Automatic Glue Dispenser Machine for PCB: I.C.T D600

In the ever-evolving landscape of electronic manufacturing, precision and efficiency are not just desirable but crucial. Enter the I.C.T-D600, an automatic glue dispenser machine designed to elevate production processes for a myriad of applications. From chip encapsulation to PCB assembly, SMT red-glue dispensing, LED lens production, and the creation of medical devices, the D600 from I.C.T is a versatile solution tailored to meet the demands of the industry.

Essential Attributes of the Automatic Glue Dispenser Machine

Compliance with European Safety Standards:

The Automatic Glue Dispenser Machine not only prioritizes efficiency but also safety, boasting compliance with European safety standards and holding a CE certificate. This ensures a secure and reliable manufacturing environment, aligning with global quality benchmarks.

International Component Quality:

Internationally renowned components are at the heart of the D600. From Panasonic servomotors to MINTRON CCD, each element is carefully selected, guaranteeing not only high performance but also durability. This commitment to quality components translates to a machine that operates seamlessly, reducing downtime and maintenance costs.

Impressive Performance Metrics:

The Automatic Glue Dispenser Machine D600 doesn’t just meet expectations; it surpasses them with exceptional performance metrics:

- Maximum Guide Rail Speed: 400mm/s

- Fastest Injection Valve Speed: 20 spots/sec

- Dispensing Accuracy: ±0.02mm

- Repeated Accuracy: ±0.01mm

Machine Characteristics:

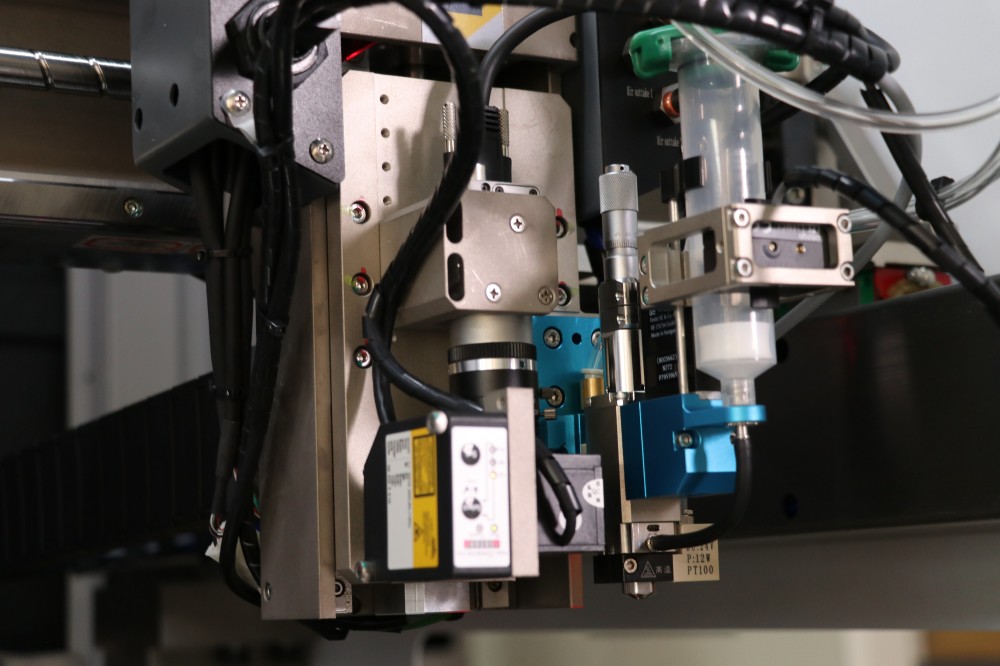

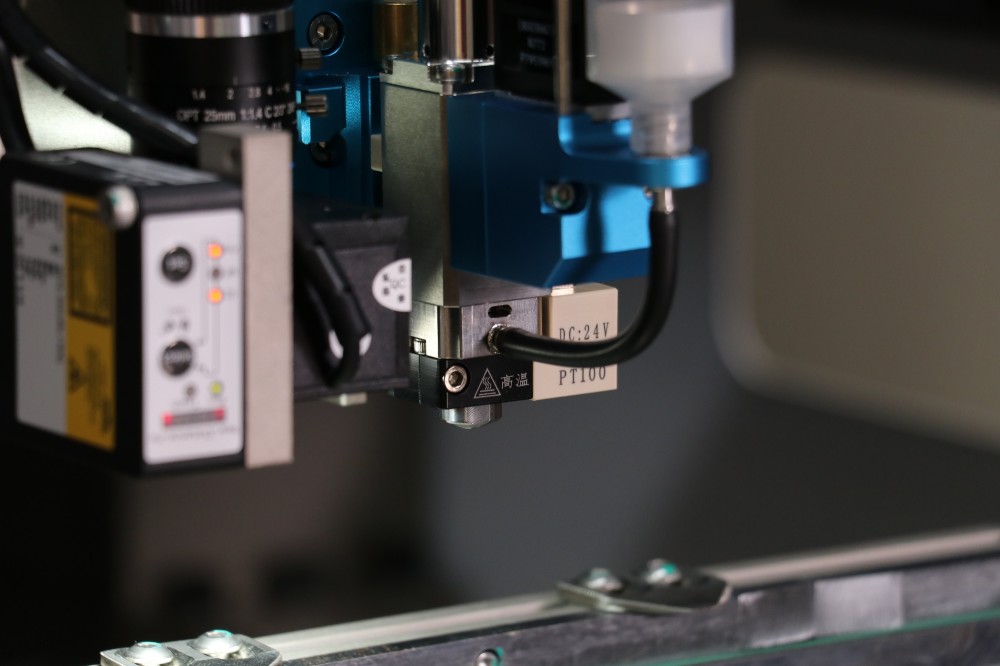

Core Part – Jet Valve:

- Non-contact jet dispensing method for high-speed operation (max jet speed: 20 spots/second).

- High accuracy with a minimum dispensing volume of 5nl, providing consistency compared to traditional methods.

- Flexibility and adaptability with extremely small dispensing volumes.

- Low maintenance cost and extended service life.

- Independent intellectual property rights.

- Thermostatic system for flow channel and sprayer ensures uniform glue temperature.

Enhanced Capacity:

- Non-contact jet dispensing eliminates the need for Z-axis motion.

- Integrated temperature control technology reduces manual intervention.

- Automatic glue compensation minimizes artificial regulation time.

- Dual-track design reduces waiting time.

- Automatic visual location identification and compensation.

- Non-contact height detection with laser reduces height detection time.

Flexibility:

- Capable of handling substrates or backings of various sizes.

- Optional heating module.

- Independent control of dual tracks with user-friendly software.

- Fast switching between different product lines.

- Universal platform suitable for various processes with different glues.

User Experience Highlights:

Streamlined Operation:

Users praise the Automatic Glue Dispenser Machine for its intuitive interface and user-friendly software. The machine’s dual-track design allows for independent control, making it easy to operate and facilitating quick switching between different product lines. This streamlines the production process, minimizing human error and enhancing overall efficiency.

Precision in Action:

Manufacturers appreciate the D600’s non-contact jet dispensing method, providing high-speed operation with impressive accuracy. The ability to achieve a minimum dispensing volume of 5nl ensures consistency in application, surpassing traditional dispensing methods. Users report a noticeable reduction in material wastage and improved precision in their end products.

Versatility and Adaptability:

The D600’s flexibility is a standout feature. It accommodates substrates or backings of various sizes, catering to the diverse requirements of manufacturers. The optional heating module further expands its capabilities, making it a reliable choice for different processes with varying glues.

Conclusion:

In conclusion, the I.C.T-D600 Automatic Glue Dispenser Machine isn’t just a piece of equipment; it’s a catalyst for enhanced manufacturing experiences. From its commitment to safety standards and quality components to its impressive performance metrics and user-friendly design, the D600 stands as a reliable and efficient solution. Manufacturers looking to optimize their production processes and elevate their output should consider the D600 as an invaluable asset. For personalized solutions and further inquiries, our dedicated engineering team is ready to assist you.

For more elevate performance with our dedicated care: Learn more about Service and Maintenance.Customize your setup for optimal results: Discover Options about Dispensing Line.Configurations. Seamless processes for a hassle-free experience: Explore Now Sales and Delivery.