How I.C.T SMT Production Line Support Aerospace and Automotive Projects

In October 2024, a valued European client received their full suite of SMT and DIP production lines from I.C.T. These systems are now set up in their factory, with the SMT equipment arranged into a seamless SMT production line and the DIP system set up alongside. What makes this project particularly exciting? It’s the client’s partnership with a leading aerospace company, which spans decades. This time, the client is expanding their service offering, tapping into a new project that will serve the local automotive industry. With I.C.T’s advanced production technology, this project is poised to deliver high-quality electronic components and accessories for automotive companies.

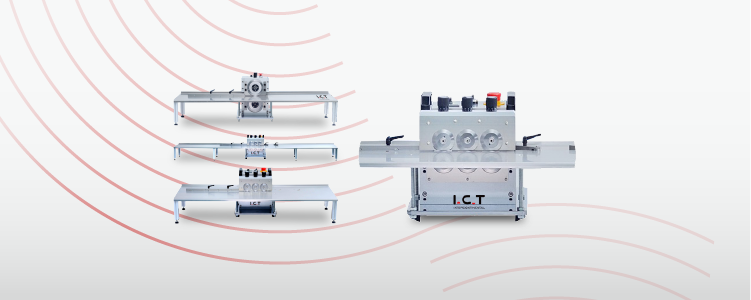

A Perfect Fit for High-End Automotive Production

The customer’s decision to invest in I.C.T’s high-end SMT production line speaks volumes about their commitment to quality. This isn’t just any assembly line. Alongside the essential components like the printer, pick-and-place machine, and reflow soldering oven, I.C.T. has also provided SPI (Solder Paste Inspection) and AOI (Automated Optical Inspection) equipment. Why are these essential? Because in the highly competitive world of electronics manufacturing, especially when the end product serves industries like aerospace and automotive, consistency is key.

By integrating SPI and AOI into the production process, the client ensures that every product passing through the line is inspected for potential flaws. Any issues, no matter how minor, are flagged immediately, ensuring an incredibly high yield rate. No more worrying about unseen defects causing trouble down the line – the inspections happen in real time, minimizing human error and maximizing the quality of each and every part.

DIP Line Designed for Precision and Performance

On the other side of the production floor, the client’s DIP line also stands out as a key player in this high-end setup. They’ve opted for a JUKI odd-form component placement machine and selective wave soldering machine, both known for their precision. These choices reflect the client’s ambition to work with the most demanding, high-end projects that require flawless assembly. Why is selective wave soldering a great machine? The answer lies in the improved yield rate it offers compared to traditional wave soldering. Selective soldering allows for more controlled application of solder, reducing the likelihood of defects and ensuring each connection is as reliable as possible. For automotive electronics, where safety and reliability are paramount, this is crucial.

Behind the Scenes: Our Expert Engineers Tony and Roka

One of the true standouts of this project has been the dedication and expertise of our engineers, Tony and Roka. While they may be young, their wealth of experience in setting up, configuring, and troubleshooting SMT Production Line and DIP systems has proven invaluable. They’ve worked tirelessly to ensure that everything is running smoothly for the client. After just under a month of installation, the customer’s own engineers are now fully trained and capable of running the production line with minimal assistance. From routine troubleshooting to advanced problem-solving, the client is now self-sufficient.

As Tony puts it, “It’s incredibly rewarding to see our systems in action, especially when we know how much they can help a client meet their production goals. The challenge is always to ensure smooth integration, and in this case, seeing everything come together in such a short period has been a fantastic experience.”

Building Long-Term Partnerships with Trust and Quality

At I.C.T, we understand that success in this industry isn’t just about providing top-tier equipment; it’s about building relationships that last. Our client’s aerospace connection spans decades, and we are proud to have earned their trust through years of providing reliable, high-quality machines that never compromise on performance.

Looking ahead, the success of this new automotive project is just the beginning. With our state-of-the-art SMT and DIP lines, the client is ready to produce electronic components that meet the strictest standards in the aerospace and automotive industries. With I.C.T’s continuous support and the customer’s in-house expertise, we’re confident that the future is bright.

The Final Word: Why Quality Matters

When it comes to industries like aerospace and automotive, the stakes couldn’t be higher. One tiny defect in a component can lead to catastrophic results. That’s why every detail of the production line has been meticulously designed for the highest possible quality. Whether it’s the precision of the JUKI odd-form machine, the accuracy of selective wave soldering, or the real-time inspections from SPI and AOI, I.C.T. is committed to giving our clients the tools they need to succeed.

To our valued client: we are thrilled to be part of your journey and can’t wait to see what you’ll achieve with this new production line.