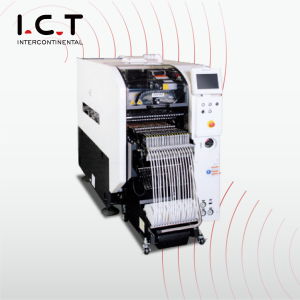

JUKI LX-8 | Advanced Flexible Mounter

Experience unparalleled speed and precision with the JUKI LX-8 Advanced Flexible Mounter. Capable of achieving an impressive speed of up to 105,000 CPH and boasting an accuracy rate of ±40 μm, the LX-8 stands as the epitome of cutting-edge technology in the realm of SMT placement machines.

Description

JUKI LX-8 | Advanced Flexible Mounter

Experience unparalleled speed and precision with the JUKI LX-8 Advanced Flexible Mounter. Capable of achieving an impressive speed of up to 105,000 CPH and boasting an accuracy rate of ±40 μm, the JUKI LX-8 Advanced Flexible Mounter stands as the epitome of cutting-edge technology in the realm of SMT placement machines.

The JUKI LX-8 stands out for its versatile design, offering users the choice between the P20 rotary planet head and the Takumi Head with adjustable height. This flexibility ensures precise component placement tailored to the unique needs of each project, whether it involves intricate designs or rapid production runs. The LX-8 is engineered to deliver exceptional performance in any scenario.

Equipped with two P20S 20-nozzle planet heads, the JUKI LX-8 achieves unprecedented speeds in its class, reaching up to 105,000 CPH. Despite its remarkable speed, the machine maintains an outstanding accuracy rate of ±40 μm (Cpk ≥1), ensuring precision and quality in every placement. The LX-8 emerges as the fastest machine available without compromising on precision standards.

Specification of JUKI LX-8 Advanced Flexible Mounter

Advanced Flexible Mounter JUKI LX-8

- Model configuration

– P20S x2

– P20S + Takumi

– Takumi + Takumi

- Mounting Speed:

– 105,000CPH P20S x2

– 99,500CPH P20S + Takumi

– 94,000CPH Takumi + Takumi

- PCB Size

– Single clamping: 50×50~410mm x 400mm/500mm

– Double clamping: 50×50~810mm x 400mm/500m

- Placement accuracy ±40um (25um)(Cpk ≧1) / ±30um (Cpk ≧1)

- Feeder Count

– Tape

Max. 136 P20S x2

Max. 148 P20S + Takumi

Max. 160 Takumi + Takumi

Tray

– P20S x2

Max. 30 P20S + Takumi

Max. 60 Takumi + Takumi

- Component height: 3- 25㎜

- Component size 0201*1 ~□74 ㎜ /150×50 ㎜

- Machine Size

– 1,600 ㎜ ×1,924 ㎜ ×1,440 ㎜

- Machine Weight : 2400 kg

Core System & Function Of Advanced Flexible Mounter

- Advanced Flexible Mounter Excellence: The JUKI LX-8 Advanced Flexible Mounter stands as a pinnacle of cutting-edge technology, ensuring the realization of highly efficient production through exceptional area productivity.

- Intuitive User Experience: A new user interface has been meticulously designed, prioritizing ease of use. This enhancement not only streamlines operations but also contributes to a smoother and more intuitive user experience.

- Unmatched Feeder Capacity: Boasting 160 or more feeder slots, the JUKI LX-8 claims the largest capacity in its class. This substantial feeder capacity significantly reduces changeover time, enhancing overall production efficiency.

- Front-Side Banks for Continuous Operation: The LX-8 allows front-side banks to operate seamlessly without any loss of productivity. This innovative feature contributes to uninterrupted workflow and increased operational efficiency.

- Optimized Independent Head Configuration: With an independent head configuration, the LX-8 minimizes tact loss, ensuring optimal performance and precision in component placement.

- Versatile Component Handling: The JUKI LX-8 accommodates components ranging from 0.3mm×0.15mm up to 65mm square, with variations such as 10mm×90mm, 50mm×75mm, and up to 25mm tall. This versatility caters to a wide range of production requirements.

- Enhanced Inspection Capabilities: Featuring a new high-accuracy camera for inspection and centering, the LX-8 ensures precise quality control. The reduction in VCS image-recognition times, when compared with our equipment, further enhances inspection efficiency.

- Seamless Integration: The JUKI LX-8 seamlessly integrates with the production environment, offering compatibility and ease of incorporation into existing workflows. This adaptability enhances overall production line efficiency.

Enhancing SMT Assembly Efficiency: Essential Equipment and Expert Support

The JUKI Advanced Flexible Mounter stands as a crucial element within the SMT assembly line, working hand in hand with other vital machinery like the PCB Printing Machine, Reflow Oven, Loader & Unloader, Conveyor, and more. If these components seem unfamiliar, our dedicated team of I.C.T. engineers is readily available to offer their SMT expertise. Additionally, explore our extensive portfolio of case studies, highlighting successful client services. All our equipment proudly carries CE certification, ensuring compliance with rigorous European safety standards.

For any inquiries or specific needs, don’t hesitate to Contact us. Our goal is to establish seamless communication and provide swift assistance. Whether you’re in search of guidance or equipment, I.C.T team is here to cater to your requirements promptly. At I.C.T, we’re committed to facilitating a smooth and efficient SMT assembly process for our valued clients.

Additional information

| Board Size | Min. 50mm X 50mm |

|---|---|

| Component Specs | Component Height: 25mm |

| Placement Specs | Placement Speed : 31,000CPH (IPC9850) |

| Component height | 25 mm |

| Component size | 0201*1 ~□74 ㎜ /150×50 ㎜ |

| Placement speed | Optimum: 47,000CPH |

| Placement accuracy | ±35μm(Cpk≧1) |

| Feeder Input | max.112*2 |