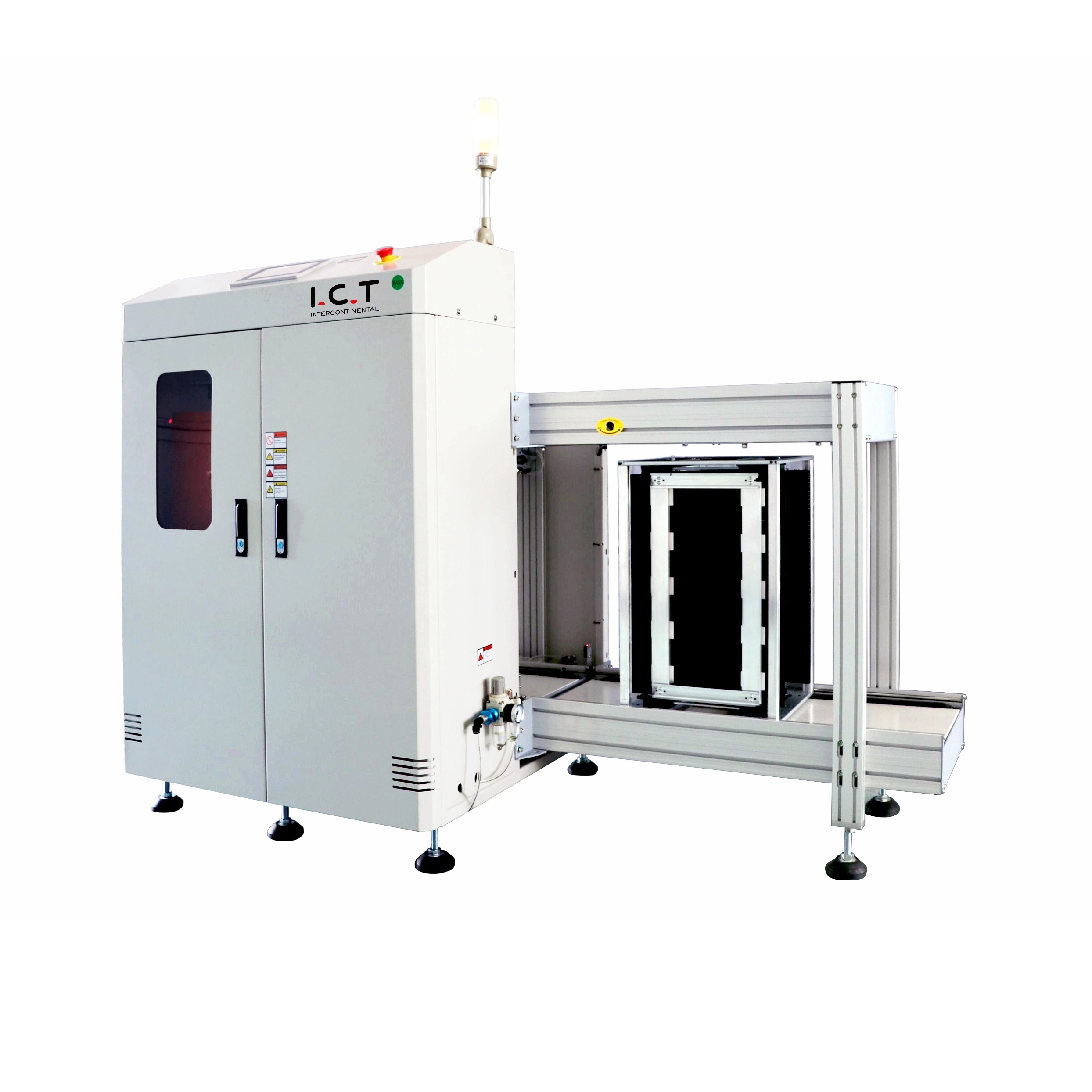

I.C.T-DUL-M | PCB Dual-rails SMT Unloader

Elevate SMT productivity with our Dual-rails SMT Unloader. Robust design, user-friendly controls, and seamless integration for optimal performance.

Loader&Unloader Series | Conveyor Series

Buffer Stacker Series | Traffic Controller Series

Description

I.C.T-DUL-M | PCB Dual-rails SMT Unloader

Optimize your SMT production line with our advanced Dual-rails SMT Unloader. Engineered for efficiency, its robust design ensures stability and reliability. Seamlessly navigate operations with touch screen and PLC controls, enhancing user-friendly experience.

Secure magazine racks with top & bottom pneumatic clamps, guaranteeing stability during unloading. The special gas circuit design eliminates PCB breakage concerns, ensuring a smooth workflow. Swiftly identify and resolve issues with the automatic fault code display function, minimizing downtime.

Equipped with wear-resistant cables, our Dual-rails SMT Unloader ensures a long service life for consistent performance. Seamlessly integrate with other equipment using the compatible SMEMA interface, fostering efficient communication in your production line.

Key Features of Dual-rails SMT Unloader

- Sturdy Construction: Features a robust, firm, and stable design for reliable performance.

- User-Friendly Operation: Seamlessly control operations with touch screen and PLC, enhancing ease of use.

- Magazine Security: Utilizes top & bottom pneumatic clamps to secure the magazine rack, ensuring stability.

- Breakage-Free Guarantee: Our special gas circuit design ensures a flawless operation, guaranteeing no PCB breakage.

- Intelligent Fault Diagnosis: Swiftly identify issues with the automatic fault code display function, minimizing downtime.

- Durable Performance: Equipped with wear-resistant cables for a prolonged service life, ensuring consistent reliability.

- Seamless Connectivity: Features a compatible SMEMA interface, promoting smooth integration into diverse manufacturing scenarios.

Applications: Designed for high-efficiency SMT production lines, the Dual-rails SMT Unloader excels in scenarios requiring precision and reliability. From consumer electronics to automotive industries, this unloader adapts seamlessly to various manufacturing setups, optimizing workflow and minimizing disruptions. Elevate your production efficiency with this cutting-edge solution.

Specification of Dual-rails SMT Unloader

PCB Size(mm): 50*50-530*460

Rack Size(mm) 355*320*563 – 535*530*570

Time Feed PCB: Seconds 6 Approx.

Indexing Pitch: 10.20.30.40mm or Specify

Control System: PLC

Power: Max 300 VA

Air Supply: 4-6bar, 10ltr/Min

Communication: SMEMA for Both In & Out

Power Supply: 1 PH AC 220V 50/60Hz (Option: 110V to 380V)

Loader – Dimension(mm): 1800*1435*1250- 2330*1950*1250

Please Contact Us directly for more specifications of the Dual-rails SMT Unloader

Enhancing SMT Assembly Efficiency: Essential Equipment and Expert Support

Additional information

| Time Feed PCB | Seconds 6 Approx. or Specify |

|---|---|

| Indexing Pitch | 10.20.30.40mm or Specify |

| Control System | PLC |

| Power | Max 300 VA |

| Air Supply | 4-6bar, 10ltr/Min Max |

| Transport Height | 900±20mm(or Customer Specified) |

| PCB Direction | L to R or R to L |

| Communication | SMEMA for Both In & Out |

| Power Supply | 1 PH AC 220V 50/60Hz (Option:110V to 380V) |