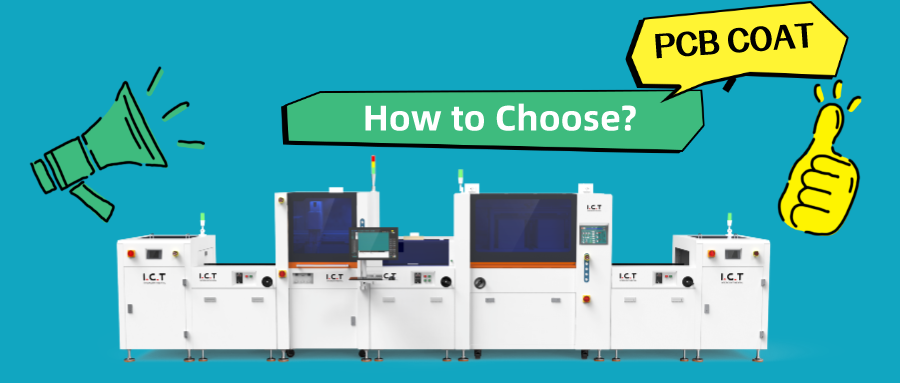

How do I choose a pcb coating machine line that’s right for me?

Choosing the right equipment for your PCB coating line can be a daunting task. To help you make an informed decision, we’ll walk you through the components of a standard PCB coating machine line and how they address common pain points. In this article, we’ll focus on the composition of the line, including the elevator, transfer station, coating machine, inspection station, curing oven, and their interconnectedness through a return conveyor. Let’s explore each element and understand its role.

Components of a PCB Coating Machine Line:

a. Elevator: The PCB coating line begins with an elevator, which efficiently transports the PCB boards to the next stage of the process.

b. Transfer Station: After the elevator, the boards are conveyed to a transfer station, where they are prepared for coating.

c. Coating Machine: The heart of the PCB coating line is the coating machine. We offer a variety of coating machines, including I.C.T-T550, I.C.T-T550U, I.C.T-T600, and I.C.T-T650.

d. Inspection Conveyor: Following the coating process, the boards move to an inspection station. The second transfer station is equipped with LED lights and a blue glass cover, allowing operators to inspect the coating quality closely. This feature is essential for ensuring that the coating is consistent and free from dust contamination.

e. Curing Oven: For UV-curable adhesives, we provide a UV curing oven to solidify the adhesive effectively.

f. Return Conveyor: Beneath the entire line runs a return conveyor, connected to the elevator. This conveyor system efficiently returns PCBs from the last elevator back to the first one, reducing the need for manual handling and streamlining the operation.

The Benefits of the PCB Coating Line Design:

The well-thought-out design of this PCB coating machine line offers several advantages:

- Easy Accessibility: The operator’s station is strategically located beside the coating machine, making it easy to access for setup and adjustments.

- Improved Efficiency: The integrated return conveyor eliminates the need for manual transport, optimizing the workflow.

- Quality Control: The inspection station with the blue glass cover allows operators to inspect coatings for quality and cleanliness.

- Dust Prevention: The blue glass cover also acts as a barrier to prevent dust contamination on freshly coated PCBs.

Learn More:

- If you want to explore the detailed specifications of our coating machines, check out our article on “Exploring Our PCB Coating Machine Models.“

- For insights into choosing the right coating valve for your adhesive, we have a dedicated article on “Selecting the Ideal Coating Valve.”

Visual Understanding:

To better comprehend how the elevator, transfer stations, and return conveyor work together, we have prepared a video demonstration. This will provide a clear and comprehensive overview of their operation.

If your PCBs are double-sided, I.C.T will give you a suitable and perfet SMT conformal coating line choice. Click the following link, to explore a dedicated solution designed for dual-sided PCBs. We’ve got your dual-sided needs covered, ensuring precision and excellence in every application. If you are also concerned about how to choose a curing oven, please click to learn how to choose an IR and UV curing oven

Compliance with European Safety Standards:

It’s crucial to mention that our PCB coating machine line adheres to the stringent European safety standards. We take quality and safety seriously, which is why each component in our production line is designed and manufactured to meet these standards. As a testament to our commitment to safety and quality, all our machines have earned the CE certification. This certification ensures that our equipment conforms to the European Union’s safety, health, and environmental protection requirements. When you choose our PCB coating machine line, you can trust in its safety and reliability, knowing that it aligns with international standards and regulations.

This additional paragraph emphasizes the commitment to safety and quality, providing reassurance to potential customers regarding compliance with CE certification and European safety standards.

Conclusion:

Choosing the right PCB coating machine line can significantly impact your production efficiency and the quality of your coated PCBs. Our comprehensive solution, consisting of an elevator, transfer stations, coating machines, inspection stations, curing ovens, and a return conveyor, is designed to address your needs and enhance your coating process. For further information on our machines and accessories, feel free to explore our related articles or contact I.C.T team for personalized guidance.