Exploring Dispensing Valves and Their Applications

Dispensing valves play a crucial role in precision application across industries, especially in the demanding requirements of the Surface Mount Technology (SMT) sector. Choosing the ideal dispensing valves hinges on three key factors: the valve’s operational mechanism, fluid attributes, and the specifics of the dispensing tasks. A comprehensive comprehension of how these valves operate and their interaction with the substances being dispensed greatly streamlines the selection process, ensuring a precise fit for I.C.T’s range of dispensing machines in the SMT industry.

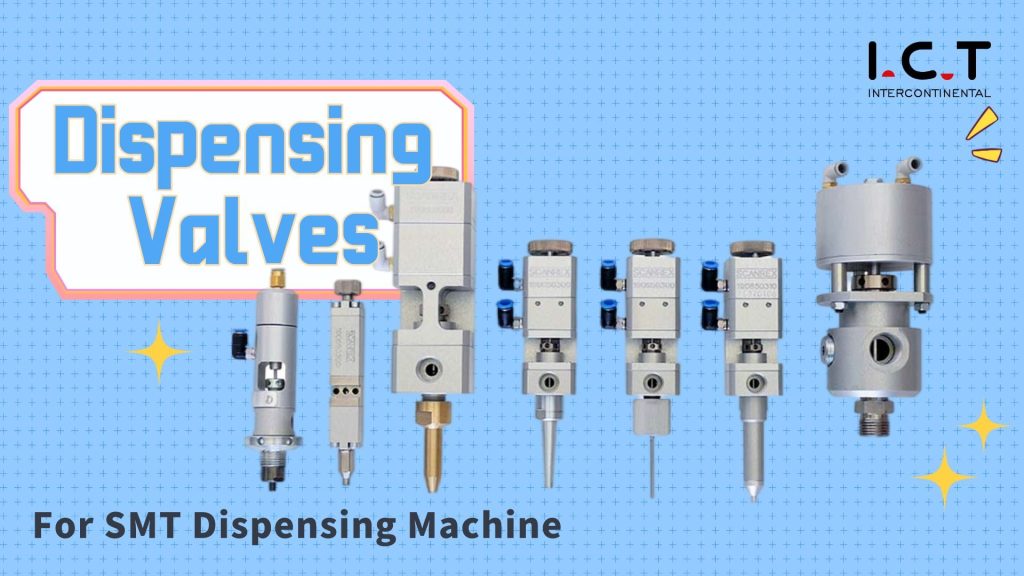

I. Different Operational Principles of Dispensing Valves

Dispensing operations often favor pneumatic dispensing valves due to their speed and reliability. These valves are typically actuated by timed air pulses, allowing the controlled release of the material. There are at least seven classifications of pneumatic valves, each tailored for specific dispensing needs:

1. Spray Valves

Ideal for low-viscosity fluids, especially those below 1000cps, spray valves work well for fluids like solvents or three-proof coatings.

Using non-contact dispensing, the jet valve operates at high speeds, achieving a maximum dispensing rate of 20 dots per second—3 to 7 times faster than traditional methods. It offers high precision with a minimum dispensing volume of 5 nanoliters, ensuring stability comparable to conventional methods. Its non-contact feature eliminates interference between the needle and the workspace, making it ideal for ultra-small dispensing volumes. Additionally, it boasts low maintenance costs and a long lifespan.

2. Needle Valves

Known for their versatility with various single-component fluids, needle valves excel in microdot dispensing applications and are adjustable, accommodating high-pressure dispensing of non-filling, high-viscosity fluids.

Employing a needle tip to manage adhesive flow, the needle valve is suitable for applications demanding extremely small dispensing volumes, such as packaging microelectronic devices.

3. Diaphragm Valves

Suited for adjustable and high-frequency dispensing applications, diaphragm valves work with low to medium viscosity fluids such as adhesives, solvents, and abrasive materials. They are lightweight and easy to maintain.

Controlling adhesive flow through membrane vibration, the diaphragm valve suits higher viscosity adhesives, enabling precise dispensing control.

4. Snuf Valve (Short Path Valve)

Appropriate for highly viscous or gel-like fluids, snuf dispensing valves operate under high pressure and often facilitate line dispensing or trace dispensing along a sealing ring trajectory.

5. Lift Valve

Similar to the snuf dispensing valves but more suitable for low to medium viscosity fluids, offering finer control over dispensing volume.

6. Pinch Valve

With disposable wetted parts, pinch valves are excellent for dispensing solvent-based corrosive fluids and ensure moderate precision and repeatability. They are commonly used for two-component mixtures and instant cure materials.

7. Volume dispensing valves

Utilized for high-precision microdispensing, volume valves come in two types: pneumatic and electrically controlled (screw) dispensing valves. The choice between the two depends on the fluid’s viscosity and desired dispensing volume.

II. Fluid Characteristics and Dispensing Applications

1. Viscosity

Different industrial fluids require specific valves to ensure seamless dispensing. For low viscosity fluids like quick-curing materials (100cps), valves must prevent channel blockages during dispensing cycles and effectively separate air-driven components from wetted parts.

For water or similarly low-viscosity fluids, suitable valves include pinch valves, needle valves, or diaphragm valves. Medium viscosity fluids might work well with pneumatic-operated needle valves.

For highly viscous materials (500,000cps) containing abrasive fillers, pneumatic valves with robust components are preferred, although frequent maintenance may be necessary due to the abrasive nature of the material.

2. Thixotropy

In addition to viscosity, some fluids exhibit thixotropic behavior, making pouring challenging but manageable after agitation. These fluids, similar to tomato ketchup, might require specific handling mechanisms, often involving degassing before dispensing. Depending on their viscosity, different valves like short path, lift valves, and high-pressure needle valves might be recommended.

3. Corrosive Properties

Fluid hardness is crucial, especially when dealing with corrosive substances like acids, alkalis, and solvents. Diaphragm valves or pinch valves with disposable parts are effective as they lack wetted components that could react with corrosive materials.

4. Abrasiveness

Materials with abrasive characteristics, like adhesives containing aggressive fillers, demand robust dispensing mechanisms with components made from high-hardness stainless steel. Regular replacement or disposable parts are advisable to minimize downtime for maintenance.

5. Solidification Rate

Solidification rates during automated dispensing processes can significantly impact the continuity of the operation. Quick-curing fluids may necessitate continuous monitoring and timely purging to maintain consistent dispensing.

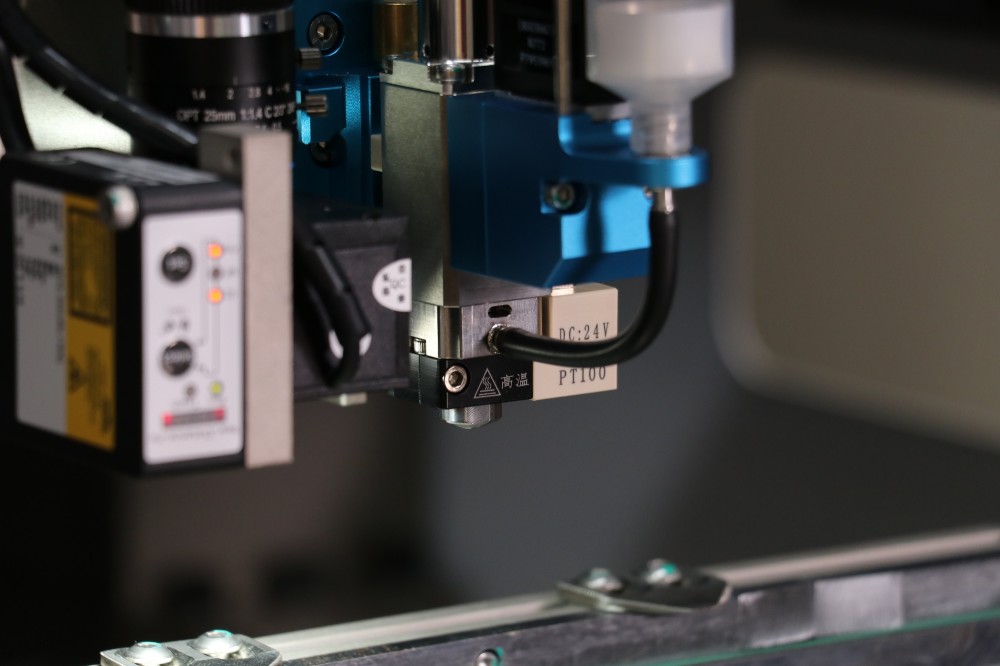

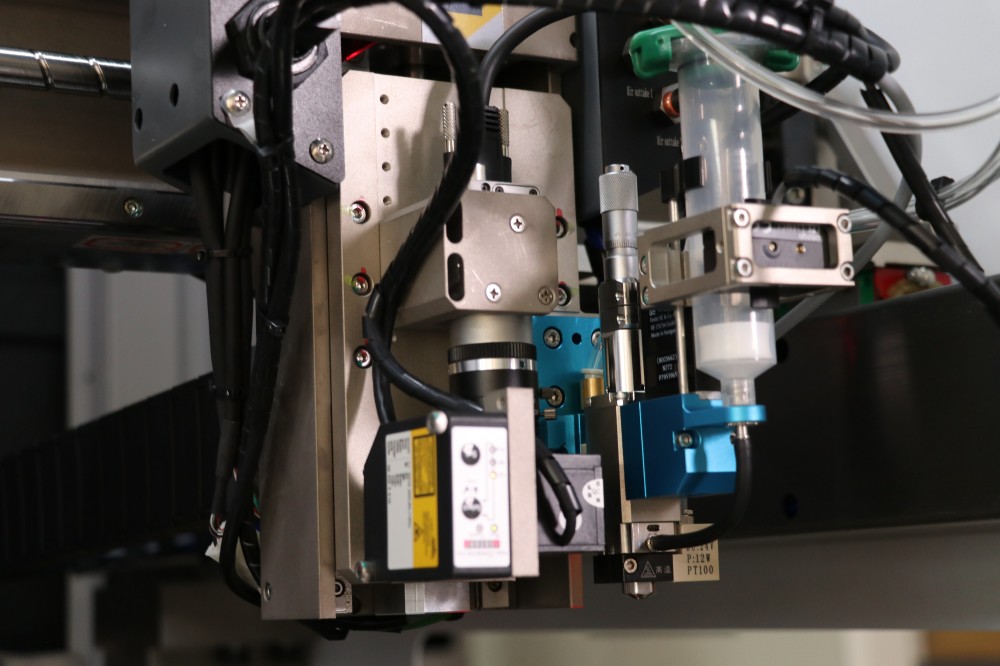

Additionally, temperature-controlled systems might be necessary to ensure constant fluid viscosity throughout the dispensing equipment, reducing downtime.

6. Anaerobic Fluids

Anaerobic fluids solidify in the absence of air, requiring dispensing components and wetted parts that allow air passage. Diaphragm and pinch valves with plastic wetted components are preferable in such cases.

Conclusion

Selecting the right dispensing valve involves a nuanced understanding of both the material being dispensed and the valve’s operational capabilities. The dispensing valves discussed are commonly employed in the Surface Mount Technology (SMT) industry. Spray valves and Needle Valves are frequently used in this sector. Additionally, I.C.T offers several dispensing machines, such as the I.C.T-D600 and I.C.T-D1200. To navigate the selection process for the appropriate equipment and dispensing valves, I.C.T’s engineering team provides direct and personalized assistance, ensuring that the right device and valve choice align with the specific needs of the industry and individual applications. If you have any question, please inquiry in below directly, and we will contact you as soon as possible.