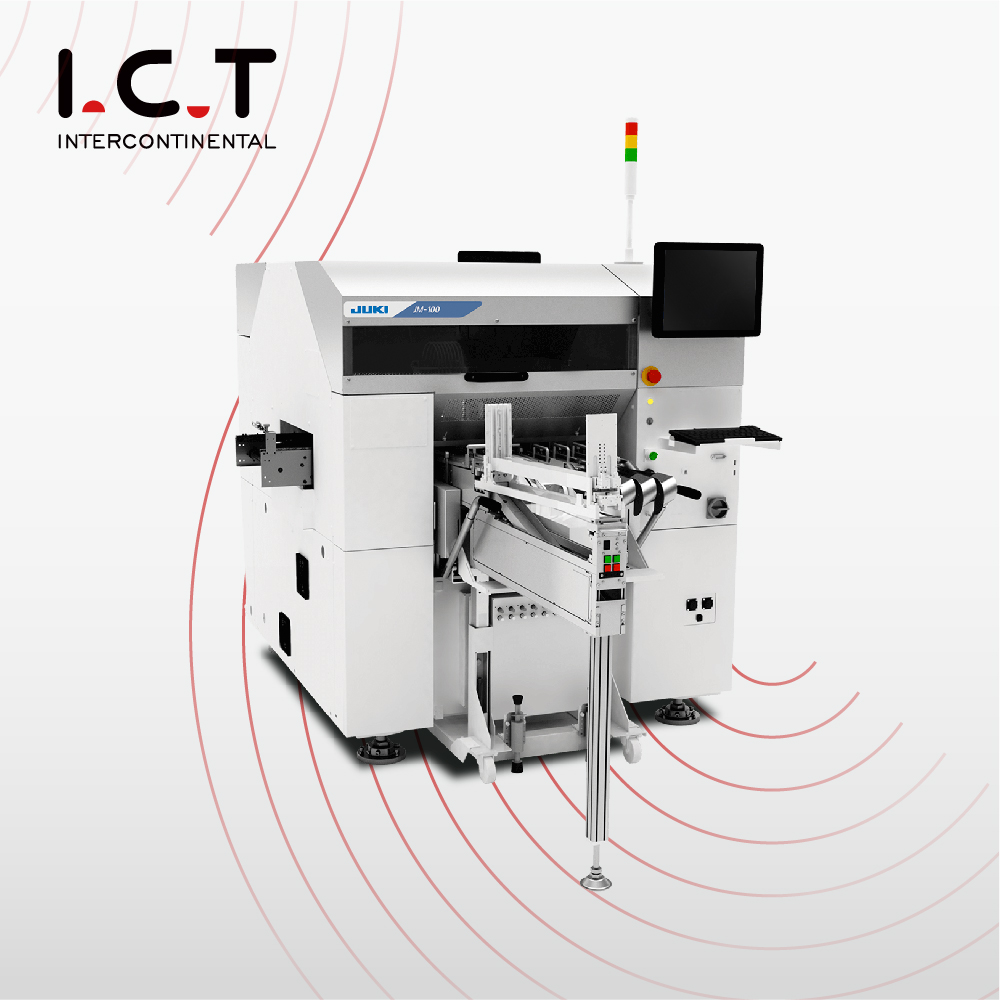

JUKI-JM50 | PCB Automatic Insertion Machine

Maximize your PCB assembly efficiency with the JUKI JM50 PCB Automatic Insertion Machine, a highly versatile and efficient solution for seamlessly inserting axial components. Elevate your production capabilities by integrating this advanced machine into your assembly line.

For personalized assistance or to discuss how the JUKI JM50 can meet your unique needs, feel free to Contact Us directly.

Axial I.C.T-Z4020 | Radial I.C.T-Z3020

JUKI Series JM100 | JM50 | JM20

Odd Form OFM-2 | OFM-4 | OFM-4D | OFM-6 | OFM-6D

Eyelet Pin I.C.T-S7000

Description

JUKI-JM50 | PCB Automatic Insertion Machine

Experience unparalleled efficiency with the JM-50 PCB Automatic Insertion Machine, a multitask platform designed for reliable, high-quality automatic insertion with exceptional value. This advanced PCB automatic insertion machine is engineered to handle large components and shaped insertions concurrently, seamlessly combining plug-in and SMD capabilities through its 4-nozzle SMT head.

Key Features:

- Multitask Platform: The JM-50 excels as a multitask platform, ensuring seamless integration into your production line as a versatile PCB automatic insertion machine.

- Reliable, High-Quality Automatic Insertion: Benefit from unmatched reliability and high-quality automatic insertion, enhancing the overall performance of your PCB assembly process.

- Versatility for Large Components: Ideal for accommodating large components and shaped insertions, the JM-50 is equipped to handle diverse manufacturing needs as a specialized PCB automatic insertion machine.

- High-Mix Low-Volume Production: Tailored for high-mix, low-volume production, this PCB automatic insertion machine ensures optimal efficiency in varied production scenarios.

- Flexible Feeders: Embrace new, flexible feeders that expand the component range, offering superior productivity and facilitating faster changeovers.

- Wide Range of Applications: The JM-50 boasts a huge variety of applications, making it a versatile solution for different manufacturing requirements.

- New Mini Chuck Nozzles: The inclusion of new Mini Chuck Nozzles supports a wide range of components, reducing cycle time, lowering tooling costs, and simplifying programming.

- Largest Installed Base: Trusted by industry leaders, the JM-50 has the largest installed base, thanks to its high quality and unmatched reliability.

Elevate your production capabilities with the JM-50 PCB Automatic Insertion Machine, a cutting-edge solution that combines versatility, efficiency, and reliability for unparalleled performance in the electronics assembly process.

Specification of JUKI JM50 PCB Automatic Insertion Machine

- Board Size

– Single Clamp 50×50㎜~410×360㎜

– Double Clamp 50×50㎜~800×360㎜

- PCB Weight max.2kg

- Component Height 30mm

- Conveyor height 900㎜、950㎜

- Insertion Speed Vacuum (JUKI Condition) 0.8 sec/parts

- Machine dimension (WxDxH) 1,454×1,505×1,450㎜

Mass (approximately) 1,300kg

Please Contact Us directly for more specifications of the PCB Automatic Insertion Machine

Enhancing SMT Assembly Efficiency: Essential Equipment and Expert Support

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.Additional information

| Model | Multi Task Platform JM-50 |

|---|---|

| Board Size | 1 time clumping: 410*360mm |

| Component Height | max.30mm |

| Component Size | 0603-50MM |

| Placement Speed | 9,000 CPH |

| Head | 4 |

| Machine dimension (W×D×H) | 1454*1505*1450mm |

| Mass (Approximately) | 1300kg |