- Through Hole Expertise: Specializing in Through Hole Placement, the JUKI JM100 ensures precision with lead tip centering, making it a reliable choice for component integration.

- Lead Orientation Detection: The integrated laser sensor in the JUKI JM100 excels in lead tip detection, contributing to an improved insertion process and ensuring precise lead orientation.

- Versatile Bowl Feeders (MBF): Tailor your component feeding system with options like MBF (Fixed), MBF-C (Trolley), or MBF-L (for large components), providing adaptability to diverse production needs.

- Efficient Radial Feeders (MRF): Choose efficiency with options like MRF-S/M-L or snap-in MRF-LF radial feeders, adding further flexibility to the JUKI JM100’s advanced component feeding capabilities.

Step into the future of precision manufacturing with the JUKI JM100 Odd-form Inserter, where cutting-edge technology meets seamless integration for enhanced productivity and precision in every component placement.

Specification of JUKI JM100 Odd-form Inserter

- Board Size

– 50㎜×50㎜~410㎜×360㎜ to 80㎜×100㎜~800㎜×360㎜

- PCB Weight max.4kg

- Component Height 30mm

- Component Size

– Laser recognition 0603~□50mm

– Vision recognition □3mm~□50mm

- Insertion Speed Vacuum (JUKI Condition) 0.6 sec/parts

- Placement Accuracy (SMT)

– Laser recognition ±0.05mm(3σ)

– Vision recognition ±0.04mm

Please Contact Us directly for more specifications of the Odd-form Inserter

Enhancing SMT Assembly Efficiency: Essential Equipment and Expert Support

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.Additional information

| Model | Multi Task Platform JM-100 |

|---|---|

| Board Size | 1 time clumping: 410*360mm |

| Component Height | max.30mm |

| Component Size | 0603-50MM |

| Placement Speed | 16,000 CPH |

| Head | 8 |

| Machine dimension (W×D×H) | 1500*1500*1450mm |

| Mass (Approximately) | 1300kg |