One Article Explains Clearly the Differences Between I.C.T Screw Automatic Robot Models

Using a screw automatic robot can present various challenges or pain points during operation

- Complex Program Setup:

- Some screw machines might involve intricate program setups, posing a challenge for operators unfamiliar with programming.

- Adaptability Issues:

- Different screw specifications and sizes may require distinct settings, and certain screw machines might have limitations in terms of adaptability.

- Maintenance and Troubleshooting:

- Regular maintenance may be required for screw machines operating over extended periods, and troubleshooting might necessitate professional technical support, leading to production interruptions.

- High Costs:

- Advanced screw machine technologies can come with a higher price tag, which might be a challenge for small businesses or those with budget constraints.

- Operator Training:

- Operating screw machines may demand training to ensure operators are proficient in using and maintaining the equipment.

- Customization Requirements:

- For specific product specifications, screw machines may need customized screw heads and fixtures, adding complexity and costs.

Addressing these pain points depends on the specific model and manufacturer of the screw machine, and measures can be taken to resolve or alleviate these issues accordingly.

Precision, Efficiency, and Seamless Operation: Unveiling I.C.T’s Screw Automatic Robot

Embark on a new era of automated assembly with I.C.T’s advanced screw automatic robots, meticulously designed to elevate your production experience. For detailed insights into the usage scenarios and distinctive features of screw automatic robot, please click to explore further: Usage Scenarios Of Screw Robot Machine.

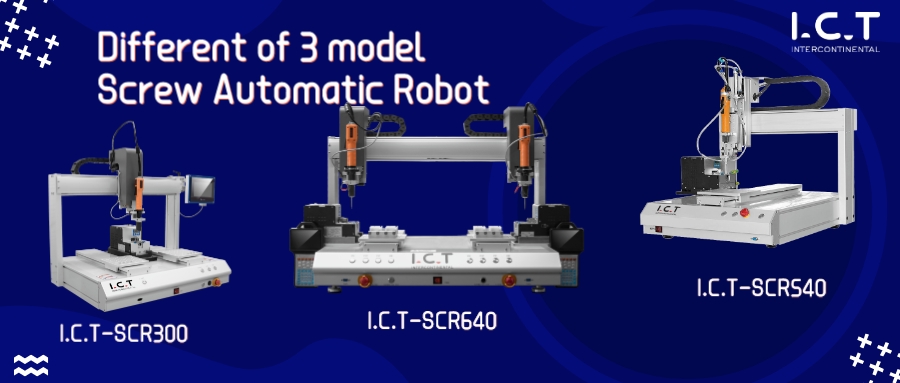

I.C.T-SCR300: Single Screw Head, Single Platform

- Versatility in Simplicity: Tailored for foundational screw tightening or loosening, the SCR300 ensures simplicity without compromising versatility.

- Secure Platform Design: The robust platform securely holds your PCB, offering stability for precise operations.

- Effortless Programming: With an intuitive programming controller, users can effortlessly set up programs, ensuring a swift integration into your production line.

I.C.T-SCR540: Single Screw Head, Dual Platforms

- Dual-Platform Dynamics: Elevate efficiency with dual platforms, facilitating simultaneous operations on one side while the operator installs the PCB on the other.

- Optimized Workflow: SCR540 optimizes workflow, minimizing downtime by seamlessly switching between platforms.

- Enhanced Adaptability: The system adapts to evolving production needs, providing flexibility for diverse assembly requirements.

I.C.T-SCR640: Dual Screw Heads, Dual Platforms

- Diversity in Action: Dual screw heads with distinct programs enable simultaneous production of diverse products.

- Configurability Redefined: Tailor configurations for left and right screw tightening, unlocking a new level of configurability for your production line.

- Precision in Parallel: SCR640 ensures precision in parallel operations, meeting the demands of complex assembly processes.

Programming I.C.T’s screw machines is an intuitive experience, requiring a mere 1-2 hours to master using the dedicated programming controller. Store up to 999 programs internally and effortlessly import programs using USB, ensuring a seamless integration into your workflow. Take advantage of our customization expertise – share your product details, and we’ll craft specialized screw heads and fixtures, perfectly aligned with your product specifications and screw sizes. Revolutionize your assembly process with I.C.T’s user-friendly, efficient screw automatic robots, offering not just automation, but a refined user experience for your production journey.

Ensuring Safety and Excellence in Automation: Trust I.C.T’s screw automatic robot with CE Certification

Rest assured that all our screw machines at I.C.T comply with stringent European safety standards and proudly carry the CE certification. Your safety is our priority, and our commitment to these industry-leading safety measures ensures that our equipment is not only efficient but also meets the highest safety benchmarks.

At I.C.T, we go beyond just providing screw automatic robot. We specialize in offering comprehensive solutions for both Surface Mount Technology (SMT) and DIP assembly line equipment. Whether you are initiating a new factory or upgrading an existing one, our dedicated team tailors complete production line solutions to meet your specific requirements.

I.C.T engineers, equipped with profound expertise, stand ready to provide exceptional service and support. Whether you prefer online or offline assistance, our team is committed to ensuring the seamless integration and optimal performance of your equipment.

For inquiries, equipment configurations, or guidance on factory establishment, feel free to consult with us. I.C.T welcomes the opportunity to contribute to the success and efficiency of your operations.