Hanwha HM520 MF | PCB Chip Mounter High Speed

HM520 MF PCB Chip Mounter distinctive features shine in creating a flexible production line, incorporating a modular head and diverse production methods. The integration of a high-speed, high-definition camera elevates its capabilities, enabling rapid and precise positioning of mini chips, LEDs, and microchips (0402mm-55mm). The cutting-edge camera technology ensures high-speed operations without compromising actual output.

Description

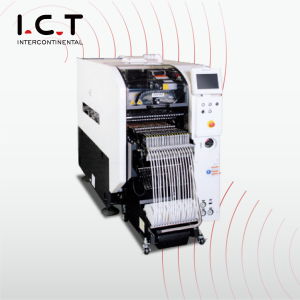

Hanwha HM520 MF | PCB Chip Mounter

Hanwha HM520 MF PCB Chip Mounter – a pinnacle in PCB assembly technology. The HM520MF stands out with the highest productivity in its class, meticulously optimized for top-tier quality production.

Its distinctive features shine in creating a flexible production line, incorporating a modular head and diverse production methods. The integration of a high-speed, high-definition camera elevates its capabilities, enabling rapid and precise positioning of mini chips, LEDs, and microchips (0402mm-55mm). The cutting-edge camera technology ensures high-speed operations without compromising actual output.

Choose the HM520MF PCB Chip Mounter for unmatched performance, where productivity, precision, and adaptability converge for superior PCB assembly.

Specification of Hanwha PCB Chip Mounter hM520 MF

Hanwha HM520 MF PCB Chip Mounter High Speed and Highly Flexible

- Alignment

– Fix Camera

- Number of Spindles

– 6 spindles x 2 Gantry (Rotary Type)

- Placement Speed

– 60,000 CPH (Optimum)

- Placement Accuracy

– ±40 μm @ Cpk ≥ 1.0 (Chip) / ±30 μm @ Cpk ≥ 1.0 (IC)

- PCB Size (mm)

Single

– 50 x 40 – 510 x 580mm (Standard)

– 50 x 40 – 750 x 580mm (Option)

Double

– 510 x 310mm (Standard)

– 750x330mm (Option)

- Feeder Capacity (8mm standard)

– 120

- Component Height

– 15 mm

- Component Range

– 0402 ~ □ 55 mm

- Machine Size

– 890×2,312×1,921

- Machine Weight : 1605 kg

Core System & Function Of PCB Chip Mounter

1. Unrivaled Productivity: The Hanwha HM520 MF PCB Chip Mounter sets the benchmark with the highest actual productivity in its class. Experience unmatched efficiency for your PCB assembly needs.

2. Precision-Optimized Production: Tailored for excellence, the HM520 MF PCB Chip Mounter is intricately optimized to deliver high-quality production. Every component placement is executed with precision, ensuring superior results.

3. Smart Factory Integration: Elevate your operations with the Smart Factory S/W Solution. The PCB Chip Mounter operates seamlessly in an unmanned, non-stop mode, achieving zero defects. Experience the future of PCB assembly with intelligent software solutions.

Choose the Hanwha HM520 MF PCB Chip Mounter for a combination of unparalleled productivity, precision-optimized production, and seamless integration into the Smart Factory environment.

Optimizing SMT Assembly Efficiency: Vital Equipment and Proficient Support

Don’t hesitate to Contact us. We aim to establish seamless communication and offer prompt assistance. Whether you seek guidance or equipment, the I.C.T team is ready to meet your requirements swiftly. At I.C.T, we are dedicated to ensuring a smooth and efficient SMT assembly process for our valued clients.

Don’t hesitate to Contact us. We aim to establish seamless communication and offer prompt assistance. Whether you seek guidance or equipment, the I.C.T team is ready to meet your requirements swiftly. At I.C.T, we are dedicated to ensuring a smooth and efficient SMT assembly process for our valued clients.

Additional information

| Model | DECAN S1 |

|---|---|

| Alignment | Fly Camera, Fix Camera |

| Spindle & Speed | 1 Gantry * 10 Spindle / 47,000 CPH |

| Accuracy | ±28μm @ Cpk≥ 1.0 (Chip) / ±30μm @ Cpk≥ 1.0 (IC) |

| Component Range | Fly: 03015 ~ □16 mm / Fix: ~□42 mm (Standard) / ~□55 mm (MFOV) / ~ L75 mm Connector (MFOV) |

| PCB Size (mm) | Min.: 50(L) x 40(W) |

| PCB Thickness (mm) | 0.38 ~ 4.2 |

| Feeder Capacity (8 mm Standard) | Standard: 60ea / 56ea (Fixed feederbase / Docking Cart) |

| Weight (kg) | Approx. 1,600 |

| Dimension | L 1,430 x D 1,740 x H 1,485 |