I.C.T-PP3025 | Multi-Head IC Component PCBA Tray Placement machine

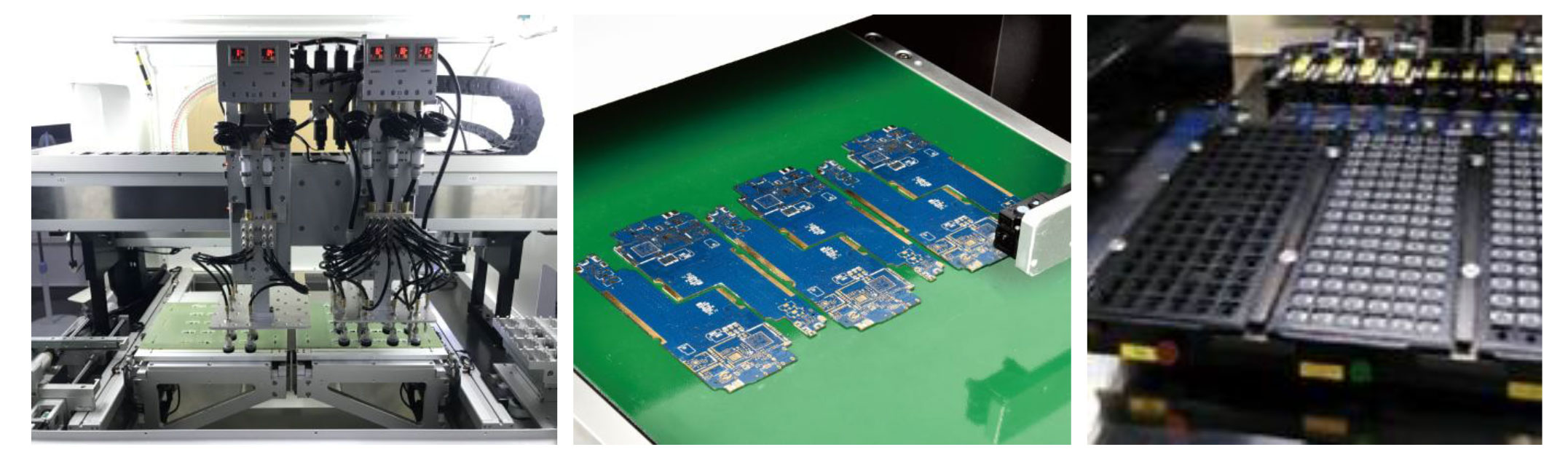

I.C.T-PP3025 | Multi-Head IC Component PCBA Tray Placement machine is designed for automatic splitting machines. It has the characteristics of fastefficiency, labor saving, and high pass rate. It is especially suitable for manufacturers with high anti-static requirements such as automotive electronics and mobile phone motherboards.

Description

I.C.T – PP3025

PCBA Tray Placement machine

Features:

- Automatic feeding: auto feed the products to be placed in the plate after receiving the signal from the front machine.

- Automatic code scanning: CCD detects the product size and has the code scanning function at the same time.

- Automatic pan: CCD guides the suction nozzle to automatically suck OK products to pan.

- Automatically distinguish NG code: NG products are automatically put into the NG plate, and the NG code and fork

plate are put into the defective box. - Automatic stacking tray: automatically supply empty trays and stacking OK finished trays full trays.

- AGV automatically feeds in empty trays and takes away full trays.

- Adopt multi-axis bus control.

- Production capacity: production capacity is about 1800-2000pcs/

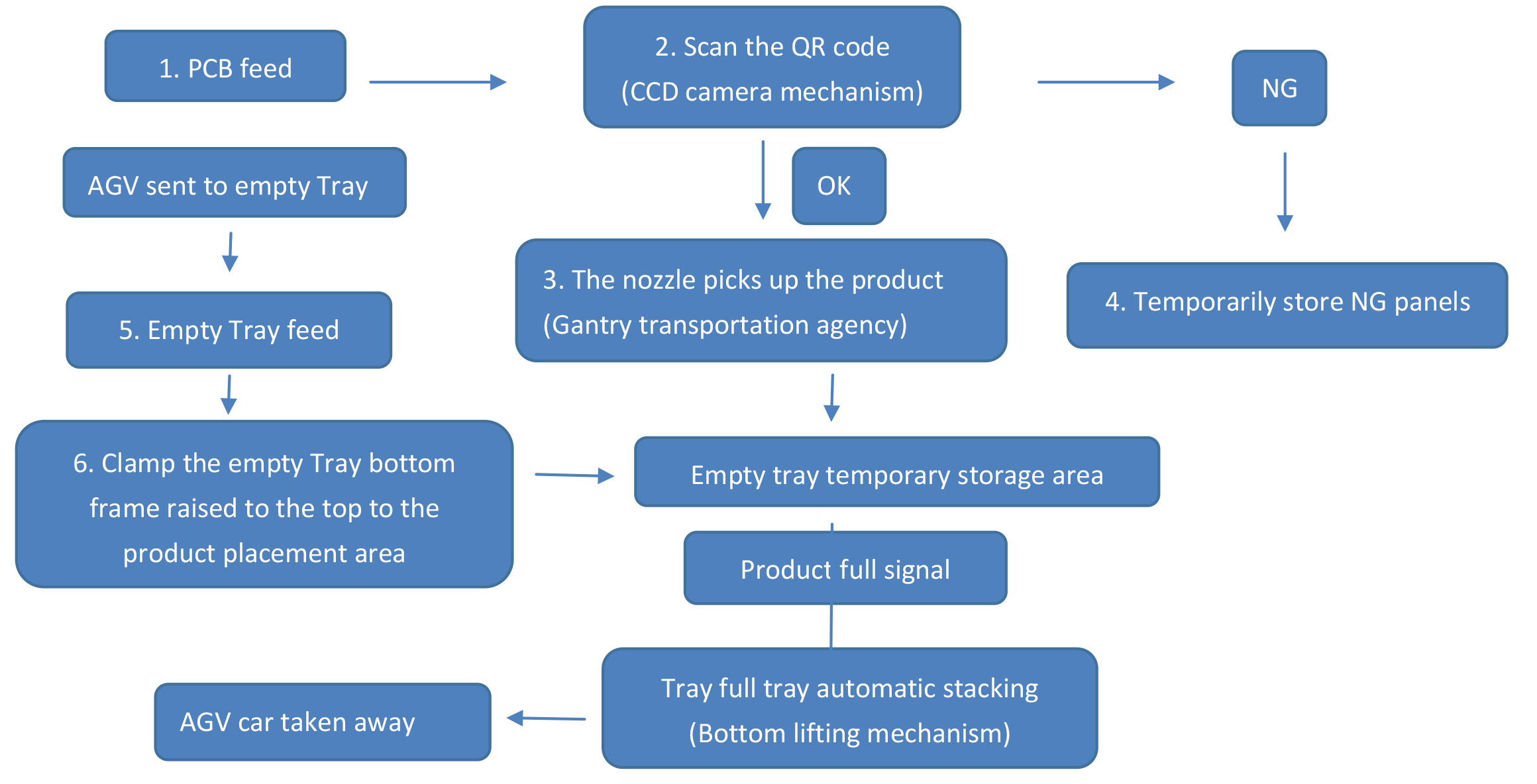

PCBA Tray Placement machine Process:

PCBA Tray Placement machine Application:

Video for your Information:

Additional information

| Model No. | I.C.T-PP3025 |

|---|---|

| Type | Online |

| No. of Nozzles | Six |

| Pallet Quantity | 18*8PCS&19*7PCS |

| Processing Speed | 1800-2000PCS/H |

| Direction | L to R |

| Voltage | AC220V, 50/60Hz |

| Size | 1700 *1350 *1800 mm |

| Weight | 1500kg |

| Communication | SMEMA |