Precision in Motion: Exploring the I.C.T Solder Paste Jetting Machine for 5G Applications

Why Choose the Solder Paste Jetting Machine?

In today’s advancing technology landscape, the demand for smaller, denser electronic devices is rising. Manufacturers seek solutions like the solder paste jetting machine to meet these demands efficiently. These machines offer precision, automation, and quality control, essential for modern electronics production. With features like XY linear motor drive control and rapid customization platforms, the I.C.T-HD330 High-Precision Solder Paste Dispensing Machine from Japan sets new standards for efficiency and accuracy in soldering processes. From semiconductor packaging to LED backplanes, its versatility makes it invaluable across various industries. Backed by I.C.T’s commitment to excellence and exceptional service, clients can trust in both the equipment and support provided.

Meeting Diverse Manufacturing Needs with the Solder Paste Jetting Machine

The solder paste jet machine offers flexibility and precision, catering to diverse manufacturing needs. Its ability to customize platforms rapidly ensures optimal performance tailored to specific applications. Automatic needle height compensation and efficient image processing minimize errors, enhancing productivity and consistency. Features like non-contact laser detection and high-speed micro-spraying underscore its attention to detail and versatility in handling complex tasks. With precision solder paste printing capabilities, this machine excels across semiconductor packages, LED back-end assemblies, and more.

Advantages of the Solder Paste Jetting Machine Parameters

Minimum Dispensing Quantity:

The automatic solder paste jet printer machine excels in dispensing even the smallest quantities of solder paste, ensuring meticulous application for consistent results.

Dispensing Accuracy:

With exceptional accuracy reaching ±1 micron, the solder paste jetting machine guarantees precise and repeatable solder paste deposition, enhancing product quality.

Dispensing Speed:

Operating at a speed of 1500mm/sec, the machine offers swift and efficient dispensing without compromising accuracy, optimizing productivity.

Minimum Printable Dot Diameter:

Capable of printing dot diameters as small as 110 microns, the machine ensures intricate patterns and fine features with exceptional precision.

Image Processing Speed:

Its lightning-fast image processing speeds enable real-time detection and compensation for deviations, ensuring consistent dispensing accuracy.

Exploring the Solder Paste Jetting Machine’s Intriguing Features

Efficiency of the I.C.T-HD330

The solder paste jetting machine achieves dynamic positional accuracy within ±3 microns, ensuring uniform coating application and minimizing solder paste consumption.

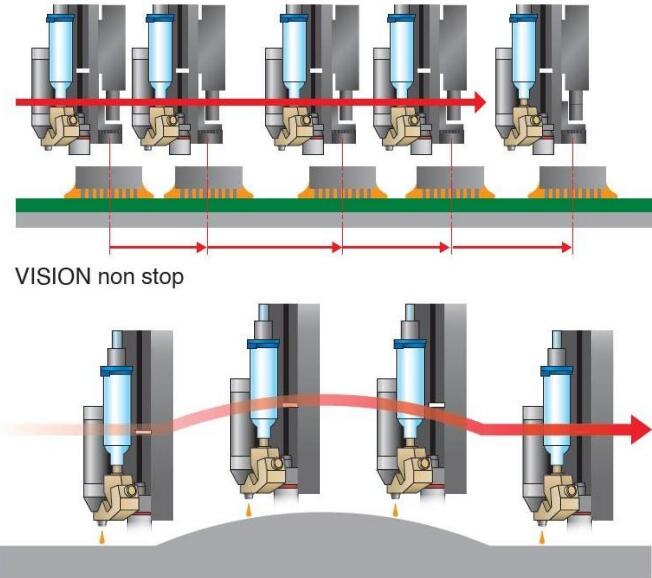

Height Compensation Mechanism in the I.C.T-HD330

Utilizing a laser height measurement system, the machine guarantees precise height compensation, enabling consistent solder paste deposition across diverse PCB surfaces.

Choosing Dispensing Volume in the Solder Paste Jetting Machine

Selection of dispensing volume considers factors such as component size, material, and dispensing requirements, ensuring optimal performance and avoiding over-dispensing.

Reducing Solder Paste Overlapping: Dual Compensation Mechanism

By automatically compensating for deviations in chip position and height, the machine minimizes solder paste overlapping, optimizing quality and minimizing waste.

Dual Compensation for Path and Volume: How Does the Solder Paste Jetting Machine Achieve It?

The machine achieves dual compensation for path and volume through automatic detection and adjustment mechanisms, ensuring precise solder paste deposition.

Detecting and Compensating for Chip Height Deviation

Advanced laser technology enables the machine to detect and compensate for chip height deviations, ensuring consistent dispensing accuracy.

Reliability of the Solder Paste Jetting Machine

Backed by high-precision linear motor drive control and automatic compensation features, the machine delivers reliable and consistent results in demanding production environments.

Enhancing Productivity with the Solder Paste Jetting Machine

With features like rapid customization, automatic compensation, and high-speed micro-spraying, the machine optimizes workflow and maximizes productivity while maintaining high dispensing accuracy.

Ensuring High-Precision Dispensing

Utilizing sophisticated techniques and efficient image processing, the machine guarantees precise solder paste deposition, enhancing product quality and reliability.

Reliable After-Sales Support for Your Solder Paste Jetting Machine

Manufactured in Japan, the solder paste jetting machine comes with professional technical support and training, ensuring proficient operation and maintenance. With comprehensive services and a steady supply of spare parts, clients can trust in I.C.T beyond the purchase.