Get the Wonders of SMD Tape Splicing Machine

In the dynamic world of Surface Mount Technology (SMT), I.C.T introduces a game-changing solution – the SMD tape Splicing Machine. Engineered to seamlessly integrate into your SMT auto production line, this innovative device ensures uninterrupted operation through rapid refueling without the need for shutdowns.

Unleash Efficiency with I.C.T’s SMD Tape Splicing Machine

The SMD Tape Splicing Machine, resembling a compact robotic assistant, stands poised to revolutionize your SMT production line. Powered by UPS without the need for a direct power source, it offers unparalleled flexibility—allowing you to effortlessly navigate it across your production floor. Its user-friendly operation makes it accessible to all; simply place the nearly depleted and new materials together on the pick-and-place machine, and let the splicing magic unfold.

Notably, this ingenious machine ensures seamless splicing, preventing any disruptions in your production line. Its coordination ensures a harmonious blend of materials, avoiding any discrepancies that might render your pick-and-place machine inoperable. Moreover, it possesses the capability to recognize material disparities during splicing, providing real-time alerts in the event of inconsistencies. In an industry where human errors are common, the SMD Tape Splicing Machine serves as an indispensable ally, offering precision and reliability.

For more details about specification:

Key Features:

- Non-Stop Production: I.C.T’s SMT Automatic Splicing Machine enables continuous production by swiftly refueling without disrupting the workflow.

- Precision Splicing: With an accuracy rate exceeding 98%, the machine precisely detects the position of empty components and seamlessly splices the head and tail of two rolls of material belts with identical specifications.

- Efficient Automation: Equipped with RC measurement functionality, the machine minimizes reliance on manual intervention, reducing management costs, enhancing detection efficiency, and boosting the overall production rate of your SMT production line.

- Error Prevention: Say goodbye to batch misfeeds. Our splicing machine ensures a smooth and error-free production process, preventing disruptions and enhancing the overall efficiency of your SMT line.

- Comprehensive Coverage: I.C.T’s SMT splicing machine provides full coverage for feeders ranging from 4mm to 72mm, catering to diverse production needs.

Why Choose I.C.T?

At I.C.T, we are committed to revolutionizing the SMT industry with cutting-edge solutions. Our SMD Tape Splicing Machine reflects our dedication to providing efficient, reliable, and technologically advanced products. Elevate your SMT production capabilities with I.C.T – Your Partner in Innovation.

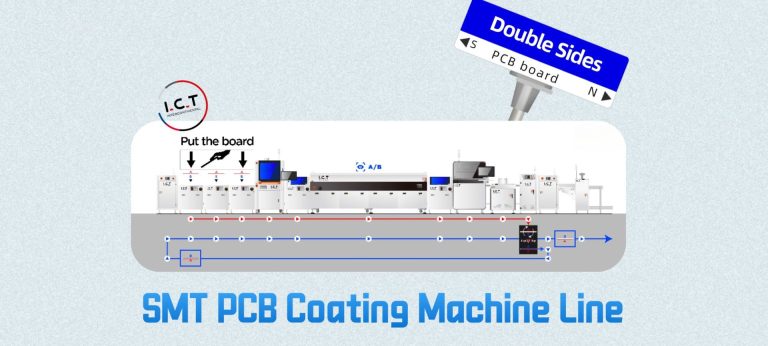

At I.C.T, we specialize in providing comprehensive SMT solutions, including pick and place machines, printers, reflow oven and wave soldering machines, insertion machines, AOI, and more. With 20 years of expertise, our equipment is trusted globally with clients in 75 countries, all backed by safety certifications like CE. Contact us for cutting-edge SMT technology and turnkey solutions.