11 Features of the I.C.T In-Line AOI Inspection Machine: Efficient and Easy to Use

Introduction of Online AOI Inspection Machine

In today’s rapidly evolving electronics industry, the demand for high-quality, defect-free products is greater than ever before. To meet these stringent quality standards, manufacturers are turning to advanced technologies such as Automated Optical Inspection (AOI). Among the cutting-edge AOI solutions available, the Online AOI Inspection Machine stands out as a game-changer. This article explores the key features and benefits of this remarkable piece of equipment, designed to revolutionize Surface Mount Technology (SMT) pre-reflow and post-reflow inline inspections.

Comprehensive SMT Inspection

The Online AOI Inspection Machine is engineered to perform comprehensive inspections at two critical stages of the SMT assembly process: pre-reflow and post-reflow. This dual capability ensures that potential defects are identified early in the process, minimizing costly rework and reducing the risk of shipping defective products to customers.

Exceptional Inspection Rate and Accuracy

One of the standout features of this machine is its high inspection rate, combined with an impressively low false alarm rate. This remarkable efficiency translates into faster production cycles while maintaining a consistently high level of inspection accuracy.

Precision on a Granite Platform

The Online AOI Inspection Machine is built on a granite platform, a material renowned for its exceptional stability and precision. This foundation enhances the machine’s ability to deliver reliable and accurate inspection results consistently.

Advanced Lighting and Lens Technology

Equipped with programmable RGB+W LED lighting sources and bilateral telecentric lenses, this machine excels in capturing high-resolution images with low distortion and an extended depth of field. This combination ensures that even the tiniest defects are detected with precision.

Streamlined Programming and Interface

The machine’s programming flow is designed to be simple and intuitive, with a user-friendly interface. Batch modifications of parameters can be effortlessly achieved with a single click, making setup and operation efficient and accessible to operators of varying skill levels.

Centralized Control and Equipment Interconnection

The Online AOI Inspection Machine supports centralized control, allowing seamless interconnection with multiple pieces of equipment. This integrated approach streamlines production processes and promotes data exchange, contributing to overall efficiency.

Tailored Configurations for Varied Demands

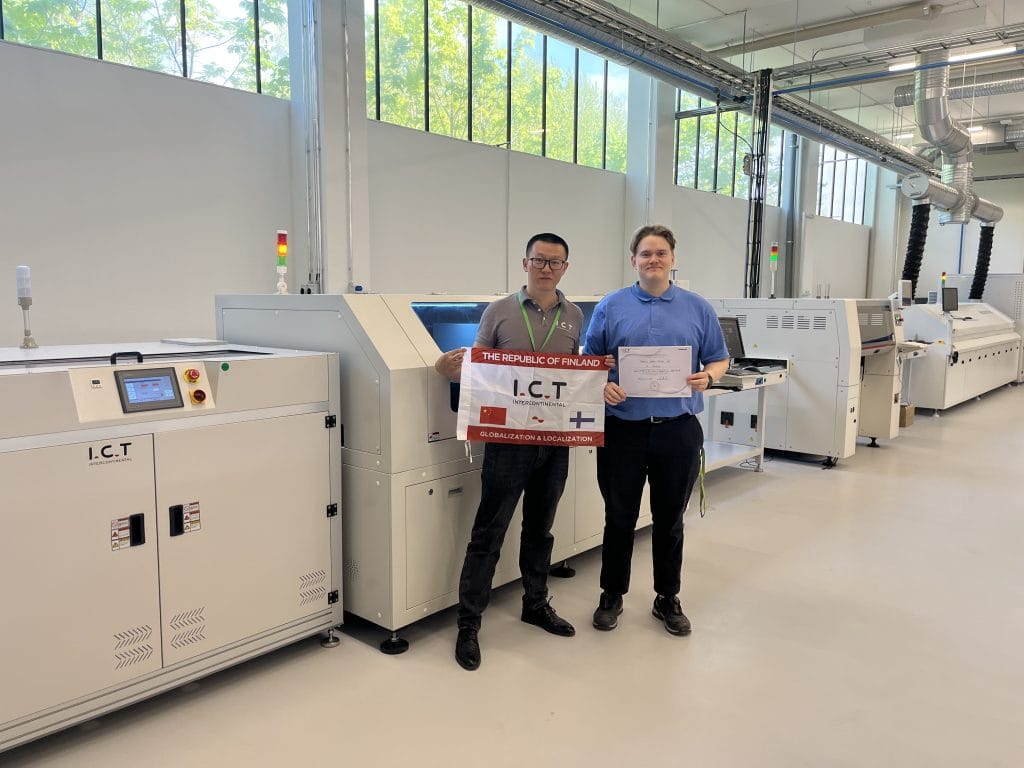

Recognizing the diverse needs of different industries and applications, the machine offers multiple configurations to meet specific inspection demands. This adaptability ensures that it can be effectively deployed in a wide range of manufacturing environments.

Comprehensive Inspection Capabilities

The machine’s inspection abilities encompass a broad spectrum of defects, including insufficient soldering, short circuits, soldering holes, solder-covered pins, contamination, misalignment, missing parts, skewed components, billboard defects, side-mounted components, overturning, wrong parts, damaged components, floating components, polarity issues, pseudo-soldering, empty solder, excessive glue, and more.

Outstanding Stability and Accuracy

With a Gauge Repeatability and Reproducibility (GR&R) of less than 10% at 6 Sigma and a CPK exceeding 1.33, the Online AOI Inspection Machine demonstrates exceptional stability and accuracy. Its test deviation accuracy is held to a remarkable ±0.25mm or less.

PCB Warpage Compensation

To accommodate the challenges posed by PCB warpage, the machine offers total mark compensation calibration and component position frame compensation, ensuring accurate and reliable inspection results even in non-ideal PCB conditions.

Traceable Data and Advanced Functions

Data collected by the machine is fully traceable, supporting Statistical Process Control (SPC) alarms, automatic log collection, storage functions, NG (Not Good) warning and alarm notifications, as well as remote programming and debugging capabilities.

Conclusion

In the dynamic landscape of electronics manufacturing, the Online AOI Inspection Machine stands as a beacon of innovation and efficiency. With its remarkable features and capabilities, it empowers manufacturers to produce high-quality, defect-free products while optimizing production processes. As the demand for precision and reliability continues to grow, this advanced AOI solution is poised to play a pivotal role in shaping the future of electronics manufacturing.

If you would like to know more about Online AOI Inspection Machine, please contact us.

Ask a question

FAQ:

Q1: What is an Online AOI Inspection Machine, and how does it benefit my manufacturing process?

A1: An Online AOI Inspection Machine is an advanced Automated Optical Inspection system designed for Surface Mount Technology (SMT) pre-reflow and post-reflow inspections. It benefits your manufacturing process by providing high-speed and highly accurate inspections, detecting defects early in the assembly process, and reducing the risk of shipping faulty products. This translates to improved product quality, reduced rework, and increased overall efficiency.

Q2: Can the Online AOI Inspection Machine adapt to different manufacturing needs and environments?

A2: Yes, the Online AOI Inspection Machine is designed with versatility in mind. It offers multiple configurations to meet various inspection demands, making it suitable for a wide range of manufacturing environments and industries. Whether you’re working with different types of PCBs or specific defect detection requirements, this machine can be tailored to fit your needs.