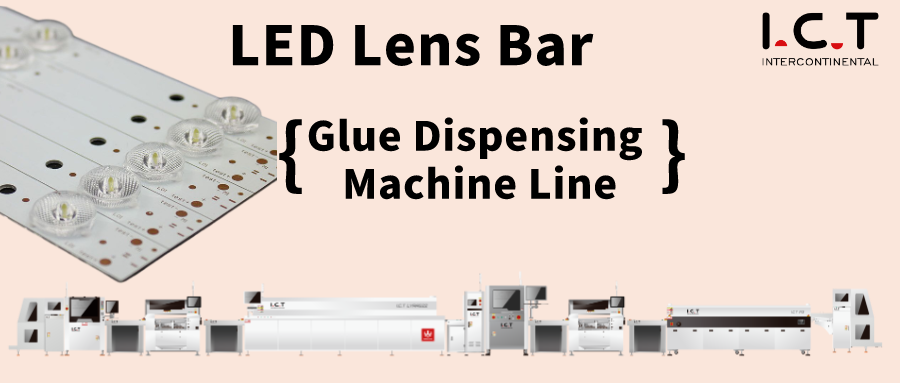

Optimize Your LED Lens Bar Production Line with a Glue Dispensing Machine Line

LED Lens bars, often used in various lighting applications, are essential components in modern technology. They serve as protective covers for LED lighting, enhancing light dispersion and ensuring efficient illumination. However, the manufacturing process can be complex and demanding, especially when it comes to assembling these delicate components. One key aspect that many manufacturers struggle with is the assembly line setup and efficiency. In this article, we’ll introduce a specialized solution, the Glue Dispensing Machine Line, which can streamline the glue dispensing machine line of LED Lens Bars.

The Components of the Production Line

To create an efficient LED Lens Bar assembly line, we recommend combining two essential production lines: the Surface Mount Technology (SMT) production line and the Glue Dispensing Machine Line.

SMT Production Line

The SMT production line consists of the following components:

- Board Loader

- Printer

- Conveyor

- Pick and Place Machine

- Conveyor

- Reflow Oven

- Buffer Conveyor

The SMT production line is responsible for mounting electronic components onto the printed circuit boards, including LED Lens Bars. After assembly, the completed LED boards move to the buffer conveyor, preparing them for the glue dispensing phase. For more information, click here for a detailed explanation: SMT Production Line Solution

Glue Dispensing Machine Line

The Glue Dispensing Machine Line comprises the following components:

- Glue Dispensing Machine

- Conveyor

- Pick and Place Machine

- Conveyor

- Curing Oven

- Unloader

This specialized line focuses on the glue application and assembly of the Lens Bars. Here’s a detailed breakdown of the process:

Buffer Conveyor from SMT

Once the LED boards reach this point, they are ready for the glue dispensing process.

Glue Dispensing

The Glue Dispensing Machine is designed to apply precise amounts of adhesive to the LED boards. It operates at a high speed, ensuring efficient and accurate glue placement. Typically, each Lens Bar requires three drops of adhesive.

Pick and Place Machine

A key component here is the Blue Light Camera, which ensures precise placement of the Lens Bars on the boards. For this purpose, you can choose specialized models such as the Decan L2 or Decan S1 from Hanwha’s series of pick and place machines. we also recommend considering JUKI RS-1R, which offers the option to add a special camera for precise Lens placement, making it another excellent choice for Lens Bar assembly.

IR Curing Oven

To solidify the adhesive, a curing oven with an Infrared (IR) heating system is used. This process typically involves temperatures of around 150 degrees Celsius, ensuring that the glue hardens and secures the Lens Bars in place.

PCB Unloader

Once the Lens Bars are securely attached, they move to the unloader, where they are ready for further processing.

Compliance with European Standards

Rest assured that all the equipment in our production line solutions complies with stringent European standards and proudly carries CE certification, guaranteeing both quality and safety.

Conclusion

At I.C.T, we offer professional LED Lens Bar production line design services to cater to your specific needs. With our specialized Glue Dispensing Machine Line and other advanced equipment, we are committed to enhancing the efficiency and quality of your LED Lens Bar production process. We also take pride in our exceptional post-sales support; you can find detailed information about it by clicking the link.

By optimizing your production line with the Glue Dispensing Machine Line, you can increase your manufacturing efficiency and ensure the high-quality production of LED Lens Bars. Don’t hesitate to reach out to I.C.T team for all your production line design and equipment needs.