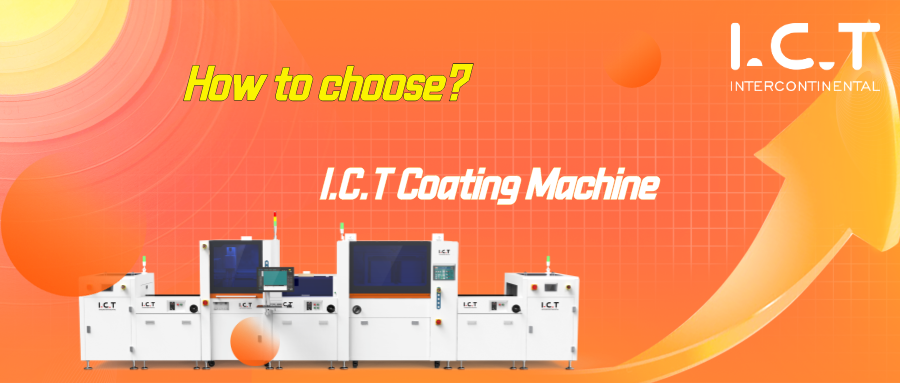

I.C.T PCB Conformal Coating Spray Machines: Choosing the Perfect Model for Your Needs

In the realm of PCB Conformal Coating Spray Machine, I.C.T offers a comprehensive range of advanced machines designed to cater to diverse production needs. Choosing the right machine can significantly impact the efficiency and precision of your conformal coating process. This article will delve into the intricacies of I.C.T’s PCB conformal coating spray machine models, including the I.C.T-T550, I.C.T-T550U, I.C.T-T600, and I.C.T-T650, while helping you make an informed decision that aligns with your specific requirements.

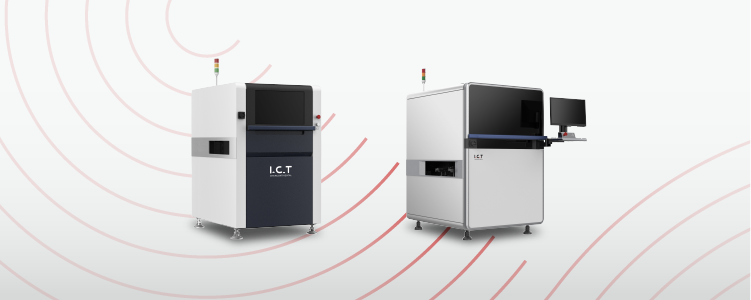

I.C.T PCB Conformal Coating Spray Machines

I.C.T is renowned for its commitment to innovation, quality, and safety, with all models holding CE certification. Let’s explore the key differences between these models and the factors to consider when selecting the ideal machine for your needs.

I.C.T-T550: Precision in Simplicity

- The I.C.T-T550 model is equipped with two crucial valves: the atomization valve and the precision valve.

- If you’re interested in exploring a variety of coating valves, simply click the link to discover more: Conformal Coating Valves

- It is an excellent choice for applications where fixed valves suffice, as it does not offer rotation or tilting capabilities.

- Perfect for straightforward conformal coating requirements, the I.C.T-T550 ensures consistent and reliable results.

I.C.T-T550U: Unleash Flexibility

- If you require more versatility, the I.C.T-T550U model is designed to meet your needs.

- The addition of a rotating U-axis empowers the valves to rotate a full 360 degrees and tilt up to 35 degrees, enabling precise coating in challenging, intricate areas.

- The I.C.T-T550U’s flexibility makes it an excellent choice for a wide range of applications.

I.C.T-T600: Doubling Efficiency

- The I.C.T-T600 closely resembles the I.C.T-T550 but boasts a unique feature – it is equipped with two atomization valves.

- This dual-valve setup enables you to coat two PCBs simultaneously, effectively doubling your production efficiency.

- Ideal for applications where speed and efficiency are paramount, the I.C.T-T600 streamlines the coating process.

I.C.T-T650: Versatility Redefined

- In cases where different valves are required to achieve comprehensive coating, the I.C.T-T650 is the solution.

- This model features two atomization valves and two precision valves, providing exceptional flexibility for diverse conformal coating applications.

- The I.C.T-T650 ensures precise and reliable results for even the most complex coating needs.

Conclusion PCB Conformal Coating Spray Machines

Selecting the right I.C.T PCB conformal coating spray machine is paramount for enhancing the efficiency and effectiveness of your production process. Consider factors such as the size, complexity, and coating requirements of your PCBAs. Rest assured, I.C.T’s unwavering commitment to innovation, quality, and safety guarantees that you’ll find the perfect solution to elevate your conformal coating endeavors. If you need further guidance or wish to tap into the expertise of I.C.T professional engineers for designing a customized coating production line, do not hesitate to reach out. We are here to help you achieve optimal results while meeting European safety standards.

If you’re uncertain whether your product requires a PCB dispensing machine or coating machine, feel free to reach out to us directly, or click here to read our comprehensive guide for further insights:Differences Between Coating & Dispensing