Good Price Automatic IC Burning Machine I.C.T-910

- High-Volume Programming Efficiency: Handles 8 work areas simultaneously to boost IC programming output.

- Modular and Customizable Design: Quick adapter changes for different IC types, including EEPROM and MCU.

- Advanced Detection and Protection: Multiple safety features ensure accurate and secure programming.

Description

I.C.T-910 | Automatic IC Burning Machine

Precision and Efficiency in IC Programming

The I.C.T-910 Automatic IC Burning Machine is a state-of-the-art, fully automated system designed to address the requirements of high-volume electronic production. Featuring a modular design, high-speed operation, and advanced capabilities, the I.C.T-910 offers an efficient and accurate solution for IC programming.

Why Choose I.C.T-910?

In the fast-paced world of electronics manufacturing, production delays caused by programming errors can be costly. The I.C.T-910 minimizes downtime by offering high precision and reliability, ensuring continuous operation. Its modular design enables quick transitions between projects, keeping your production line on schedule. Additionally, the machine’s customizable adapters accommodate a wide range of IC types, reducing the need for multiple programming systems.

The I.C.T-910 also lowers dependency on skilled operators. Its intuitive interface allows general workers to operate the machine with ease, reducing training costs and enabling high production efficiency with a smaller workforce.

Key Features:

- High-Throughput Programming: Efficiently handles large-scale IC programming with eight independent work areas, significantly increasing production capacity.

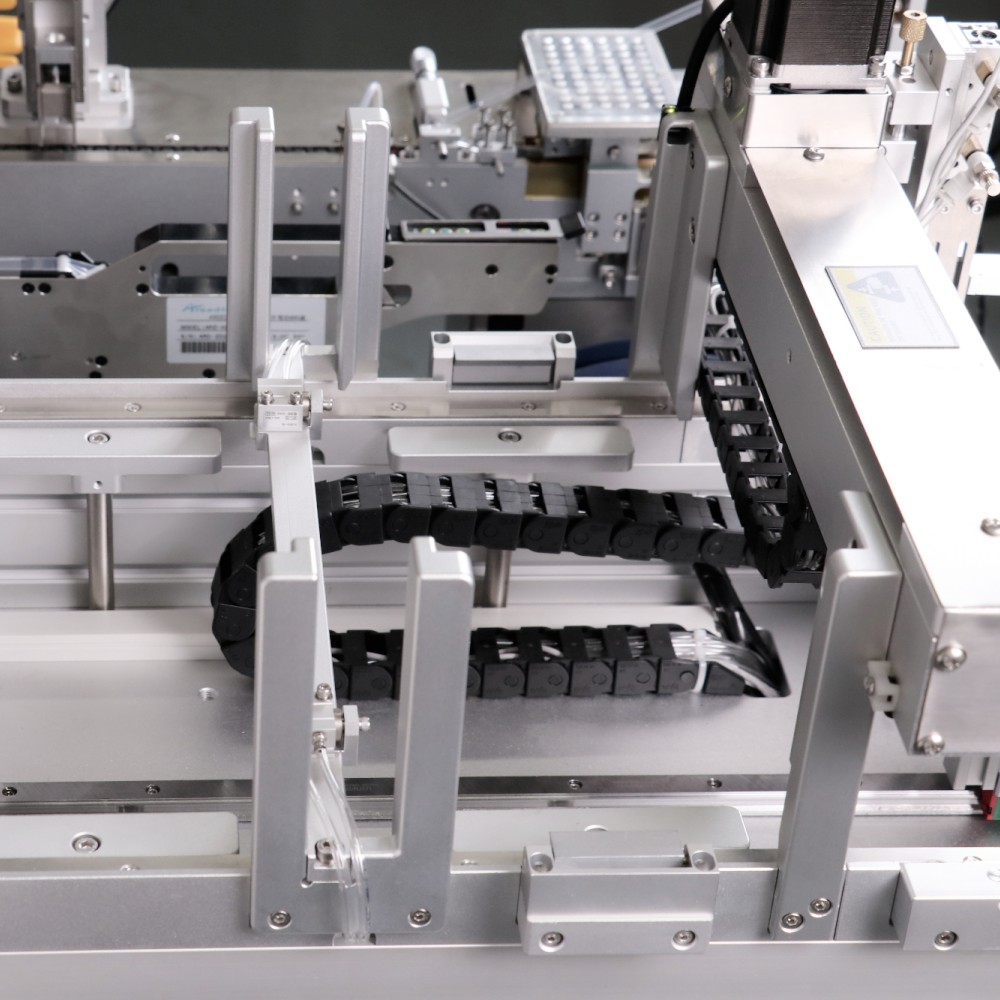

- Modular Flexibility: Quickly and easily switch between products by replacing programming adapters, minimizing downtime and maximizing productivity.

- Advanced Safety and Protection: Equipped with multiple detection mechanisms, including air source pressure, vacuum pressure, and component stacking, to ensure the safety and accuracy of the programming process.

- Customizable Adapters: Offers tailored programming adapters compatible with a wide range of IC types, including EEPROM, NAND/NOR FLASH, and MCU.

- Integrated MES Compatibility: Seamlessly connects with MES or lightweight CPS systems for streamlined report generation and traceability.

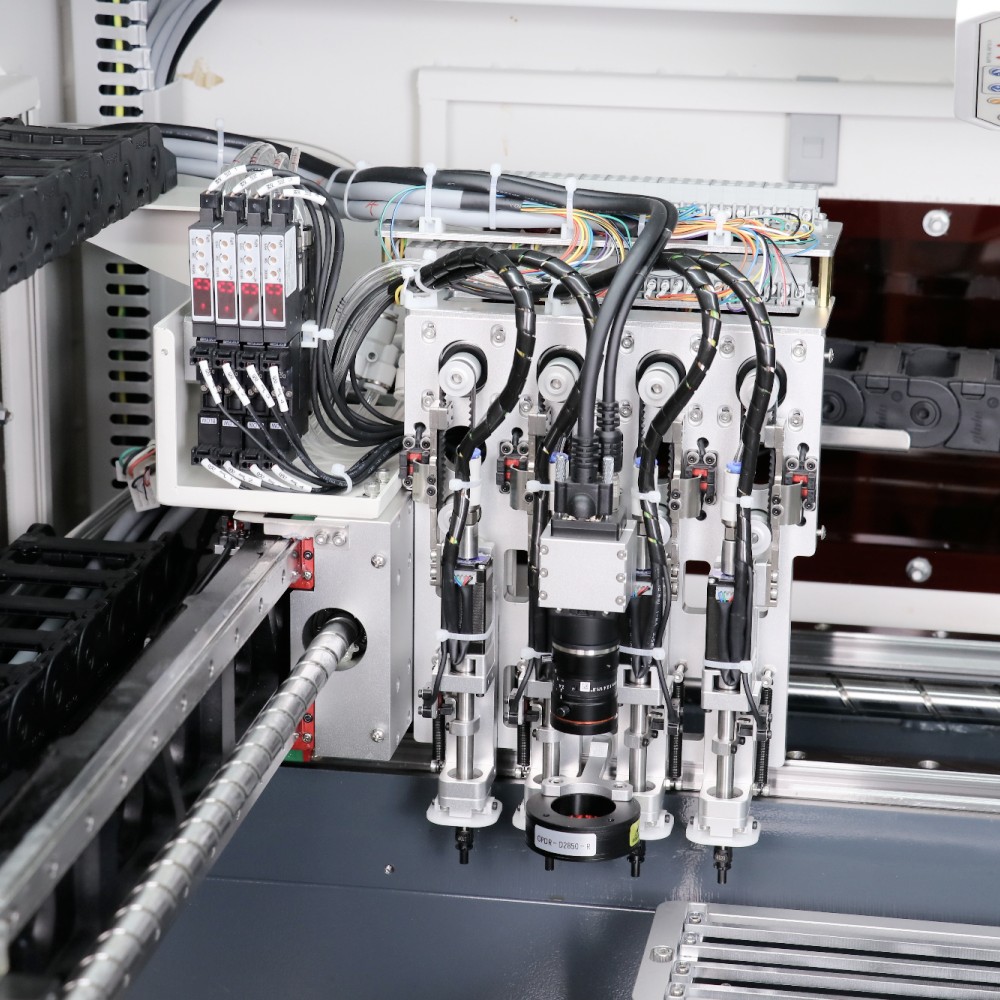

- Precision Programming: Features a Panasonic servo motor with ±0.015mm repeatable positioning accuracy for precise and reliable programming.

- Secure Packaging: Includes double heaters and pressing wheels to ensure secure sealing of packaging film, preventing component loss.

- Error Prevention: Automatic tray feeding and marking functions minimize the risk of misalignment and errors, ensuring consistent quality.

- User-Friendly Interface: Intuitive, modular, and layered operation interface with visual guidance, making it easy to operate without extensive training.

- Ongoing Support: Benefit from free system upgrades to ensure your machine remains up-to-date with the latest technology.

The Value of Investing in the I.C.T-910

Investing in the I.C.T-910 means acquiring a dependable and highly efficient solution for your IC programming requirements. By significantly reducing the risk of errors and minimizing downtime, this machine helps ensure a smooth and productive manufacturing process. Whether you’re producing small batches or large volumes, the I.C.T-910 is designed to deliver consistent results, making it a valuable asset for SMT production line.

Enhancing SMT Assembly Efficiency: Essential Equipment and Expert Support

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.

Feel free to reach out for any inquiries or specific requirements – we’re here to help. Our aim is to establish clear and efficient communication while offering prompt assistance. Whether you seek guidance or equipment, the I.C.T team is dedicated to promptly meeting your needs. At I.C.T, we are committed to ensuring a seamless and efficient SMT assembly process for our valued clients.

Additional information

| Model | I.C.T-910 |

|---|---|

| Dimensions | L1450*W860*H1450mm |

| Weight | 700kg |

| Efficiency of the machine | Standard machine: Equipped with universal burner of Puro and other brands: 8 sets of 32-64sit burners: UPH 2000-3000PCS/H; Equipped with 204AP brand universal burner: 3 sets of 12sit burners: UPH1600-2200PCS/H |

| Control precision | Precision servo screw drive, accuracy: X-axis ±0.015mm; Y-axis ±0.015mm; Z-axis ±0.03mm; P-axis ±0.03mm; U(θ)-axis ±0.15° |

| Suitable package form | PLCC, JLCC , SOIC, QFP, TQFP, PQFP, VQFP, TSOP, SOP, TSOPII, PSOP, TSSOP, SON, EBGA, FBGA, VFBGA, BGA, CSP, SCSP, and so on. (Open Top adapters, some ICs need to be customized with special adapter consumables). |

| Nozzle | 4pcs |

| Camera | 2pcs (Component camera + Marking camera) |

| Feeder station | 2pcs (8-24mm) |