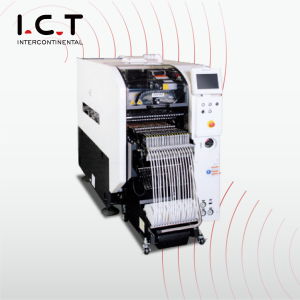

High-Speed Compact Modular Chip Mounter JUKI RX-6R/RX-6B

Brand new Modular Mounter RX-6 debut

-Combine High Productivitiy, High Flexiblity, High Quality

Description

JUKI RX-6R/RX-6B

High Speed Compact Modular Mounter

Juki’s already reliable technology has evolved to an all new level! The compact RX-6R/RX-6B offers high productivity, flexibility and quality – in a compact footprint.

- This is applicable to dual-lane production.

- Compact footprint : the width is just 1.25m

- Equipped with standard Placement Monitor check function.

- Replaceable head allow you to configure a production line best suited to the current repirments.

- High-speed component placement using high-speed non-stop vision recognition.

- Wide range of components and boards: tall components, large components and large boards.

- Brand new Matrix Tray Sever TR8S improves the component capability and productivity.

Tips: What is SMD and SMT?

SMD (Surface Mount Device) and SMT (Surface Mount Technology) are two related terms used in the electronics industry to refer to the same technology of mounting electronic components on the surface of a printed circuit board (PCB).

SMD refers specifically to the individual electronic components, such as resistors, capacitors, and diodes, that are mounted directly onto the surface of the PCB without the need for through-holes. These components are typically much smaller than their through-hole counterparts, which allows for greater component density and more compact PCB designs.

SMT, on the other hand, refers to the entire process of assembling and mounting these SMD components onto the PCB surface. This includes the use of specialized equipment, such as pick and place machines, to accurately place the components onto the PCB and the use of reflow soldering to connect them to the PCB pads.

Overall, SMD and SMT are both used to describe the same technology of surface-mounting electronic components onto a PCB, but SMD specifically refers to the components themselves, while SMT refers to the entire process of surface-mount technology.

Additional information

| Model 1 | JUKI RX-6R |

|---|---|

| Model 2 | RX-6B |

| Board size | Single lane conveyor: 50×50 ~ 610×590 / 905×590mm (2 times clamping) |

| Component height | 6 / 12 / 20 / 25 / 33mm |

| Component size | Standard camera: 3mm×3mm ~ 33.5mm×33.5mm |

| Placement speed | Optimum*3: 42,000CPH |

| Placement accuracy | Laser recognition: ±0.04mm(Cpk≧1) |

| Component loading quantity | Max.160 in case of 8mm tape(on a Electric double tape feeder) |