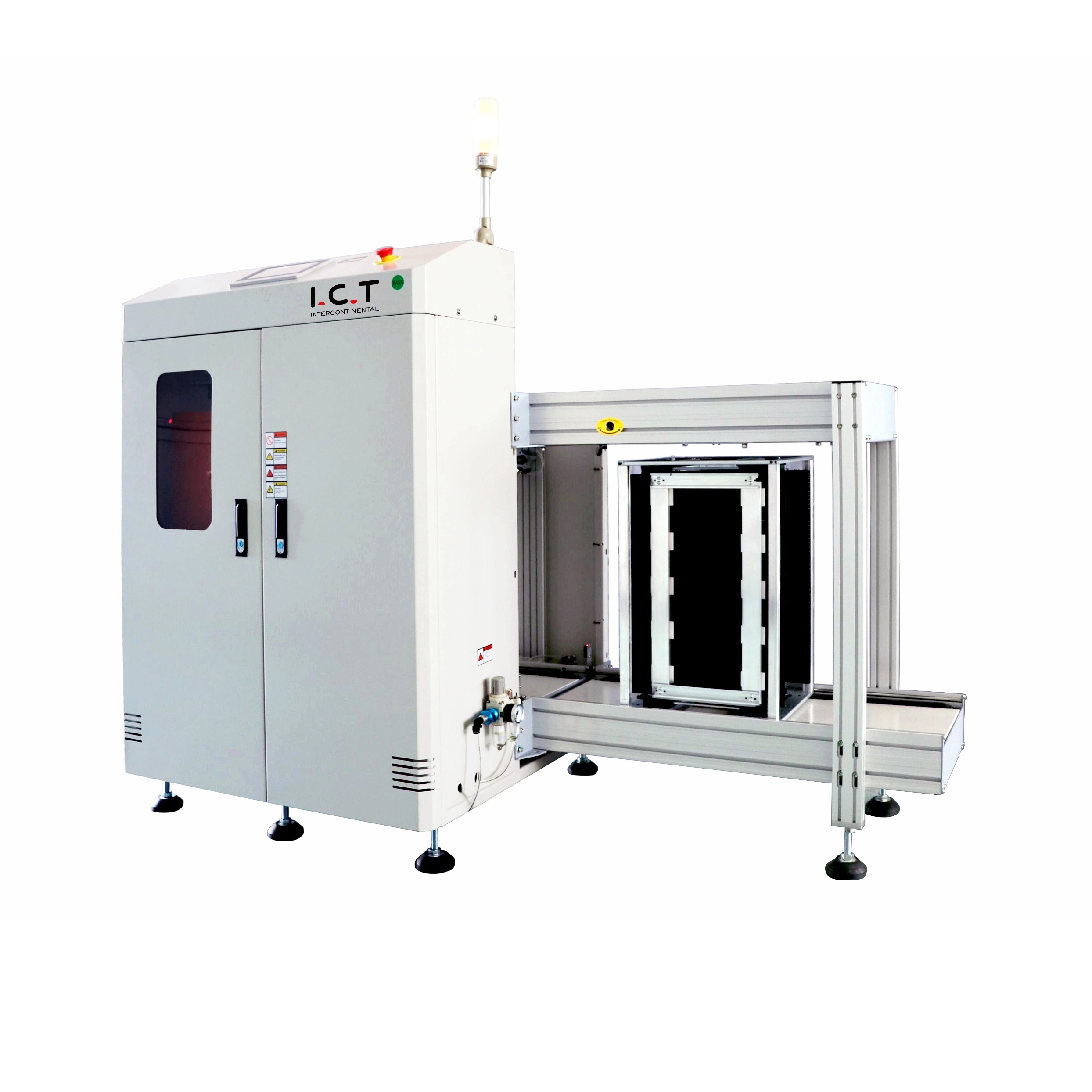

I.C.T-LD-L | PCB Magazine SMT Loader Unloader

Maximize SMT efficiency with our precision SMT Loader Unloader. Streamlined for seamless production, ensuring reliability and speed.

Loader&Unloader Series | Conveyor Series

Buffer Stacker Series | Traffic Controller Series

Description

I.C.T-LD-L | PCB Magazine SMT Loader Unloader

Elevate your SMT production with our cutting-edge SMT Loader Unloader. Engineered for seamless integration, it guarantees a streamlined workflow. Whether loading or unloading, experience precision and speed with our innovative solution. Our SMT Loader Unloader is designed for optimal efficiency, meeting high-volume production demands. Invest in the future of SMT technology, transforming your production line with reliability and precision. Upgrade to our SMT Loader Unloader for a smarter, more efficient manufacturing experience that ensures top-notch performance every step of the way.

Key Features of SMT Loader Unloader

- Robust Stability: Boasting a sturdy, firm, and stable design that ensures reliability in diverse manufacturing environments.

- User-Friendly Control: Enjoy effortless operation with a touch screen and PLC control system, putting advanced technology at your fingertips.

- Magazine Security: Achieve optimal magazine rack handling with top & bottom pneumatic clamps, providing a secure and stable platform for your SMT operation.

- Breakage-Free Assurance: Experience peace of mind with our special gas circuit design, guaranteeing no PCB breakage during the loading process.

- Fault Code Diagnosing: Effortless troubleshooting with automatic fault code display function, allowing quick identification and resolution of issues.

- Durable Performance: Benefit from a long service life with wear-resistant cables, ensuring consistent and reliable performance over time.

- Seamless Connectivity: Enhance your workflow with compatibility through the SMEMA interface, facilitating easy integration with other equipment.

Upgrade your SMT process with our advanced SMT Loader Unloader – a perfect blend of stability, efficiency, and user-friendly features designed to elevate your manufacturing experience!

Specification of SMT Loader Unloader

Loader/ Unloader – PCB Size(mm): 50*50-620*460

Loader/ Unloader – Rack Size(mm) 355*320*563 – 630*530*570

Time Feed PCB: Seconds 6 Approx.

Indexing Pitch: 10.20.30.40mm or Specify

Control System: PLC

Power: Max 300 VA

Air Supply: 4-6bar, 10ltr/Min

Communication: SMEMA for Both In & Out

Power Supply: 1 PH AC 220V 50/60Hz (Option: 110V to 380V)

Loader – Dimension(mm): 1330*765*1250 – 2065*1230*1250

Unloader – Dimension(mm): 1730*765*1250 – 2610*1230*1250

Please Contact Us directly for more specifications of the SMT Loader Unloader

Enhancing SMT Assembly Efficiency: Essential Equipment and Expert Support

Additional information

| Time Feed PCB | Seconds 6 Approx. or Specify |

|---|---|

| Indexing Pitch | 10.20.30.40mm or Specify |

| Control System | PLC |

| Power | Max 300 VA |

| Air Supply | 4-6bar, 10ltr/Min Max |

| Transport Height | 900±20mm(or Customer Specified) |

| PCB Direction | L to R or R to L |

| Communication | SMEMA for Both In & Out |

| Power Supply | 1 PH AC 220V 50/60Hz (Option:110V to 380V) |