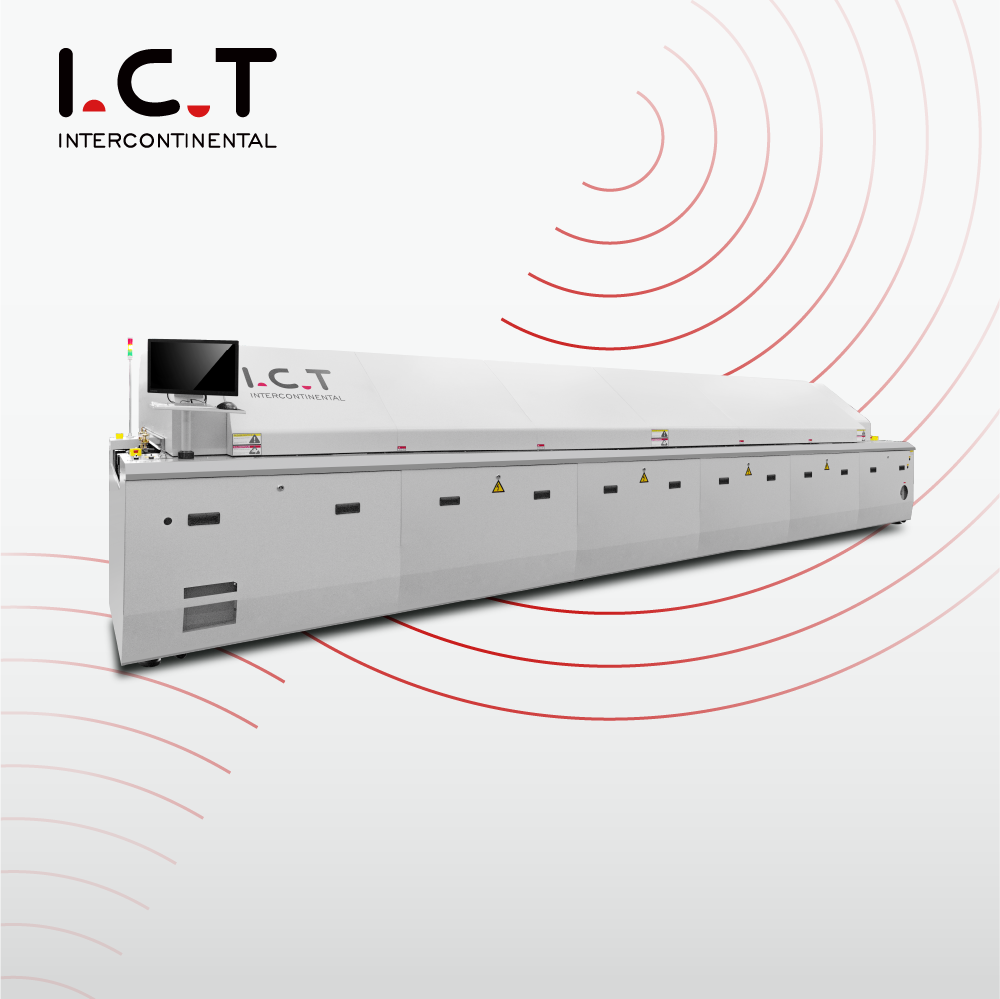

I.C.T-LV623 SMT Vacuum Reflow Oven

Description

I.C.T-LV623 SMT Vacuum Reflow Oven

Key Features of SMT Vacuum Reflow Oven

Transport System

- The SMT vacuum reflow oven has three-stage conveying: heating, vacuum, and cooling zones, all independently adjustable.

- Software controls automatic chain lubricant addition with a customizable cycle.

- Adjustable chain tension extends service life.

- Multiple rigid booms ensure guide rail stability.

- Synchronized guide wheels prevent jamming during SMT vacuum reflow.

- Rail width is adjustable; stepping motors control the preheating and cooling zones, while servo motors manage the vacuum zone for precision.

Heating System

- Insulation between the preheating zone and outer walls enhances heat retention in the vacuum reflow oven.

- Precise temperature control delivers repeatable results.

- The oven ensures process stability with minimal temperature variation.

- Independent control for top and bottom wind speed optimizes heat transfer.

- Multi-layer insulation reduces heat loss at PCB inlets and outlets.

- Unique air duct design prevents interference between temperature zones.

Vacuum Zone

- Fiber sensors detect PCB boards for precise production flow in the SMT vacuum reflow soldering oven.

- The vacuum chamber switch uses a pneumatic design for secure sealing.

- A high-power vacuum pump delivers 5mbar vacuum pressure.

- Independent servo motors ensure stable, accurate track transportation.

- Segmented guide rails prevent PCB jamming.

Cooling System

- Stress-free cooling with individually adjustable cooling zones.

- A closed-loop system allows precise adjustments for any process.

- Suitable for nitrogen cooling processes.

- Standard external water chiller improves cooling efficiency.

Control System

- The PCB vacuum reflow oven design meets CE, UL, and other standards.

- Imported PLC and components ensure reliability.

- High-quality electrical parts enhance stability.

- Industry 4.0 ready with advanced features.

- Real-time temperature monitoring provides precise control with minimal variance.

Operator System

- Simple software interface, easy to operate.

- Store multiple programs for quick product changeovers.

- One-key rail width adjustment.

- Sectional heating reduces energy consumption.

- Vacuum time and degree are adjustable for different production needs.

Specification of SMT Vacuum Reflow Oven:

- Heating & Cooling zones: 8 + 3

- Length of preheating zones: 3110mm

- Max. temperature: 300 ℃

- Max width of PCB: 150*150MM-400*400MM

- Mesh Width: Standard 440mm

- Range of rail width: 50mm-400mm

- Energy consumptions:

– Total power 67KW

– Startup power 32KW

– Normal power consumption 10KW

- Dimensions: L6405*W1695*H1630

- Weight: 3000 kg

Enhancing SMT Assembly Efficiency: Essential Equipment and Expert Support

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.Additional information

| Model | I.C.T-Lyra 733/733N |

|---|---|

| Dimensions | 6250*1400*1500mm |

| Preheating Zones | 7 zones |

| Peak zones | 2 zones |

| Max. soldering temperature | pre-heating zones 300 ℃ and peak zones350 ℃ |

| Warm up time | ca. 20 min |

| Cooling zones | 2 zones |

| Mesh Width | Standard 440mm( Option 560 & 680mm ) |

| Type | SMEMA |

| Type of power system | (L1, L2, L3, N, PE) / 5-Wire-System |

| Voltage supply | 5-Wire System 3P,N,PE 380 VAC ± 5 % 50 Hz Other voltages upon request |