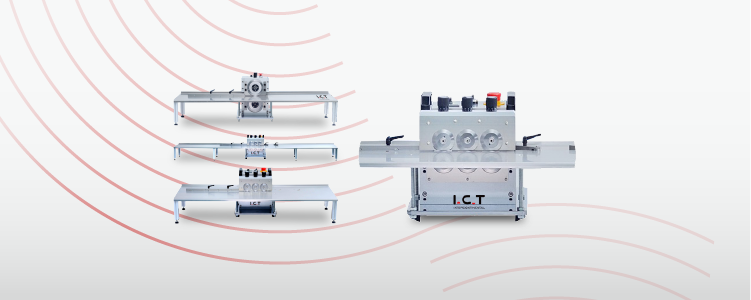

SMT Production with I.C.T’s Intelligence Auto Splicing Unit

Uninterrupted Efficiency in SMT Operations

In the dynamic landscape of SMT production, achieving uninterrupted efficiency is paramount. I.C.T introduces a groundbreaking solution – the Intelligence Auto Splicing Unit. This article explores how this innovation is reshaping the SMT industry.

Addressing Downtime Challenges

Solving Immediate Issues: The Intelligence Auto Splicing Unit is designed to eliminate downtime associated with material changes, a common hurdle in SMT factories. By enabling quick and seamless material splicing, it ensures continuous production without interruptions.

Maneuverability for Quick Response: The unit’s agile design allows operators to effortlessly navigate it to the precise location in need. Whether it’s a shortage on a specific pick-and-place machine or an urgent splicing requirement, the Intelligence Auto Splicing Unit responds swiftly.

Beyond Immediate Gains – Revolutionizing Hiring and Training

Challenges in Traditional Operations: Traditional SMT operations often rely on highly skilled operators, leading to production halts during staff transitions. Hiring and training new personnel becomes a substantial cost and time investment.

Automating Material Verification: The Intelligence Auto Splicing Unit addresses these challenges by automating material verification. It significantly reduces the learning curve for new operators, ensuring consistent production even with evolving staff.

For more details about specification:

Advantages at a Glance:

- Eliminating Production Disruptions: The Intelligence Auto Splicing Unit eradicates interruptions caused by material changes, ensuring a continuous production flow.

- Reducing Reliance on Highly Skilled Operators: With automated material verification, the need for highly skilled operators is diminished, allowing for more flexible staffing.

- Lowering Training Costs: The unit simplifies the training process, minimizing the time and resources required for onboarding new staff.

Unlocking Efficiency: Elevate Your SMT Operations with I.C.T

When contemplating the choice of both an Intelligent Auto Splicing Unit and an Intelligent Storage System, envision the power to effortlessly manage up to 10 SMT production lines simultaneously. I.C.T with its two decades of SMT expertise, becomes your strategic partner in enhancing efficiency and productivity.

Imagine the seamless coordination of an Intelligent Splicing Unit, ensuring uninterrupted material supply, coupled with the organizational prowess of an Intelligent Storage System streamlining the entire process. This dynamic duo not only oversees the harmony of your production lines but propels your efficiency to new heights.

At I.C.T, we don’t just offer equipment, we also craft SMT solutions. Our 20 years of SMT experience uniquely position us to understand and cater to your specific needs. Elevate your SMT operations with us – the architects of quality solutions. Feel free to reach out at any time to embark on a journey towards optimized efficiency and superior SMT performance.