I.C.T AOI Solution & SMD X-Ray Counter

With the global industrial transformation, I.C.T entering Industry 4.0 intelligent MES system management helps customers improve production efficiency, shorten production cycle, and achieve comprehensive scientific traceability management, so as to quickly respond to market changes and enhance core competitiveness.

AOI optical inspection equipment for industry 4.0 to achieve centralized management, multi-equipment interconnection in SMT / DIP production line to detect PCBA patch and solder defects.

Now let’s look at the new products in details.

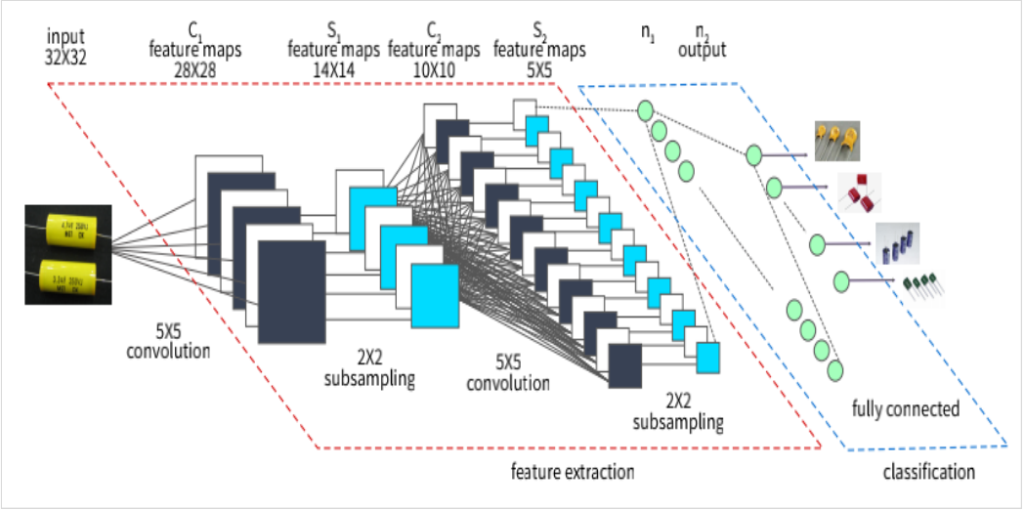

AOI AI Core Technology

Applying deep learning algorithms in the field of industrial inspection, big data optimized, intelligent minimalist programming, one-click automatic identification of trained components and solder joints, intelligent judgment of bad.

Solving the two traditional algorithm pain points:

- Long programming time.

- High false alarm rate.

1. SMT Inspection Solution

With the development of the smt chip processing industry, the function becomes stronger, and the precision of the mounted components is getting higher and higher, the volume is getting smaller and smaller, such as 01005, μBGA or PoP, the human visual inspection ability is far from enough, AOI replaces manual , with higher stability, repeatability and higher precision.

SMT AOI equipment, through real-time capture of board image, convolutional neural network algorithm is adopted to process the image, intelligent determination of components (missing parts, offset, turn over parts, wrong parts, reverse, etc.) and solder defects (tin, tin less, virtual welding, copper leakage, etc.)

For SMT Inspection two models can be choosed based on your capacity and budget: online and offline .

2. DIP Inspection Solution

Manual operation is prone to fatigue, unstable, difficult to control, and high cost. At the same time, with the improvement of manufacturing quality requirements, AOI instead of manual work has become the choice of more and more enterprises.

I.C.T DIP AOI captures board image in real time by high precision color industrial camera. Adopt Convolutional Neural Network (CNN) algorithm to process images. Judge defects of components intelligently to effectively control quality.

- DIP Online AOI AI-4026 (Before THT Soldering)

- DIP Inverted Camera Online AOI AI-4540 (After THT Soldering)

- DIP On-line Dual side AOI AI-5146W (After THT Soldering)

3. PCBA Coating Inspection Solution

PCBA circuit board conformal paint is widely used in high-tech fields, which can effectively achieve insulation, moisture-proof, leakage-proof, shock-proof, dust-proof, salt spray-proof and other protective effects, thereby improving the reliability of circuit boards and increasing their safety factor. And effectively delay the service life. Manual detection is difficult to achieve effective detection purposes, and there will be shortcomings such as poor stability, long test time, and inability to test the entire board.

- For conformal coating inspection

- Using UV light source to take pictures of the coating area and deep learning algorithm to effectively detect defects such as over-coating, under-coating, bubbles, foreign objects, etc.

X-Ray SMD Component Counting Machine

X-Ray SMD component Counting machine is also called X-ray SMT Counter, SMT Automatic X-ray counting machine, Intelligent SMT automatic Counter, Automatic X-ray counter etc.

Maintaining the correct materials and quantities is an important part of the SMT electronics manufacturing process. Usually, even among the highest SMT volume EMS electronics manufacturing service providers, sourcing and managing materials is a job that lacks core competence and is often overlooked.

X-Ray counting machine VS traditional mechanical counting is faster and more effective.

I.C.T X-Ray component counter is a device that applies AI algorithm to check various materials at high speed. It can be directly linked with the factory’s ERP/MES system and has a wide range of applications in warehouse management. Which can count a 7-15 inch tray in 8 seconds, or count three 7 inche trays at the same time, and can count 200 trays in less than 40 minutes. The accuracy up to 99.98~100%.

Implementation effect:

- Groundbreaking reduction in parts inventory management time

- Siginficant reduction in labor ( save labor cost )

- Minimize count error

- Productive utilization of manpower

- Direct linkage with factory ERP/ MES

I.C.T – Your Reliable Dearest Partner

For you we can provide Full SMT Solution, DIP Solution and Coating Solution with best quality and service.

More information about I.C.T please contact US at market@smt11.com