How to Choosing the Right Wave Soldering Machine

Discover the key factors to consider when selecting a wave soldering machine for your manufacturing needs. Whether you want to learn about wave solder machine process, working, benefits or applications all information you are looking for is right here.

What is wave soldering Machine and its importance?

Wave soldering machine is a manufacturing process that is commonly used in the electronics industry to solder through-hole components onto printed circuit boards (PCBs). The process involves passing the PCB over a wave of molten solder, which wets the metal leads of the through-hole components and creates a permanent electrical connection.

In today’s society, electronic devices play an increasingly important role in our daily lives, and wave soldering is a crucial part of the manufacturing process for many of these devices. From smartphones and laptops to cars and medical equipment, electronics are everywhere, and wave soldering equipment is a key technology that enables their production.

Basic working principle of wave solder machine

Wave soldering machine is a process used in electronics manufacturing to attach components to a printed circuit board (PCB). The wave soldering equipment basic working principle of wave soldering involves applying a molten solder wave to the underside of a PCB, which passes over the leads of the components and creates a permanent solder joint. The PCB is first prepped for wave soldering machine by applying a flux, cleaning, and drying process. The PCB is then placed on a conveyor belt and moved over a wave of molten solder which is created by heating and maintaining a solder pot with molten solder. The wave of solder is carefully controlled to keep it at a consistent temperature and height to ensure that it creates a high-quality solder joint on every component.

1. Features of W series wave soldering

1.1 Operation and electrical control system

Touch screen wave soldering equipment is controlled by touch screen + PLC, easy to operate; the control panel is external, easy to adjust. It has intelligent fault diagnosis and can automatically record the equipment status and operations of different users.

The control system of the wave soldering equipment plays a role in comprehensively processing the information flow between the various positions and components of the wave soldering machine, coordinating and controlling the wave soldering process, and is an important factor affecting the system reliability and welding effect.

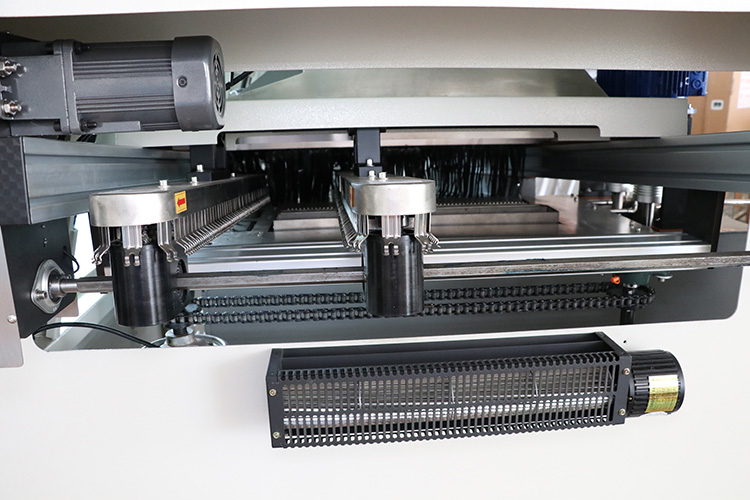

1.2 Wave soldering Machine Transportation system

In wave soldering machine, the function of the transportation system is to make the PCB enter and exit the wave soldering machine. The width of the guide rail can be flexibly adjusted according to the size of the PCB board (manual standard, automatic optional), and the inclination angle of the rail can be adjusted appropriately to ensure that the PCB enters the wave soldering machine smoothly.

W series wave soldering machine adopts double claws, good stability, not easy to deform, no shaking, no vibration, no sticking tin, titanium claw cleaning device is automatic cleaning, equipped with automatic pump and liquid storage tank, with industrial flexible brush, does not hurt titanium claws, clean Convenient and easy to operate.

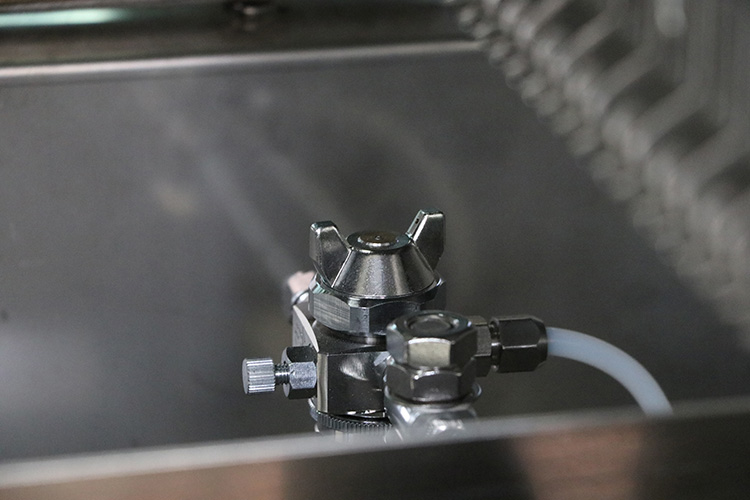

1.3 Spray system

The main function of the wave soldering machine spray system is to evenly spray the rosin flux on the PCBs. The quality of the spray system directly affects the soldering quality of the PCB.

The I.C.T wave soldering machine spray method performs PCB automatic detection induction spraying according to the speed and width of the PCB. Make the wetting range of the flux reach the best effect, adopt Japanese Kuroda Seiko nozzle, special drive control system, accurate and reliable. Various flow adjustments can be realized to make the atomization effect more uniform.

Stainless steel is used as a tray under the nozzle to hold waste water and flux, and it can be pulled out for cleaning at will.

The exhaust system is a labyrinth automatic recovery system, double-layer stainless steel wire mesh filter, which can filter and recover excess flux to the maximum extent.

1.4 Preheating system

The I.C.T wave soldering machine process uses hot air preheating and horizontal reflow soldering design. Each heating zone is not affected by adjacent heating zones, ensuring an accurate wave soldering machine temperature curve and effectively activating the flux to fully play its role. The preheating temperature is generally between 110℃ and 150℃, and the preheating time is between 1 minute and 3 minutes. Stable preheating temperature effectively prevents welding defects such as cold solder, bridging, and peak solder, reduces the thermal shock of the welding wave on the substrate, and effectively avoids problems such as warping, delamination, and deformation of the PCB during the soldering process. The soldering process.

I.C.T W2 series wave solder machine uses 2 bottom preheating zones, W3 uses 3 top and bottom preheating zones, and W4 uses 4 top and bottom preheating zones, which can meet the soldering requirements for various electronic products such as automotive electronics, communications, mobile phones, computers, and smart home appliances.

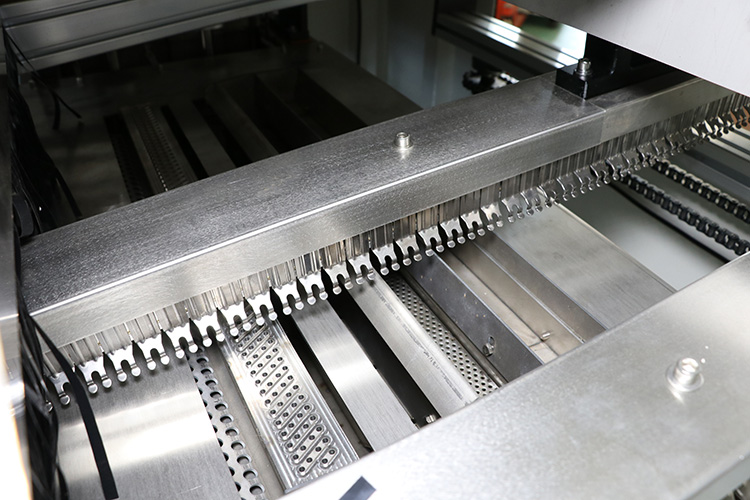

1.5 Soldering system

The wave soldering system of I.C.T, a wave soldering machine manufacturer, generally adopts double wave (economic wave). The advantage of using a double wave in the wave soldering machine is to reduce the production of bubbles and warping after soldering. The double wave technology preheats the substrate and components with a small wave before the wave soldering process, reduces vibration during the soldering process, and forms more stable and stronger solder joints after soldering. In addition, double wave technology can achieve higher soldering speed and shorter cycle time, thereby improving production efficiency and soldering reliability.

Solder pot is one of the wave soldering machine parts. Our wave soldering machine uses pure titanium material for the solder pot, which effectively prevents contamination and damage to the solder caused by impurities in the material of the solder pot. This is usually used for lead-free wave soldering. In terms of maintenance and upkeep of wave soldering later on, I.C.T’s solder pot is equipped with an automatic in and out function, which can be highly adjustable.

1.6 Cooling system

The wave soldering machine cooling system is mainly responsible for reducing the damage of thermal energy to the components and increasing the adhesive strength of the copper foil on the PCB substrate. If the temperature is too high, it can cause cracks and deformation in the solder joints, which will reduce the strength and reliability of the joints. Therefore, the role of the cooling system in wave soldering is very important. It can ensure that the welding area maintains an appropriate temperature, thus obtaining high-quality solder joints and reliable soldering results.

2.Optional function of wave soldering machine

2.1 Automatic Soldereing of guide rail

The automatic adjustment function of the guide rail is more flexible, which greatly saves the conversion time from one product to another, and product parameters information can be recorded. The guide rail is controlled by a stepping motor, which is precise and stable, and the front and rear are driven by synchronous gears to ensure that the width of the input of output the wave soldering track PCB is consistent.

2.2 Nitrogen protection device

Wave soldering machine nitrogen protection improves the quality of solder joints, reduces production costs, and reduces total costs; the application of nitrogen in electronic assembly processes can reduce defect rates and achieve higher reliability and lower costs. Nitrogen wave soldering machine at present, it is widely used in the field of electronics, especially in power supply, home appliances, communication, automatic control, medical treatment, military electronics and other fields.

2.3 Automatic tin adding device

It can automatically replenish and add tin to keep the liquid tin in the tin furnace at a certain height, and the production efficiency is greatly improved.

2.4 CBS (center board support) Device

I.C.T is a mature lead-free wave soldering machine manufacturer that we can supply center board support(CBS), stainless steel arc-shaped support bar, the support position and height can be quickly adjusted to prevent the circuit board from being overweight or panel deformation, and preventing the thin plate from being deformed due to high tin temperature.

3. Which wave soldering Machine is right for you

You can make a selection based on your own needs, or discuss and analyze with our professional SMT engineers to ensure that you choose a suitable wave soldering machine, which will not only save you costs but also improve production efficiency. and we also have selective wave soldering machine and high-end series Acrab wave soldering machine, for more information, please contact us immediately.

4. I.C.T technical support and after-sales service

Technical support

I.C.T overseas technical support engineers can go to your factory doing installation training services.

Also, I.C.T team provide online support with free cost.There are user manuals,installation videos coming with machine and in our server.

During 2019-2022, our engineer team provided full-line installation support to 50+ oversea customers by this way, and get very good feedback.

After-sales service

All I.C.T equipment enjoy 1- year warranty,during this period,any damaged parts will be provided for free.

We have a variety of after-sales service methods

One is online service. I.C.T engineers provide 7/24 uninterrupted service, and deal with most problems through online voice and video, and can also connect to your machine through remote collaboration software such as TeamViber and Todesk to check and deal with machine problems.

The second is on-site service. If necessary, we can also arrange engineers to go to the customer’s factory to provide support.

The third is local service. We have partner in your area, they can assist us to provide support for customers.

There are many ways for you to choose, we will provide the best support according to the actual situation and your demands, please rest assured.

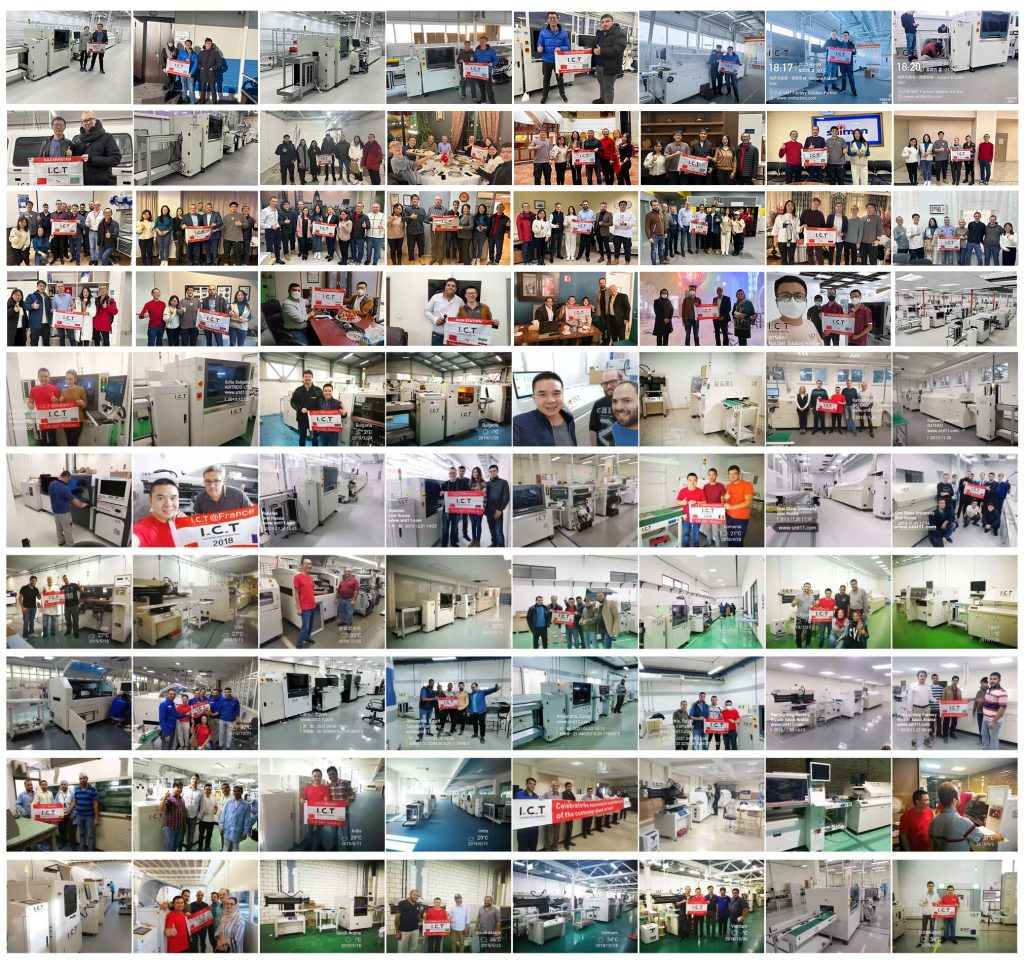

5. The following are photos of I.C.T customer factories

In case you want to learn more about wave soldering machine, contact us now.

I.C.T – Your Reliable Dearest Partner

For you we can provide Full SMT Solution, DIP Solution and PCBA Coating Solution with best quality and service.