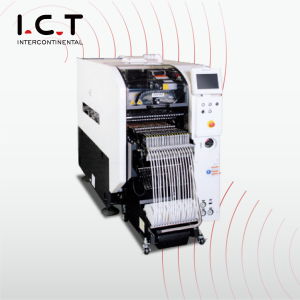

Hanwha DECAN S1 | Pick and Place Machine

Unleash your production line’s full potential with Hanwha Decan S1 Pick and Place Machine. With 10 spindles, 1 Gantry, and a placement speed of 47,000 CPH (Optimum), achieve unparalleled accuracy and efficiency. Hanwha offers a range of high-performance pick and place machines, including:

Description

Hanwha Decan S1 | Pick and Place Machine

Hanwha Pick and Place Machine: The Ultimate SMT Solution for Your Production Line

Discover the Hanwha Pick and Place Machine – the industry-leading SMT solution designed to optimize your production line. With precision, speed, and reliability, Hanwha ensures efficient and accurate electronic component placement for maximum quality output. Upgrade your manufacturing process with Hanwha’s cutting-edge technology.

Hanwha Pick and Place Machine offers an unparalleled experience in the world of Surface Mount Technology (SMT). Recognized globally for its exceptional accuracy, speed, and durability, the Hanwha machine is designed to revolutionize your electronic manufacturing process.

Specification of Decan S1 Pick and Place Machine

Fast & Flexible Pick and Place Machine

- Alignment

– Fly Camera + Fix Camera

- Number of Spindles

– 6 Spindle x 1 Gantry

- Placement Speed

– 47,000 CPH (Optimum)

- Placement Accuracy

– Chip ±28μm @ Cpk≥ 1.0

– IC ±35μm @ Cpk≥ 1.0

- PCB Size

– 50(L) x 40(W) – 510(L) x 510(W)

– Option ~ Max. 1,500(L) x 460(W)

- Feeder Capacity (8mm standard)

– Standard 60ea / 56ea (Fixed feederbase / Docking Cart)

– Option 120ea / 112ea (Fixed feederbase / Docking Cart)

- Component height:

– Max. Height 10mm (Fly), 15mm (Fix)

- Component size

– Fly Camera 03015 ~ □16mm

– Fix Camera~ □42mm (Standard) / □42mm ~ □55mm (MFOV) / L55mm ~ L75mm Connector (MFOV)

- Machine Size

– 1,430(L) x 1,740(D) x 1,485(H)

- Machine Weight : 1600 kg

Core System & Function Of Pick and Place Machine

Experience unparalleled efficiency with the Hanwha DECAN S1, designed to revolutionize your production processes. Elevate your manufacturing capabilities with key features tailored to enhance performance and reduce losses:

-

- Improves Actual Productivity: Enhance your manufacturing output with the DECAN S1, optimizing efficiency and reducing production time for a wide range of applications.

- Improves Placement Quality: Achieve precision in component placement, ensuring high-quality assembly for your electronic products using the state-of-the-art pick and place machine.

- Reduces Loss Rate: Minimize material wastage and increase cost-effectiveness by leveraging the machine’s advanced features to significantly reduce the loss rate in your pick and place processes.

- Highest Performance in Class: Benefit from the industry’s highest performance among chip mounters, setting new standards for speed and accuracy in pick and place machine, specifically the Hanwha DECAN S1.

- Highest Applicability for PCBs: Explore versatile PCB compatibility with standard sizes of 510 x 510mm and an optional expansion to 1500 x 460mm, showcasing the pick and place machine’s adaptability to diverse production needs.

- Expands Component Recognition Range: Utilize the high-pixel camera of the Hanwha DECAN S1 to recognize components from 03015 to 16mm, expanding its versatility in handling various chip sizes during the pick and place process.

- Improves Simultaneous Pickup Rate: Enhance operational efficiency through automatic pocket position arrangement, facilitated by seamless communication between the pick and place machine and feeder.

- Improves Placement Speed for Odd-Shape Components: Optimize speed by approximately 25% with a fix camera-optimized motion sequence, ensuring swift and precise placement of odd-shape components using the Hanwha DECAN S1.

- Stable Placement of Microchips: Achieve stability in microchip placement with the Hanwha DECAN S1, contributing to overall product reliability and quality in the pick and place process.

- Recognizes Nozzle Center: Improve microchip loss rate and placement quality by preventing air leaks through accurate recognition of the nozzle center in the pick and place machine.

- Run Time Calibration: Maintain placement accuracy with automatic calibration during production, ensuring consistent and reliable results in the pick and place process with the Hanwha DECAN S1.

- Auto Maintenance for Error Prevention: Enhance operational reliability with auto maintenance features, including pneumatic pressure and flow rate measurement, as well as high-pressure air blast for foreign material removal in the pick and place machine.

- Increased Convenience of Operation: Streamline your manufacturing processes with reduced teaching time for large odd-shape components and improved overall convenience using the pick and place machine.

- Unified Chip Component Lighting Level: Minimize lighting changing time by collectively setting the same lighting value, reducing productivity deviations and improving part database management with the pick and place machine.

- Support for Multi-Vendor Components: Seamlessly manage components from different suppliers under one part name, allowing continuous production without altering the PCB program using the pick and place machine.

- Easy Teaching of Large-sized Components: Simplify the teaching process for large-sized components with panoramic view recognition, enabling efficient pickup/placement position determination with the pick and place machine.

Note: Auto Maintenance function available from December 2018, and Multi-Vendor function available from October 2018, marking the commitment to continuous improvement and innovation in the pick and place machine.

Enhancing SMT Assembly Efficiency: Essential Equipment and Expert Support

The LED Solder Printer stands as a crucial element within the SMT assembly line, working hand in hand with other vital machinery like the Pick and Place machine, Reflow Oven, Loader & Unloader, Conveyor, and more. If these components seem unfamiliar, our dedicated team of I.C.T. engineers is readily available to offer their SMT expertise. Additionally, explore our extensive portfolio of case studies, highlighting successful client services. All our equipment proudly carries CE certification, ensuring compliance with rigorous European safety standards.

For any inquiries or specific needs, don’t hesitate to Contact us. Our goal is to establish seamless communication and provide swift assistance. Whether you’re in search of guidance or equipment, I.C.T team is here to cater to your requirements promptly. At I.C.T, we’re committed to facilitating a smooth and efficient SMT assembly process for our valued clients.

Additional information

| Model | SM471Plus |

|---|---|

| Alignment | Fly Camera |

| Spindle & Speed | 2 Gantry * 10 Spindle / 78,000 CPH |

| Accuracy | ±40μm@±3σ (Chip) / ±50μm@±3σ (QFP) |

| Component Range | 0402 ~ □14mm |

| PCB Size (mm) | Single Lane: L510 x W460~ L610 x W460 (Option) |

| PCB Thickness | 0.38 ~ 4.2 |

| Feeder Capacity (8mm standard) | 120ea/112ea (Docking Cart) |

| Dimension | L 1,650 x D 1,690 x H 2,045 |