Understanding the Crucial Role of Dust Collectors in PCB Depaneling Machines

In the realm of PCB manufacturing, precision is paramount, but it goes hand in hand with cleanliness. Dust and debris can wreak havoc on the delicate electronics. This article delves into the significance of dust collectors, how they work, and which PCB depaneling machines require them.

The Dust Collector’s Crucial Function

Dust collectors, often referred to as dust extractors, are indispensable in PCB manufacturing. When a PCB depaneling machine or a Laser PCB Depaneling machine goes to work, they generate a substantial amount of dust. It’s at this moment that the dust collector springs into action. It employs a vacuum motor to suction the fine particles off the PCB and into the collector, where a filtration system captures the dust.

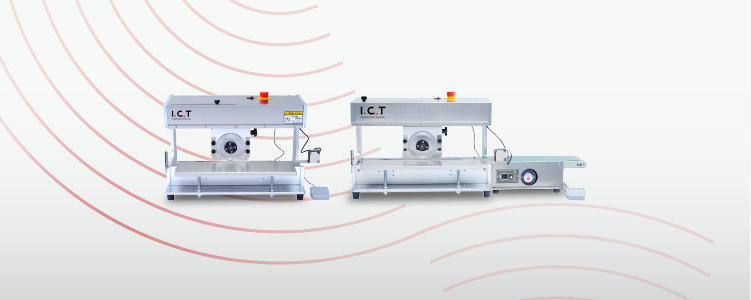

Which models of PCB depanelers require Dust Collector?

Several PCB depaneling machines require the accompaniment of dust collectors to maintain precision and cleanliness. These machines include:

I.C.T-5700: Offline Depaneling Machine, high precision, very easy manual operation, dual platform, high efficiency.

I.C.T-IR350: In-line depaneling machine, high precision, very fast, can be placed in the back of the SMT production line, allowing you to realize Industry 4.0, AI automated production

I.C.T-LCO350:Through the laser cutting, so that your cutting accuracy can reach 0.002 one time, if you have requirements for your cutting accuracy, you can choose this

I.C.T-100A:For desktop PCB depaneling machines like the I.C.T-100A, compact size doesn’t mean a lack of precision. These machines are ideal for smaller-scale operations but still benefit from dust collectors to maintain clean operations.

The Science Behind PCB Dust Collectors

When a PCB depaneling machine goes to work, it often generates a significant amount of dust and debris. To prevent these particles from becoming charged and adhering to the PCBs, the machines are equipped with ionizing guns. These devices emit ions that neutralize the static charge on dust particles, rendering them less likely to stick to the freshly cut PCBs.

The Vacuum Effect: Suctioning Away Dust

As the PCB depaneling machine operates, a cloud of dust is produced. This is where the dust collector steps in. It employs a powerful suction system, often using vacuum motors, to draw the dust away from the work area. The collected dust is then transported to a designated collection point within the dust collector.

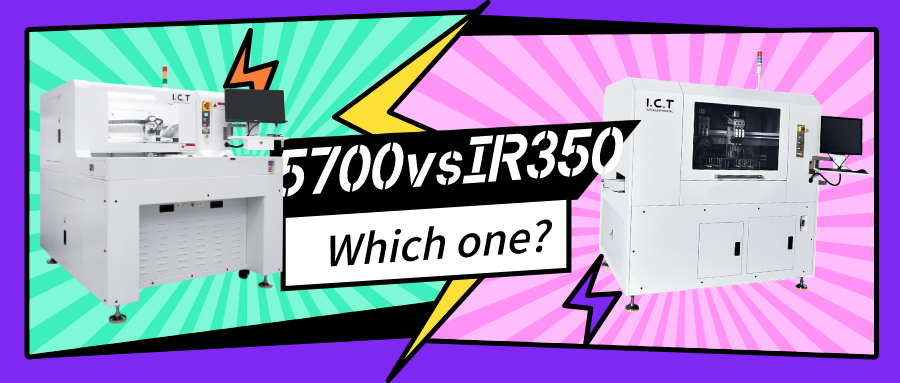

A Difference in Design: I.C.T-5700 vs. I.C.T-IR350

One notable distinction between PCB depaneling machines is the placement of the dust collection apparatus. In the I.C.T-5700, the dust collection system is situated beneath the machine, effectively capturing falling dust as it descends. In contrast, the I.C.T-IR350 features a top-mounted dust collection system, which prevents dust from settling on the work surface.

This strategic difference in dust collection design ensures that, regardless of the PCB depaneling machine in use, dust and debris are efficiently removed, guaranteeing a clean and precise manufacturing process.

Please kindly Check: If you want to learn about the compare of I.C.T-5700 and I.C.T-IR350

The Importance of Filter Replacement

The dust collector’s filter is at the heart of its efficiency. These filters need periodic replacement, typically every 1-3 years, depending on the usage frequency of your PCB depaneling machine. Regular filter maintenance ensures your dust collector performs optimally.

Dust Collectors:Keep Your PCB Manufacturing Clean and Precise

Precision in PCB manufacturing isn’t just about cutting-edge machinery; it’s also about cleanliness. If you’re in the market for a dust collector for your PCB depaneling machine, contact us today to explore your options. Ensure your operations stay clean, efficient, and up to the high standards of modern PCB manufacturing. Don’t let dust compromise your precision – let’s keep it clean together!