I.C.T Rework Selective Wave Soldering Machine – Precision Soldering Excellence

Explore our in-line and off-line selective wave soldering solutions. Choose based on your specific requirements or Contact Us directly!

Offline model: I.C.T SS430

Online model:

Description

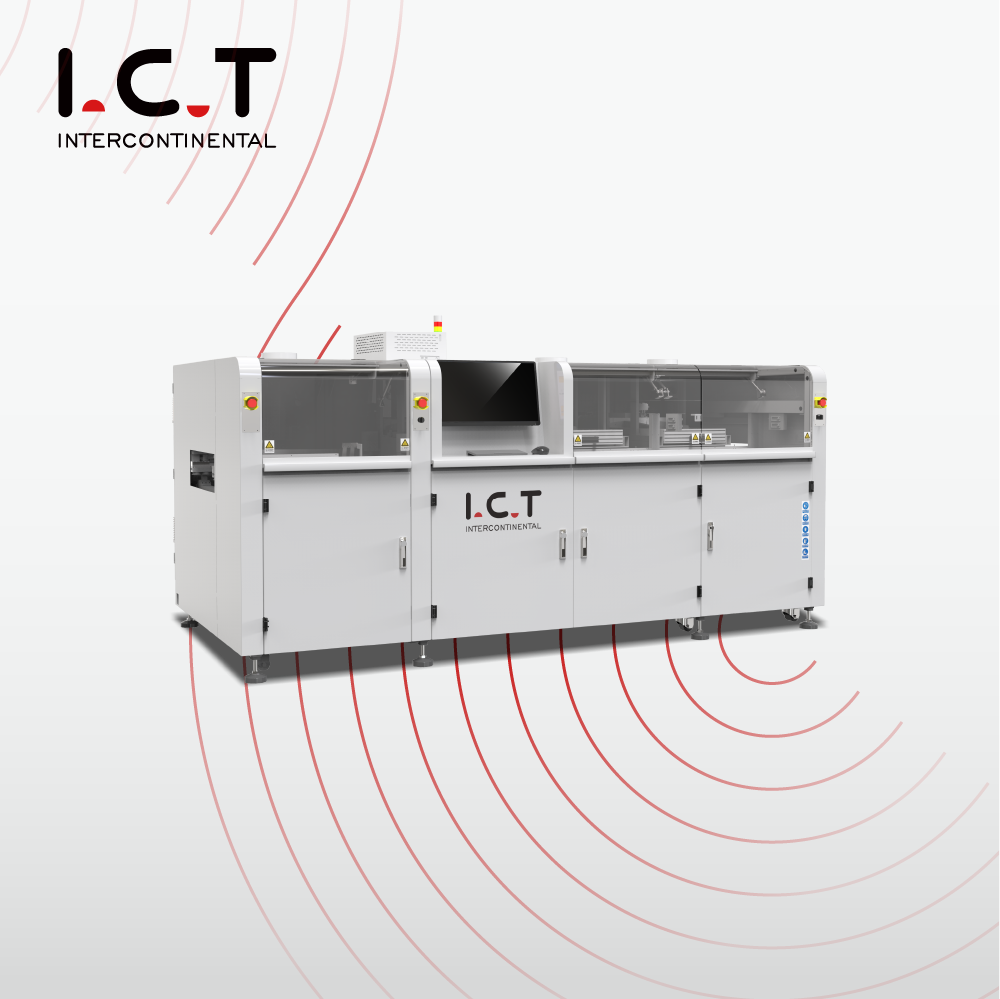

I.C.T-SS550P1 I.C.T Selective Soldering Machine

Advanced I.C.T Rework Selective Wave Soldering Machine

The I.C.T-SS550P1 rework selective wave soldering machine is a cutting-edge solution for high-precision wave soldering. It features a 1 Spray + 1 Preheating + 2 Soldering configuration, enabling parallel processing of fluxing, preheating, and soldering. This efficient setup ensures optimal performance and minimal downtime. With support for up to two spray heads and five lower preheating zones, plus optional upper convection heating, this machine adapts to various production needs.

Ideal for High-End Electronics Manufacturing

The I.C.T rework selective wave soldering machine excels in precision soldering of through-hole components, making it perfect for demanding industries such as military electronics, automotive systems, and switching power supplies. Its ability to integrate seamlessly with assembly stands and traceability systems ensures complete process control and reliable soldering results.

Versatile and Reliable

Designed for complex electronic assemblies, the I.C.T-SS550P1 selective solder machine offers versatility and adaptability in high-volume production environments. It provides precise control over the soldering process, enhancing both efficiency and quality in high-demand applications.

Advantages of I.C.T rework selective wave soldering machine

- Precision and Flexibility

Dynamic Soldering: The fixed PCB plate and dynamic spray/soldering platform ensure precise soldering.

Modular Design: SMEMA-compliant design allows for flexible line configurations.

PC Control: Comprehensive PC control for parameter settings and traceability. - Quality and Efficiency

Superior Soldering: Achieve higher pass rates with advanced soldering technology.

Auto Calibration: Automatic wave height calibration for consistent soldering.

Mark Positioning: Optional feature for accurate PCB mark verification.

Efficient Motion: Lightweight cast aluminum motion table for quick and stable movement.

High-Quality Components: Panasonic servo motors and drivers, ball screws, and linear guide rails for reliable performance. - Durability and Maintenance

Dust Protection: Prevents damage to the ball screw with a dust-proof plate.

Precise Flux Application: German-origin jet valve for accurate flux placement.

Stable Flux Storage: Pressure tank ensures consistent flux delivery.

Reliable Solder Pot: Titanium construction and cast iron heater for durability.

N2 Online Heating: Optimizes soldering and reduces dross.

Durable Conveyor: Stainless steel rollers for long-lasting performance.

Specification of I.C.T rework selective wave soldering machine

PCB Size (with fixture):

12060mm to 500500mm

Flux System:

- Flux Storage Tank: 1.5 L

- Features: Flux alarm with automatic detection

- Spray Nozzle: German jet valve for spot and line spraying (1 set)

- Nozzle Size: 130μm (Optional: 180μm, 210μm)

Preheating System:

- Mode: Hot air and infrared (IR)

- Preheating Area: 500mm x 500mm

- Preheating Zones: 2 top hot air zones, 1 bottom IR zone

- Temperature Range: Room temperature to 250℃

- Control: PC and PLC combined control

Soldering System:

- Double Pot: Optional feature

- Solder Pot: Stainless steel with Japan SURF high-temperature and corrosion-resistant technology

- Wave Control: Electromagnetic pump from Sweden

- Solder Pot Quantity: 1 set

- Solder Capacity: 11 kg

- Temperature Range: Room temperature to 300℃

Transport System:

- Height: 900mm ± 20mm

- Width: 60mm to 500mm

- Adjustment: Automatic width adjustment

Software System:

- Operating System: Windows 10

- Languages: English and Chinese, switchable

- Programming Mode: CCD fast online programming, offline programming, and picture-based programming

Machine Dimensions:

- Size: 2560mm (L) x 1950mm (W) x 1480mm (H)

- Weight: Approximately 1300 kg

Please Contact Us directly for more specifications of the I.C.T SS550 I.C.T rework selective wave soldering machine

Enhancing SMT Assembly Efficiency: Essential Equipment and Expert Support

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.Additional information

| Model | SS550 |

|---|---|

| Flux Storage Tank | 2L |

| Flux Support | Flux Alarm, Automatic |

| Preheating Mode | Hot air and IR |

| Preheating Area | L520mm*W500mm |

| Preheating Zone | Top hot air:1,Bottom IR:1 |

| Warm-up Time | Approx.15min (setting 150℃) |

| Control Mode | PC+PLC |

| Nozzle Inner Diameter | Φ 2.5-30mm(Customizable Special dimensions) |

| Max PCB Size | 500*500mm |

| PCB Thickness | 0.2-5.0mm |

| N2 | Purity of N2: 99.998%, 0.3~0.4 MPa,25 L/min,Outer diameter Φ6mm |

| Power Supply | 380±10%, 50/60HZ, 35Kw |

| Dimension | L2600*W1850*H1650mm |

| Weight | Approx:1800kg |