Unlocking Precision and Efficiency with I.C.T’s Screw Robot Machines

In the realm of automated manufacturing, the screw robot machine, often referred to as a “screw robot,” has emerged as a transformative technology. These machines streamline the process of screwing components together, achieving high efficiency and precision. Let’s delve into the world of screw robots and explore the distinct features of I.C.T’s offerings.

Understand the usage scenarios of screw robot machine

screw robot machine, or screw robot, are commonly employed in various manufacturing and assembly scenarios where the repetitive and precise insertion of screws into components is required. Some typical usage scenarios include:

- Electronics Assembly: screw robot machine are widely used in the assembly of electronic devices, such as smartphones, laptops, and other consumer electronics, where small screws need to be precisely inserted into intricate components.

- Automotive Manufacturing: In the automotive industry, screw robots play a crucial role in assembling different parts of vehicles, including interior components, electronic systems, and engine components.

- Appliance Production: The manufacturing of appliances like washing machines, refrigerators, and microwaves often involves the use of screw robot machine to efficiently and accurately assemble various parts.

- Medical Device Manufacturing: Precision is paramount in the production of medical devices. screw robot machine are employed to ensure the accurate assembly of components in medical equipment.

- Industrial Machinery Assembly: Large-scale machinery and equipment, such as industrial robots or production line machines, often require the use of screw robots during the assembly process to ensure reliability and consistency.

- Aerospace Manufacturing: In the aerospace industry, where stringent quality and precision standards are essential, screw robot machine are utilized to assemble components in the production of aircraft and spacecraft.

- Furniture Production: Screw robots are employed in the assembly of furniture, providing efficiency and accuracy in joining various components.

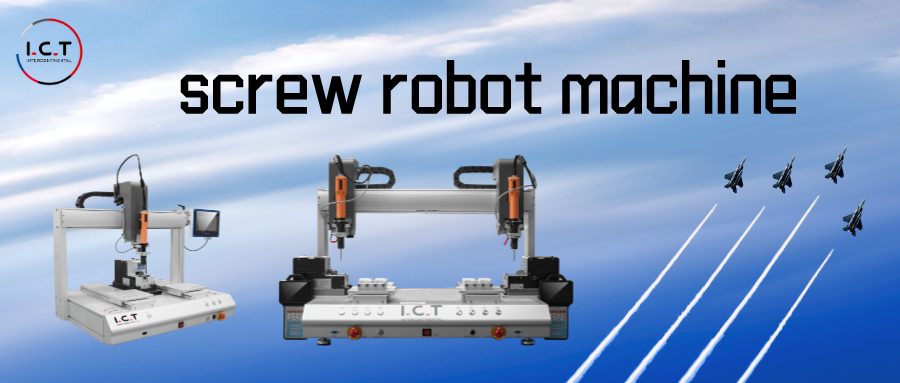

I.C.T’s Screw Robot Machine: Precision Tailored to Your Needs:

I.C.T offers a range of screw robot machines, each catering to specific requirements:

- I.C.T-SCR300: Designed with a singular screwdriver head and operating platform.

- I.C.T-SCR540: Equipped with single screwdriver heads and a dual operating platform.

- I.C.T-SCR640: Features a dual screwdriver head and dual operating platforms.

Each model corresponds to different configurations of screwdriver heads and platforms, providing flexibility for various assembly needs. To explore specific models and differences in screw machine selection, please click for more information: Differences Between I.C.T Screw Automatic Robot Models.

Customization for Unique Requirements:

Since your products are different, you cannot use the same fixture for different products, so our suggestion is that you can send us your product, and we will give you a fixture plan within 2-3 days. If you are satisfied, we can give you a quotation directly. To inquire, please click Contact Us.

Key Features of I.C.T screw robot machine:

- Cost Saving: Achieve high-efficiency operation with just one person, equivalent to the efficiency of 3-5 individuals.

- High Efficiency: Customize the number of electric screwdrivers for the Z-axis, allowing several screwdrivers to operate simultaneously.

- Precision Control: Quality step motors control the X, Y, and Z axes, ensuring smooth and precise machine operation.

- User-Friendly Operation: Utilize the Windows 7 English operating system, touchscreen interface, and wireless controller for easy programming.

- Advanced Software: Employ I.C.T’s self-developed software for fool-style programming, making parameter setting a breeze.

- Worker Efficiency: One operator can manage 2-3 robots, with the primary task being picking and placing fixtures.

- Strict Customization: Robots are meticulously customized based on product requirements, aligning seamlessly with production line demands.

Quality Assurance and CE Certification:

Rest assured that our range of screw robot machine at I.C.T adheres to the rigorous safety standards set by Europe and holds the esteemed CE certification. Your safety is paramount to us, and our commitment to compliance ensures that you can confidently use our equipment.

Comprehensive SMT Solutions and Expert Support:

I.C.T proudly offers a diverse array of SMT assembly line equipment. Whether you’re establishing a new factory or upgrading an existing one, we customize equipment configurations to meet your unique needs. Our dedicated team of engineers stands ready to provide exceptional service and support, available both online and offline. For inquiries, equipment configuration, or assistance in setting up your factory, feel free to consult with us. Your success is our priority, and we look forward to contributing to the efficiency and triumph of your operations.