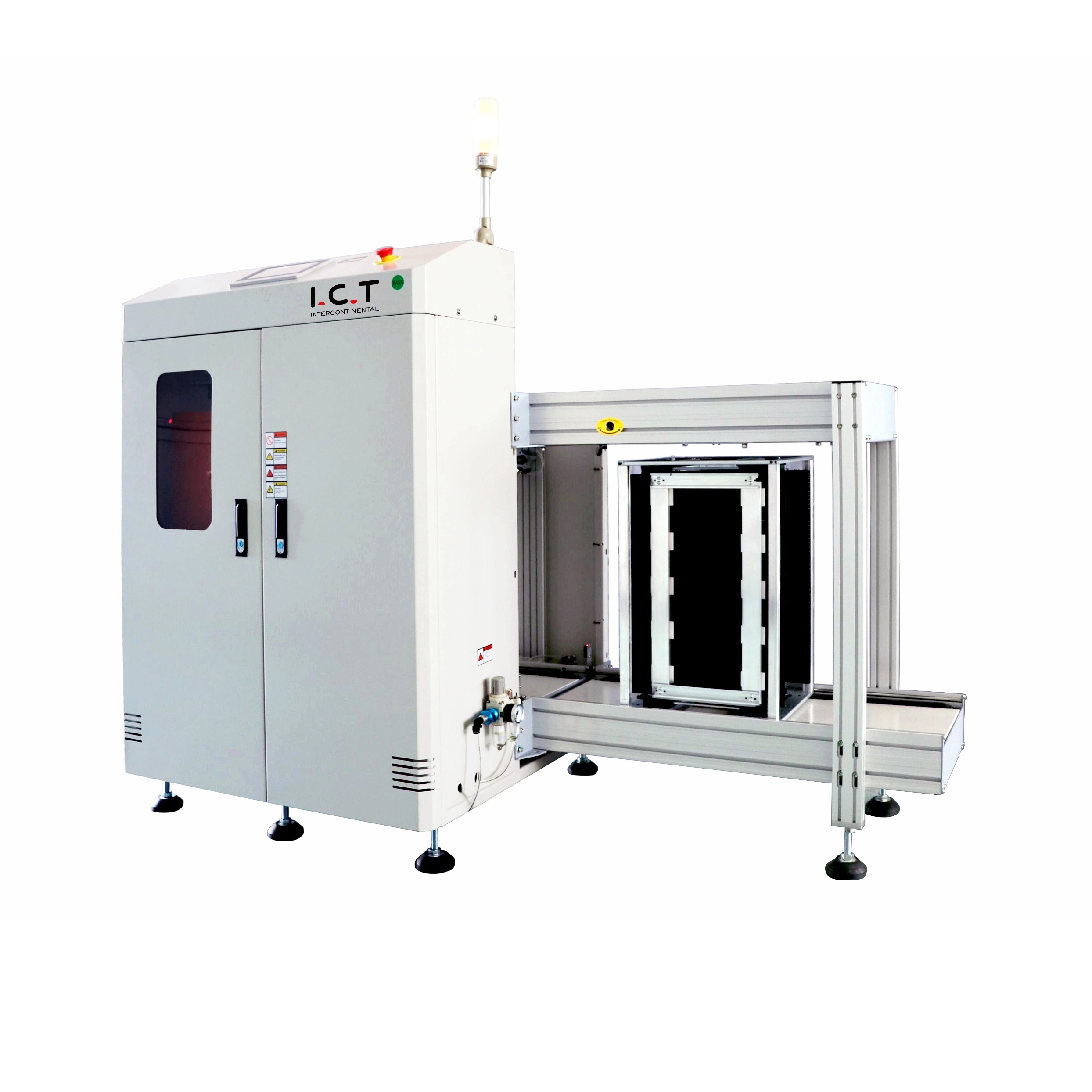

I.C.T-BLD600 | Advanced Upscale SMT PCB Loader For Semiconductor

I.C.T-BLD600 Advanced Upscale SMT PCB Loader For Semiconductor is mainly used for semiconductor packaging and testing, washing the front end of the line body, and transferring the board to the lower computer equipment through the storage method of the clip frame, with automatic feeding function.

Description

I.C.T – BLD600

Advanced Upscale SMT PCB Loader

Features:

- It is mainly used for semiconductor packaging and testing, washing the front end of the line body, and transferring the board to the lower computer equipment through the storage method of the clip frame, with automatic feeding function.

- The control system adopts PLC control.

- The operation interface adopts touch screen.

- Lifting and translation are controlled by servo motor, and the lifting and shifting distance can be set arbitrarily.

- The board feeding method adopts the stepper motor method.

- The frame changing method adopts the platform multi-frame storage method, which has the function of single-frame

feeding and multi-frame feeding at the same time. - The positioning method of the mechanical card-type bin can be adjusted arbitrarily for bins of different sizes.

- Equipped with standard SMEMA communication port, which can communicate with other automation equipment.

Tips: What is PCB handling equipment?

PCB handling equipment refers to machines or devices used in the production, assembly, or testing of printed circuit boards (PCBs). These devices are designed to safely and efficiently handle PCBs during various stages of the manufacturing process. Some common types of PCB handling equipment include:

1.PCB loaders and unloaders: These machines are used to automatically load and unload PCBs onto assembly lines or testing equipment.

2.Conveyors: These are systems of belts, rollers, or other mechanisms that move PCBs between different stages of production or testing.

2.Magazine loaders and unloaders: These machines are used to load or unload PCBs into or out of production magazines, which hold PCBs in a vertical orientation for efficient storage and handling.

3.Depaneling equipment: These machines are used to separate individual PCBs from larger panels after assembly or testing is complete.

5.Inspection equipment: These machines are used to inspect PCBs for defects or damage, either during or after production.

Overall, PCB handling equipment plays an important role in ensuring the quality, efficiency, and safety of PCB manufacturing processes.

Additional information

| Item | I.C.T-BLD600 / I.C.T-BUL600 |

|---|---|

| PCB Board size (mm) | 80*50~330*120 |

| Transmission height (mm) | 900±20 |

| PCB Loading time | 6-16 sec |

| Magazine size | 80*50*100-300*150*400 |

| PCB thickness | 0.2-2.0mm |

| Transmission direction | L to R/R to L |

| Compressed air pressure | 0.4~0.6Mpa |

| Power | AC220V±10V, 50/60HZ 450W |

| Machine size | 1000х1100х1300 mm |

| Machine | 240KG |

Reviews

There are no reviews yet.