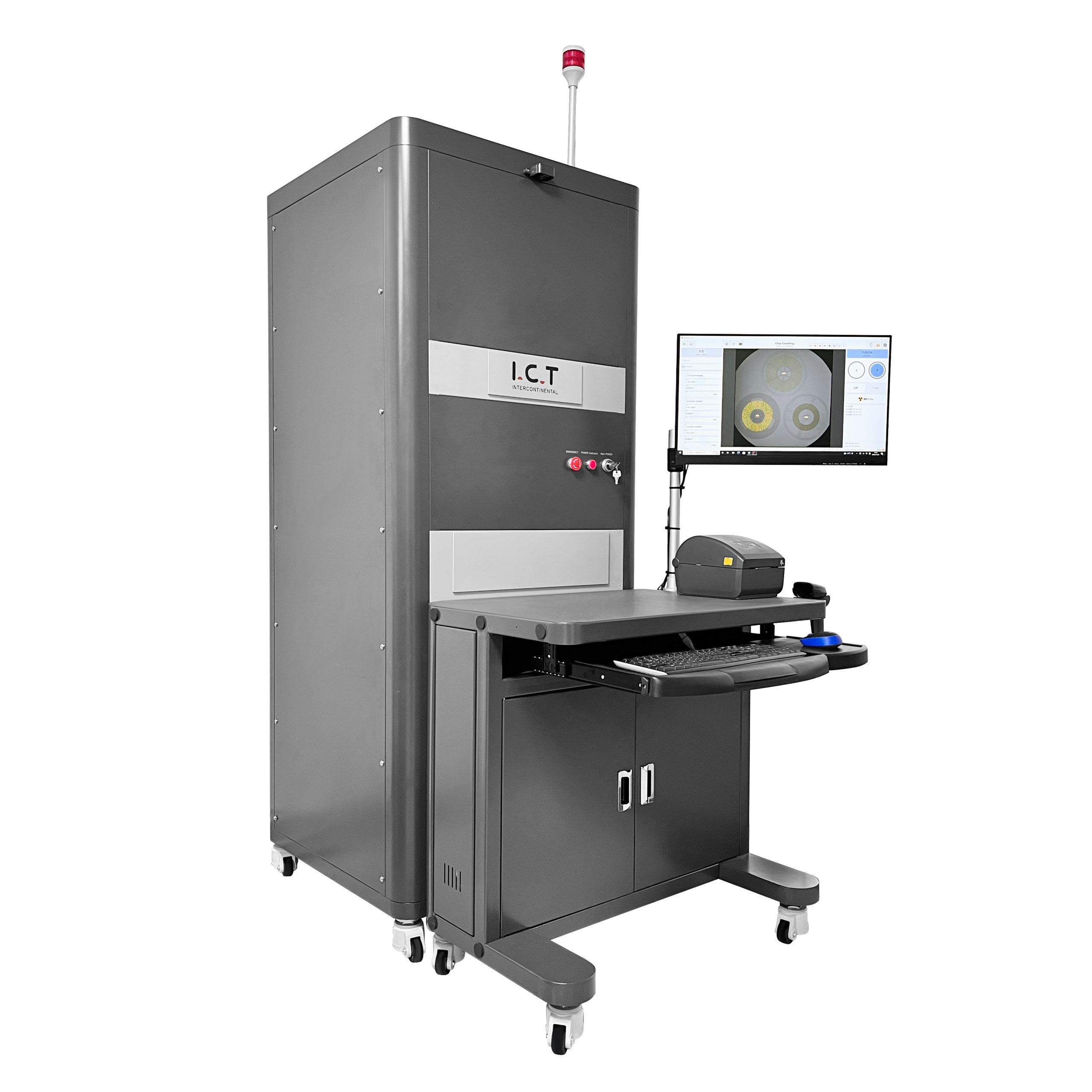

Automatic Feeder Tape Splicing Machine I.C.T-AISM08

- Efficient and Reliable Splicing: Achieves over 98% splicing accuracy, preventing production line stoppages caused by manual errors.

- Simple Operation: Easy to learn in just 5 minutes, allowing general workers to operate, reducing the need for highly skilled personnel.

- CCD Optical Detection: Automatically detects and calibrates components, ensuring precise cutting and splicing, minimizing material waste.

- Enhanced Production Efficiency: Increases SMT production line efficiency by more than 95%, reducing downtime and maximizing output.

Description

I.C.T-AISM08 | Automatic Feeder Tape Splicing Machine

Maximize Production Efficiency with Reliable Splicing

The I.C.T Automatic Feeder Tape Splicing Machine, model I.C.T-AISM08, is specifically designed to meet the stringent demands of modern SMT production lines, allowing for fast refueling without the need for a shutdown. This intelligent machine not only detects empty components and performs precise cutting but also boasts a splicing accuracy of over 98% for consistent results across material reels of the same specification.

Why Choose I.C.T-AISM08?

In any production environment, the last thing you want is a line stoppage, especially due to incorrect material splicing. Such disruptions can significantly impact your production schedule and delay shipments, costing both time and money. While human errors are inevitable, the I.C.T-AISM08 ensures flawless splicing, eliminating the risk of mistakes that could lead to costly downtime.

Moreover, this machine drastically reduces the need for highly skilled operators. With simple training that takes just 5 minutes, a general worker can manage the machine, freeing up your resources from extensive and expensive talent development. This means you can maintain high production standards without relying on specialized personnel.

Key Features:

- Simple Operation: The Automatic Feeder Tape Splicing Machine is user-friendly, with an easy learning curve that allows any operator to master its functions in just 5 minutes, reducing the need for skilled labor.

- Error Proofing: Automatic code scanning and error-proofing mechanisms work in tandem with your MES system, providing double protection against misfeeds and ensuring production accuracy.

- CCD Empty Component Detection: Advanced CCD optics detect and identify even the smallest components, such as 01005, ensuring precise handling and avoiding production errors.

- Accurate Traceability: Seamless MES integration enables precise traceability, giving you full control and visibility over your production process.

- Increased Production Rate: The I.C.T-AISM08 boosts your SMT line’s production rate by over 95%, ensuring that your production keeps pace with demand and reduces downtime.

- Measured Value Determination: The optional RC measurement function prevents batch misfeeds, ensuring that only the correct components are spliced.

- Labor Efficiency: With one person able to operate two SMT lines, the I.C.T-AISM08 significantly reduces labor costs and improves overall efficiency.

- Precise Splicing: Automatic calibration and accurate cutting ensure perfect splicing every time, reducing material waste and enhancing production consistency.

- Efficient Recycling: After splicing, the machine’s automated material collection feature allows for quick and convenient reel recycling, minimizing downtime and maximizing productivity.

- Fast Operation: Complete the entire splicing process in just about 10 seconds, keeping your production line running smoothly without unnecessary interruptions.

The Value of Investment

Investing in the Automatic Feeder Tape Splicing Machine is more than just purchasing a machine—it’s securing the reliability of your production line. By eliminating the risks associated with manual splicing errors, you ensure consistent production output, timely shipments, and reduced operational costs. This machine not only enhances your production efficiency but also provides peace of mind, knowing that your line won’t suffer from preventable stoppages.

Enhancing SMT Assembly Efficiency: Essential Equipment and Expert Support

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.

Additional information

| Model | I.C.T-ASM08 |

|---|---|

| Dimensions | 550*470*1300 |

| Weight | Approx: 65KG |

| Applicable Mounter | Full SMT brand |

| Splicing Mode | Auto cutting and Splicing |

| Splicing Tape Size | 32mm |

| Splicing Tape Package | Reel |

| Splicing Cycle Time | 6-12sec |

| Passing rate on Mounter | 95% |