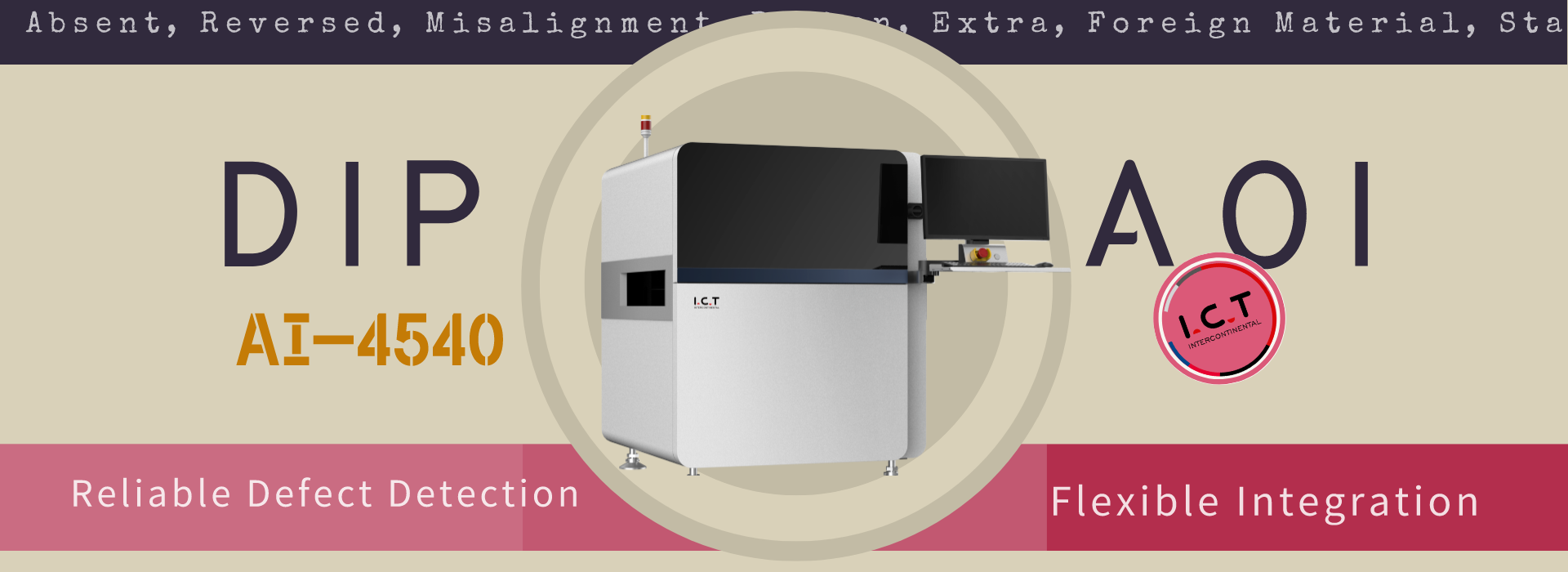

I.C.T AI-4540 | Inverted Camera Online DIP AOI Inspection Machine

AI-4540 DIP AOI Inspection Machine for precise SMT pre-reflow and post-reflow inspections. Benefit from high accuracy, advanced lighting, and a versatile lens. Its efficient programming, user-friendly interface, and centralized control ensure ease of use. Elevate your SMT processes with this comprehensive inspection solution. I.C.T offers a variety of AOI options for your selection:

Description

I.C.T AI-4540 DIP AOI Inspection Machine

Experience unparalleled precision in post-THT soldering inspection with our I.C.T DIP AOI Inspection Machine. This cutting-edge solution utilizes a high-precision color industrial camera to capture real-time board images. Powered by the Convolution Neural Network (CNN) algorithm, it intelligently processes images, enabling the machine to astutely identify and judge defects in components.

Feature for DIP AOI Inspection Machine

-

- Seamless Online PCBA AOI: Effortlessly conduct post-soldering inspections with our DIP AOI Inspection Machine, ensuring the highest quality for plug-in components.

- Precision at Its Peak: Experience a remarkable combination of a high inspection rate and an impressively low false alarm rate. Our machine automatically scrutinizes color ring resistors, capacitors, diodes, sockets, and more for flawless assemblies.

- Defect Recognition Mastery: Uncover defects such as wrong parts, missing components, reverse polarity, and other DIP element anomalies with the advanced defect recognition capabilities of our DIP AOI Inspection Machine.

- Line Continuity, Zero Interruption: Enable spanning erection without disrupting your production line, ensuring a seamless integration of our DIP AOI Inspection Machine.

- Effortless Programming and Interface: Embrace a simplified programming flow through an intuitive interface. Modify parameters effortlessly with one-key batch support, streamlining the setup process for enhanced efficiency.

- Unified Control Hub: Achieve centralized control and foster interconnection between multiple pieces of equipment, enhancing the overall coordination and efficiency of your production environment.

- Continuous Real-Time Insight: Keep your production line running without halting board movement. Our DIP AOI Inspection Machine provides real-time inspection, offering invaluable insights without interrupting the manufacturing flow.

- Adaptable and Portable: Enjoy the flexibility of easy mobility and adaptability with adjustable height and width features, providing convenience in different production settings.

- Swift Defect Localization for Production Mastery: Rapidly locate defects and maintain control over your production line, ensuring quick response times and minimal disruptions for optimized manufacturing.

- Versatile PCBA Size Compatibility: Accommodate various PCBA dimensions with options like Maximum 400300mm (12MP) or Maximum 520380mm (31MP), offering flexibility to match diverse assembly requirements.

- Data Traceability and Smart Features: Ensure traceable data with SPC alarms, LOG automatic collecting and storage functions, NG warning/alarm functions, and support for remote programming and debugging—empowering you with smart manufacturing capabilities.

Specification

- Inspection Algorithm: CNN, Color contrast, Outline recognition, Offset inspection, Template matching, Character comparison, OCR, etc.

- Inspection Item: Component: Absent, Reversed, Misalignment, Broken, Extra, Foreign Material, Stained, etc. Other: NG tracking bar(optional), Control box(optional), Mixed material inspection, Panel inspection.

- Special Function:Automatic search of elements and quick programming

- Resolution: 210um@ 49*41mm

- Inspection Speed: 0.23sec/FOV

- Camera: 5M pixel intelligent digital industrial camera

- Light: RGB+W light, 4 color integral

- PCB Size: 50*50mm~450*400mm (Three section track: 50*50-350*400mm, Single section track: 50*50-450*400mm)

- Rated Power: 520W

- Weight: 780Kg

- Dimension: L1125*W1160*H1340mm

Enhancing SMT Assembly Efficiency: Essential Equipment and Expert Support

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.

Additional information

| Model | I.C.T DIP Inverted Camera Online AOI AI-4540 / AI-4540L |

|---|---|

| FOV | 49*41mm |

| Camera | 5M |

| Mixing PCB inspection | Support calling program automatically. |

| PCB Size | Three section track: 50*50-350*400mm Single section track: 50*50-450*400mm |

| Operation System | Ubuntu 18.04 LTS 64bit |

| Display | 23.8 inch FHD display |

| Power | AC220 50/60Hz,5A |

| Communication | SMEMA |

| Weight | 780Kg / 890Kg |

| Dimension | L1125*W1160*H1340mm / L1125*W1410*H1340mm |

-300x300.jpg)